The Second World War caused a dramatic change in how and where we lived. For one, many veterans from the frigid parts of our country trained or passed through southern states and liked what they saw. I know it happened to my older brother, Jim. Come war’s end he, along with many thousands of other war vets, had no desire to return to their home states.

They found the mild climate in places like Southern California to be quite preferable to the harsh, long winters they experienced as young men and women. This, along with plentiful jobs, caused a massive movement of people relocating from north to south.

In the span of 15 years after the Great War nearly 750,000 people moved into the San Fernando Valley alone.

This migration, in the late 1940s and 1950s resulted in a demand for housing unparalleled in our history and was a major cause of the revolution in construction that took place (FHB 177, p 96-101). Everything had to change. Tools, methods, and materials that were used in the construction trades from the time of the Civil War had to be laid aside in order to meet the housing needs of these on-the-move veterans and their families. Endless numbers of new houses needed to be built rapidly.

Better than a handsaw. In 1951, I got my first power saw, a scary-looking sidewinder with no lower guard, made by Sioux Tools. Within a year, I switched to a Skil Model 77 worm drive, which became standard equipment for California tract builders.

A new generation of tools — The old building methods, many of the materials, and even the razor sharp tools in every carpenter’s kit that had been handed down from father to son were fast becoming museum pieces. The handsaws that had been used by many generations of carpenters were replaced by the power saw. Braces holding bits for drilling holes in wood members were laid aside for the electric drill motor. Short-handled 16 oz. hammers were replaced by long-handled 22 oz. California framing hammers.

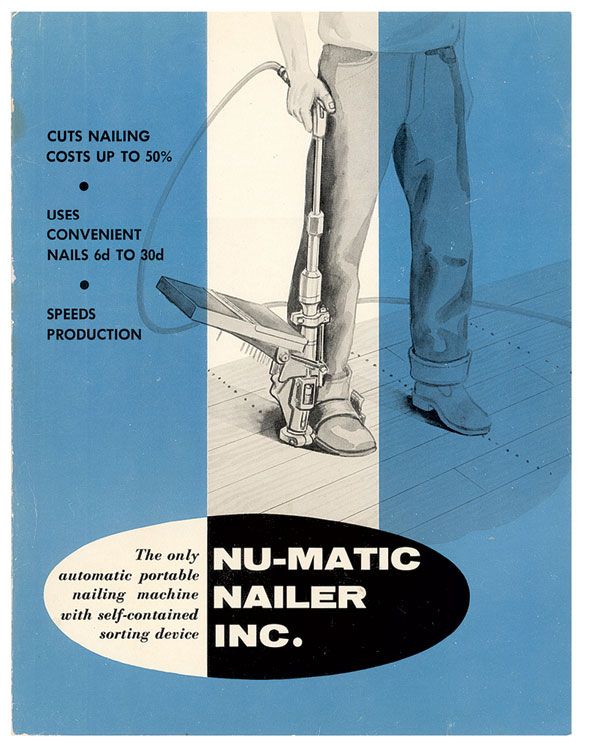

Then air operated nailguns allowed carpenters to leave their hammer hanging from their nail belt. The wooden folding ruler was replaced by a retractable metal tape. Jeans became the work uniform of the day rather than the white, bib overalls with their numerous pockets to hold a variety of tools and nails.

The traditional tools worked great to craft one-house-at-a-time. They were inadequate when we were charged with building five hundred in a row.

A new generation of carpenters — One of the unforeseen results of this need for mass production was that we carpenters became specialists instead of generalists. I was trained by master carpenters. They taught me how to build an entire house. We dug the trenches, set batter boards and foundation forms, mixed and poured the concrete, framed the house, installed the siding and roofing, and completed the building process until the last door was hung and the last cabinet built and installed. Our foreman then handed the key to the new owners. We were general carpenters and contractors, but believe me, “The times they were a changing.”

Work on this production line demanded that we all become specialists. Was there really any other way? Henry Ford used the production line to give us all an automobile. We took this same production line to the jobsite so masses of people could actually own their own home. Overall construction time had to be reduced from many months to weeks or even days. This was done by sub-contracting different parts of the building process to men and women who specialized in doing one aspect of the work. We were called piece workers or labor contractors.

>One at a time takes too long. Housing demand was so great in the 1950s that tract builders used every trick they could to build faster and more efficiently. Cutting multiples was a common theme. Here, an entire roof’s worth of rafters has been ganged up, and I am cutting the bird’s mouths using a worm-drive saw with a swing table

>One at a time takes too long. Housing demand was so great in the 1950s that tract builders used every trick they could to build faster and more efficiently. Cutting multiples was a common theme. Here, an entire roof’s worth of rafters has been ganged up, and I am cutting the bird’s mouths using a worm-drive saw with a swing tableWe were often paid not by the hour, but by the piece — by how much we actually produced — by how many sq. ft. of walls we framed, for example. This approach unleashed a torrent of resistance along with another torrent of innovation and increase in productivity. Resistance came from unions that feared loss of work and from those workers who were just fearful of change. Innovation and increased production came not from having to work harder, but from simply working smarter. Most of what I know about production framing, and doing finish work for that matter, came from those times and endures through today.

