My company just completed a whole house interior remodel of a 1950’s house in Austin, TX. The client sourced some 1×10 shiplap pine boards that were used for sheathing in a former life. My finish carpenter took those boards and milled them into flooring. You’ll see the new Amana Tool 3/4″ hardwood tongue & groove router bit set at work. The floor looks amazing and has a great story to tell too.

– Matt Risinger

View Comments

just wondering, how was the flooring put down, on ply, glued to concrete, etc?

Long Leaf Pine flooring is indeed beautiful. My wife and I used it in our retirement apartment. We, however, had some leftover double-sided bead board, single-sided bead board and 1X12" 14 foot long planks that we'd like to sell. How much is that kind of stuff worth? Our pine was taken from two 120 year old buildings where our apartment is located.

What did you do in regard to nail holes, i.e. did you fill them and if so with what product? I have stockpiling a fair amount of fir (which was used as paneling in my garage) and intend to turn it into a floor. It is not as thick as the pine - any thoughts on the minimum thickness for a solid wood floor? Also any thoughts on gluing strips together for a floor?

Thanks!

no underscore this floor is doomed.

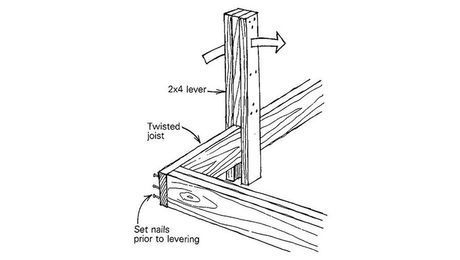

Underscoring is just some kerfs in the bottom of the flooring correct? What exactly will happen without them??

I noticed that all the milling was done in the house.

I think that is a bad idea.

That must have created an incredible amount of dust.

That dust would have gotten into every crack and crevice and light fixture.

The dust would have also stuck to the ceiling and walls.

Absolutely every square inch of that house would have to be dusted.

@mgaudet: This is a 50's slab house we remodeled so we laid visqueen on the slab, then shot 3/4" CDX down. Next was a layer of 15lb felt and this floor was nailed (and some trim head face screws) down.

@johnmocha: So for the nail holes we filled them with black epoxy then sanded and finished the entire floor with an oil based poly for the ambering. In regards to glueing up the floor strips, I'm not sure what to tell you, sorry.

@nvman: This was a total house remodel so no clients in the house. We covered the vents and went to town. Lots of shop vac work when we were done but the rains outside didn't affect us! Also, no relief kerfs underneith. It's only been down and finished for 6 weeks but so far so good. We did a double vapor barrier underneith the floor, hoping for the best on that...

Love the reclaimed pine, but I would have had a company who specializes in milling flooring do the milling. I have several concerns on the in house milling operation; one is the missing relief cuts mentioned by others, two is did the carpenter pay attention to which way the growth rings were facing when milling, and three did the router bits also joint the edge as they milled the tongue and groove edges. From the finish look on the video it looks like the entire floor was screeded with the black epoxy wood filler, because I see a lot of dark lines along the board edges and that's why I asked if the router bits used also jointed the edge or if the jointed edge was just produced by the job site tablesaw. If the jointed edge was produced by the tablesaw this will leave an inferior jointed edge and cause gaps along the edges that would have to be filled and once the wood starts to move from seasonal humidity changes this filler will most likely be pushed up and out between each board, not to mention the cupping problems that may occur from the lack of relief cuts underneath and if proper crowning of the growth rings wasn't done by the carpenter when milling. The good thing is that the wood is very very old and much more stable because of this. After all that being said this floor might last a lifetime with no problems at all.