Hinge Jigs

Not every door is prehung, so we evaluated nine single-hinge and full-length-hinge router templates to choose the best.

Synopsis: Although many new doors are available prehung, not all of them are. When you need to hang a door that hasn’t been mortised, it’s time to grab a hinge jig. With a router and a hinge jig, making mortises is fast and accurate. In this tool review, finish carpenter Kit Camp tested a variety of devices, including both single-hinge and full-length-hinge jigs. Among four single-hinge jigs, Camp rated a Templaco tool as best overall. Among six pricier, full-length-hinge jigs, Camp placed a Trend model at the head of the pack. This article also includes a sidebar in which Camp lists his best tips for door-hanging.

Though I don’t do it full-time, hanging doors has always been a mainstay of my business, and doing a fine job on a customer’s doors has often led to other work. Although most new homes today are built with prehung doors, hanging them from scratch is still a skill in high demand for both new custom homes and remodels of historic homes.

Mortising doors and door jambs for hinges was traditionally done by hand with a chisel. Today’s router jigs, though, are faster and more accurate. For this review, I looked at a wide variety of both single-hinge and full-length-hinge jigs made from metal, plastic, and plywood, from several manufacturers and covering a wide price range.

Testing procedures

I started by unpacking each jig and reading the directions, which were of a much higher quality than I have come to expect of tool manuals. After assembling each jig, I routed a test mortise to see how it worked and to make sure it would work for the hinges I was using.

For the first round of tests, I used each jig to make mortises for 3-1⁄2-in., 4-in., and 4-1⁄2-in. hinges from a few different manufacturers. Virtually all the hinges I use in my work are either square-cornered or have a small 1⁄4-in. radius at the corner. Many of these jigs also make mortises for hinges with a 5⁄8-in. radius corner, but I have seen these hinges only on inexpensive, prehung doors.

After making sure the jigs worked as they were supposed to, I used each to mortise a pair of standard 80-in. doors and jambs, which I then pieced together. Once joined, I looked at how well the hinges aligned, and whether the backset and the head gap of each pair matched.

To see how well the jigs handled doors with fewer than three hinges or that were shorter than 80 in., I mortised a blank made from a carefully dimensioned 2×4 to fit into one of the jambs in my 1920s house, which features 78-in. doors hung from two 3-1 ⁄2-in. hinges. This test allowed me to see just how adjustable the templates really were when they were being used for a nonstandard layout.

