Dryer-Vent Scrubbie

This easy-to-make tool will help keep dryer vents clean and damage-free.

A bird somehow managed to thwart the spring-loaded damper at the end of our dryer’s 15-ft.-long vent line. Then it built a nest and the duct started to collect lint—lots of it. Before buying a dryer-vent brush to clean out the lint, I decided to look around my toolshed to see if I could cobble one together with available materials. The brush had to be strong enough to dislodge the lint, yet flexible enough not to break, tear, or puncture the corrugated vent line.

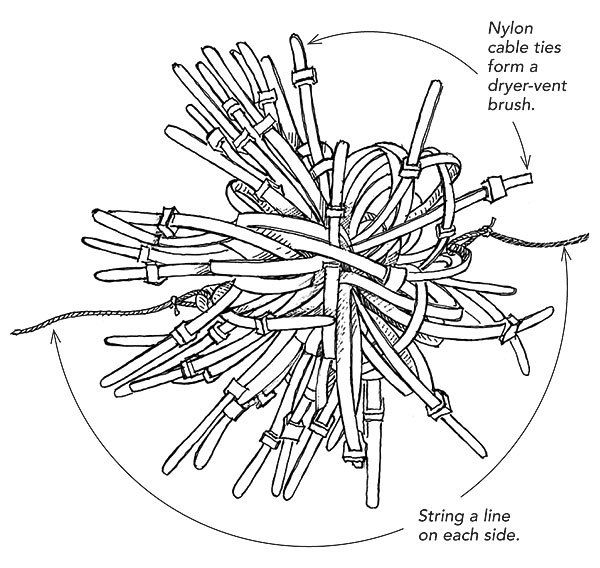

I came across a bag of nylon cable ties and clipped a bunch of them into individual loops. Then, using another tie, I clipped them all together to make a sort of textured plastic ball, as shown in the drawing above. For handles, I tied two 20-ft. lengths of sturdy twine to each side of the ball.

I was able to run my electrician’s snake through the clogged vent line, and I tied one end of the twine to it. I pulled the ball back and forth through the vent several times, dislodging all the blockages without any damage to the vent. I put a new flapper cap on its end, and we were back in business.

— Bob Miller; Titusville, NJ

From Fine Homebuilding #213

RELATED STORIES

Got a Tip?

Do you have any great tips like this one on how to make a dryer vent cleaning tool that’s totally DIY? Share your methods, tricks, and jigs with other readers. Tag them @FineHomebuilding on social, email them to us at tips@finehomebuilding.com, or upload them to FineHomebuilding.com/reader-tips. We’ll pay for any we publish.

View Comments

Where I’m from we can’t use nor would I recommend that flex for a dryer vent. Always use ridged. Also ridged only for bath exhaust fans. Flex = bad news

@rjhome: agreed, use rigid duct work, not flexible. Flexible adds to fire hazard with lots of places for lint to get caught. A tip for rigid duct: don't use screws to connect it because they'll project through and catch lint. I use foil tape.