When you have 500 level lots ready to go, you can go down the line staying busy doing nothing but setting concrete forms. Remember, this building boom went on for about thirty years. As framing contractors we worked on the job site, but much of the work was done by others. Fernando Ochoa, long dead now, nailed floors, shear walls, and roofs behind us framers for 30 years. Bob Harter set door jambs and window frames for 25 years. Ernie Wulken did the pickup work (punch list) forever it seems. All were highly skilled—masters of their part in building a house.

And so it was. Every project was broken down into its many parts and subcontracted out to willing workers. Instead of being a general carpenter you became a form setter, a joister, a floor sheather, a nailer, a person who did wall layout, a person who cut cripples and headers, another plated the walls, then came the wall framers, a roof cutter and stacker, a shingler, and on and on, a jamb setter, a door hanger, a cabinet installer.

For a time, I worked with a man who only did layout for walls on the subfloor—one floor after the other. I learned a lot from him. He knew that part of the trade quite well. Yes, the production line is an efficient way to build.

When you are working by the piece, your mind is constantly trying to figure ways that your work can be done easier, quicker, and more efficiently without having to work harder. New tools came into being and new ways of working seemed to appear like magic as workers came up with innovative ways to do their job.

Those of you who frame using a layout stick, a corner and channel marker, a bolt marker, a sidewinder saw that can cut flush (www.bigfoottools.com), and many innovative production methods can know that these came into being some 60 years ago.

Larry Haun

July, 2010

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Handy Heat Gun

Reliable Crimp Connectors

Affordable IR Camera

View Comments

Excellent storytelling, Larry...as always. Please keep it coming!

Awesome blog post, Larry. I'm here on the east coast with lots of older houses that are in need of attention and where the skill sets has to be broad and deep to handle what needs to get done if it is to be done properly. While there is still production building going on, there is heaps of renovation and remodeling where assembly line skills aren't enough. The trouble is, there is very few skilled tradesmen left. The work turns?

This really needs to be developed into a full-length book on the history of the building boom in California, one that ties together the social history with the development of revolution in housebuilding. Only someone with your hands-on experience would have the knowledge of putting this together, a university-trained historian wouldn't have this kind of intimate knowledge. I should know, I'm a university-trained historian who happens to have built my own house!

But I loved the post, we need a lot more of this. If you can talk Taunton Press into backing a history of this kind, I'd be more than willing to assist with the project, it would make a terrific book.

I was working with my son on the wife's car yesterday and was pleased that he, with a degree in poli-sci, still knew how to work a spring compressor. Passed on from father to son. He then told me he was buying a house and needed help on the remodeling of same. Adding a second story. Passed on from father to son. In this day and age of instant communications and specialization, it is comforting to know how we got here and how to live self-sufficiently.

This is an intriguing glimpse into the era you refer to as well as the methods used. I agree with Spinosa2. If you ever get around to writing it, I will gladly purchase a copy of the book. Don't forget the pictures. They really help tell the story.

Regards,

Matt

Times have changed so much. Now the homeowner is looking for very good handymen or master carpenters of old to do renovation, weatherization, and other custom modifications. This history is excellent to sketching how a "piece work" era after the war came into place, and now we are seeing the real end of that era and maybe the destruction of the new home market. It is not a pleasant time. Maybe we will begin to see the resurgence of the "master crafts-person" and many home owners like me will finally have access to talent and resources.

Thank you, Larry. Ill bet there isn't a day that goes by without my having not applied one of your techniques in homebuilding. Your mastercrafstmanship is reflected in your ability to teach and inspire. Equally interesting to hear your recollection of the evolution of homebuilding. Mahalo, Jeff

Great article, Larry. This is a history few know and it is important it be preserved. Please write more, especially about your personal experiences of the post war boom in California and the change to production framing methods. As the division of labor became more differentiated, what was your specialty? In a way, I think perhaps carpentry became more democratized as the exclusive 'master-craftsman' mentality of the trade unions was replaced by the pieceworker phenomenon. Keep up the good work, Larry.

Great history lesson, Larry. Nicely done. My feelings and observations trend with richard904 and my livelihood as a carpenter/ contractor depends on the demand for diverse abilities. People looking for "one-stop shopping" in their contractor. Interesting how demand seems to be coming around, full circle.

Looking forward to more of your posts.

Matt

The Timber Tailor

Great post, Larry! In our design/build remodeling business we try to take advantage of some of the innovation and efficiency of specialization while creating very custom kitchens and baths. We do this by focusing on design and project management (our specialty) and hiring specialized subs when possible. It beats trying to do everything yourself, but the level of efficiency you describe must have been amazing!

Good concise history.

I started in 1970 in Westlake-Thousand Oaks racking horses for Rodger Wiggins, a roof cutter. I did the apprenticeship and stacked then cut and rolled a ton of truss.

Even coming in late it was an interesting time. Hippies were becoming carpenters!!

Look forward to more history.

hello my name is Thomas McKibben and i am in a Technical School called Commonwealth Technical Institute in Johnstown PA and i am studying building maintenance and we have watch all your videos we are a big fan and we your instruction on framing roofs, floors and stairs, walls and i was wondering if u can do us a big favor i was wondering if u can come and give our class a lecture on your career we would really appreciate your presents in our school you can email me @ [email protected] we would be really grateful

sincerely,

Thomas McKibben