My preconceived notions were wrong

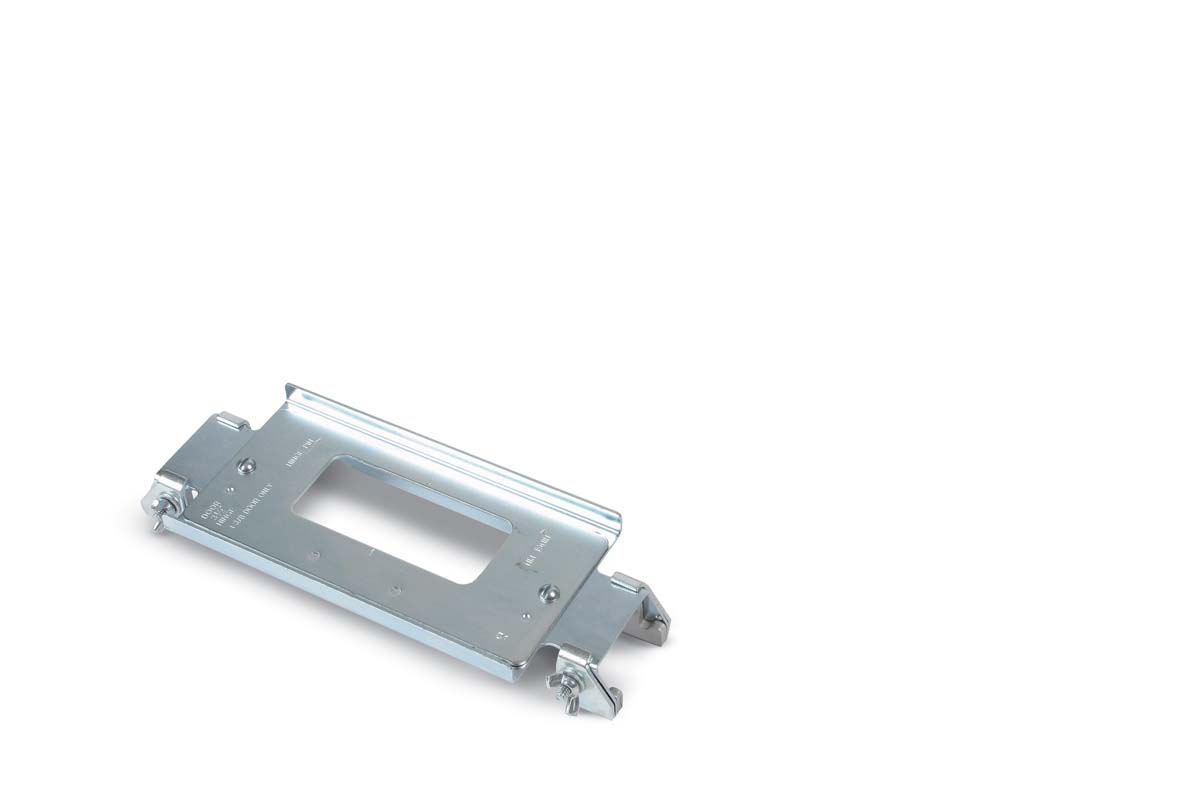

I’ve never owned a full-length, adjustable metal hinge jig but had always coveted them as a tool “real” door hangers used. So when I put them head-to-head against plastic and plywood jigs, I was both surprised and disappointed to find that I just didn’t like the metal jigs very much. To me, they were overly complicated, prone to malfunctioning, and not as impressively constructed as I expected.

If I had to choose a metal jig, it would be either the Bosch or the Milwaukee (which are essentially identical) because of their ability to be fine-tuned to create uncommon mortise sizes. But unless I really needed the adjustability of this style of jig—consistently hanging new doors in old, nonstandard jambs, for example—I would stick with a fixed, full-length template.

Of the single-hinge jigs, I prefer the HingeMate hands down. It is beautifully made, highly

adjustable, and produces flawless results. I would love to have one in my shop. For those on a budget and for carpenters needing the ability to rout jambs in place, the Templaco is hard to beat. It’s inexpensive, simple, durable, and reliable. Each hinge size is sold separately; just buy the sizes you need, as you need them.

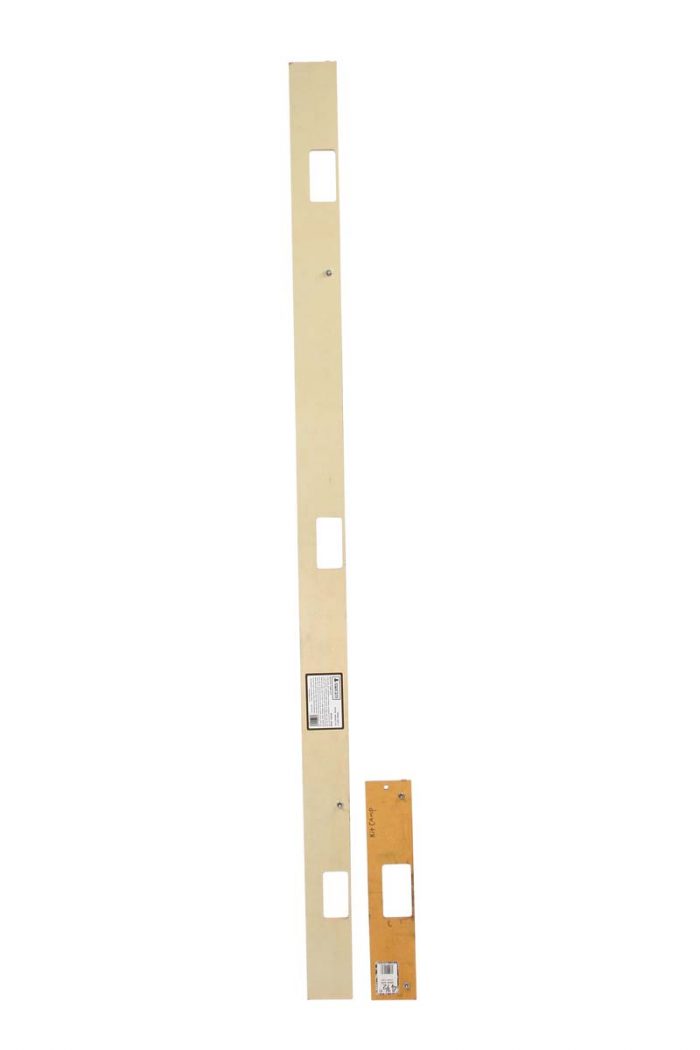

The Trend was my favorite of the full-length jigs. It has all the advantages of a fixed template—simplicity, durability, and a minimum of loose parts—but it is also adjustable for different-size hinges. For those willing to make the investment, this jig will handle most door jobs with ease. For those on a more limited budget, I would again choose the Templaco. Like the single-hinge model, the full-length Templaco jigs are designed for only one size of hinge, but they are inexpensive and foolproof, and have served me admirably while hanging hundreds of doors.

Single-Hinge Templates

These jigs generally require you to measure and mark out the mortises on the door and the jamb, and then position the jig over each mortise to be routed (typically three mortises on a standard 80-in. door). The disadvantage is obvious: The jig must be moved a number of times to complete the mortising, with each of these movements taking time and introducing room for errors. With precision being paramount to good door-hanging, these single-hinge jigs would seem at an obvious disadvantage to the multihinge models. Their simplicity and low cost, however, make these templates appealing to carpenters who hang doors only rarely or to homeowners working on their own projects. With careful attention to layout, the end results are just as good.

Full-Length Jigs

These more complicated and more costly jigs are aimed at professional door hangers and finish carpenters who might be hanging a house full of doors all at once. Once set up correctly and positioned accurately, these jigs allow you to rout three (or sometimes four) hinges into the edge of a door or into a jamb very quickly, with less chance for error. Repeatability is their primary asset.

The Bosch 83038 and the Milwaukee 49-54-0101 templates are identical except for the knurling on some knobs, so I will consider them together. The templates are easy to set up for pretty much any standard layout without using a measuring tape, and they accommodate a wide range of door thicknesses and hinge sizes. All the necessary sizing information is scribed into the parts for common door sizes and hinge spacings. There are fixed positions for each common hinge size as well as an adjustment for fine-tuning these sizes. Once the templates are set up, no measuring is necessary. The mortises produced should be consistent, whether you are doing one door or many.

Despite their beefy appearance, though, both jigs gave me problems. The rotating hook that positions the Bosch guide on the door or jamb was riveted crookedly, preventing it from rotating correctly. I tried to bend it into alignment, but couldn’t. Luckily, the jig comes with two hooks for different hinge spacings, so I was able to substitute.

On the Milwaukee, two screws that hold one of the hinge-adjustment pieces were stripped right out of the box. I retapped the holes for a 10/32 machine screw, but I don’t have much confidence in the flimsy metal used for this part of the jig. Worst of all, one of the pins used to set the size of the hinge vibrated loose while I was routing, ruining my bit, chewing up the pin, and wrecking the mortise. A flaw like that could easily ruin an expensive door.

The enclosed rails were too long to match the template to the short jambs in my house. I matched the mortise positions by eye and got excellent results, but substitute rails could easily be made from hardwood scrap. Bosch sells simple aluminum blocks as an accessory that screw into the old mortises and allow you to line up everything without guesswork. Again, something similar could be made from wood. I know many full-time finish carpenters who use the Milwaukee or Bosch jig for all their door-hanging.

Bottom line: The big advantage of these jigs is their versatility. Having one in your truck or van means you could tackle any job that might spring up. To me, though, there are too many things that could go wrong with these jigs at any given time. If any of the dozen screws or knobs were to vibrate loose, it would be a total failure. I expect better from jigs this expensive.

|

|

Tips That Go Beyond the Jig

Years of door-hanging have left me with a long list of hard-earned lessons. Here are a few tips to make your jobs go more smoothly.

• Prevent chip-out on the edge of the door or jamb by making a shallow cut along the outside edge before moving the router farther into the wood.

• When transferring hinge locations from jamb to door, or vice versa, use a story stick marked with the hinge locations. Don’t forget to figure in the head gap; a nickel makes a good spacer.

• Router bits are round, so they make round-cornered mortises. If you’re

using square hinges, the mortise must be finished by hand. Spring-loaded corner chisels are seldom sharp enough to do clean work—especially in softwoods—and are hard to hone. A sharp 1-in.-wide chisel is best.

• Precise mortise depths are especially easy to achieve using a plunge router. Just place a hinge leaf between the router’s depth rod and depth stop; then clamp the depth stop in place.

• Hinges are not always exactly their stated size. If the mortises are coming out oversize, add a couple of layers of blue painter’s tape to the inside edges of the template, or wrap tape around the guide bushing for nonadjustable metal templates.

• A self-centering drill bit to pilot hinge screws will save time and aggravation.

• I don’t have room to store a full-size door bench, so I spent an hour making a simple wedged door buck from birch. Trend and Templaco sell similar bucks, too.

• To avoid mortising the wrong side of the door slab, I use a trick I picked up from Fine Homebuilding author Gary M. Katz. I make a large X on the face of the door nearest the top hinge barrel. Use masking tape for stained doors.

For more photos and details, click the View PDF button below

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Handy Heat Gun

Affordable IR Camera

Reliable Crimp Connectors

View Comments

I could not locate this back issue, so access FH web site archives was a boon. Kit Camp is shown using a door buck. Are the plans for this jig also available online? Thanks.

You can reach me at the following e-mail address:

[email protected]