How to Make a Stealth Soffit Vent

This builder explains how he decided to go with wood-framed, epoxy-coated screen vents for this garage soffit issue.

The construction market is on fire here in South Florida, especially in the residential renovation segment of the custom home-building business.

Not really! Up until a few years ago we, like many construction companies and design builders, were focusing on high end residential renovations with fancy fit and finish and had permanently left the days of building garage additions far behind us—we thought. Last year, an architect friend called me and said she was too busy to do a carport-to-garage expansion for one of her neighbors. She asked me to meet with the owners and consider designing and building it for them. My projects were winding down and so I met with the owners and we began work on the project.

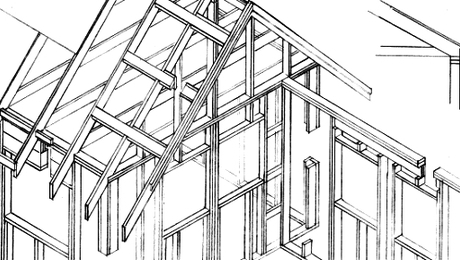

The existing residence is a split level 1950s vintage, tract, vacation home in downtown Fort Lauderdale. It is constructed of concrete block with a stucco finish and heavy timber, conventionally framed roof system. Our garage needed to match the existing house, duplicating as many of the existing construction details as possible, including the heavy timber roof construction, and fancy gable. Original houses of this style typically have stucco enclosed soffits or bird blocking. Either one works fine for the conditioned interior space of the house but would make the garage unbearably hot here in Fort Lauderdale. Some type of soffit venting would be an absolute requirement of this project.

Exploring the options for a stealth soffit vent

We considered a number of alternatives before settling on the detail shown here. Stucco soffit venting techniques were ruled out immediately because there was no precedent for them in this residence with its heavy timber rafter tails and exposed T&G roof deck. Additionally, we find that over the course of 20 – 30 years, the screening separates from the frame or rafter it is attached to and is very difficult to repair without doing major surgery to the soffits, a situation we always try to avoid. We also considered a variety of manufactured solutions including PVC T&G ventilated soffit, which is very slick, and would have looked nice, but again, would have been inconsistent with the rest of the house. We looked into Cor-a-Vent, another really nice product, and almost decided on it as our perfect solution. I had some fears about it turning into the ultimate beehive / insect hotel due to the nice small holes that make up the ventilation system. It comes in white and black and a variety of depths which can be detailed to be nearly invisible. The simplest installation of Cor-A-Vent appeared to be using their Raft-A-Vent product on top of traditional bird blocking, which would have made maintenance relatively simple. Ultimately, we passed on it too.

So what did we do?

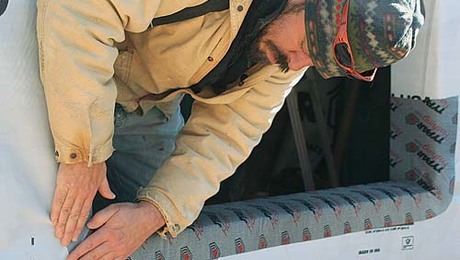

We decided to site-build individual, wood framed, epoxy coated screen vents, and install them in place of traditional bird blocking. It turned out that he spacing between the heavy timbers of the existing carport roof was 19 5/8” OC, a standard for the time this house was built. The spacing accounts for the 4x dimension of the heavy timbers and the T&G decking. Needless to say, my guys, none of whom were born when this house was built, were sure the “old craftsmen” of the day had one too many on their lunch break and set the members wrong. We used the same spacing just to add to the job-site confusion. This solution required a variety of different size vents, plus the irregular size ones at the end of each run.

Despite the unique sizes of many of the vents, this solution accomplished all our major objectives for this detail. We provided more than double the amount of ventilation to the garage than any other practical solution could provide. The vents are aesthetically consistent with the existing building and are extremely low maintenance. They are double screened to keep out bugs and are sturdy enough to survive the test of time and the South Florida weather. The epoxy coating on the aluminum screening won’t rust and they are painted to match the heavy timbers and exposed T&G decking.

Because of the way we installed them, the screens are easily removed, repaired and/or replaced. We attached a 1×2 poplar cleat to the bottom of each rafter, tight to the wire mesh, prior to scratch coating the stucco. The cleat provided a solid ground for connecting the vent and a positive stop for the stucco both inside and outside the garage. Leaving a reveal at the edge of the cleat, provided an easy joint to caulk and paint, adding to the finished look of the vents and the 1 1/2” dimension of the cleat allows the vent to stand clear of the stucco, and eliminates an unsightly ragged edge where the stucco ends.

Would we do this again?

The homeowners really love the look of the detail and I’m pretty happy with it as well. My trim carpenter enjoyed building it (why not, he’s paid by the hour!) and the painters didn’t complain about it too much — a de facto approval. After adding up the cost of building and installing the vent detail, the final tally came in at just over $760.00. For this project, that number is just over $30 /sf of vent. That sounds pretty high. In the scheme of this very custom carport to garage conversion, it’s a drop in the bucket. On a larger project, we should be able to develop some efficiency and reduce the cost per foot, but it’s unknown by how much. Maybe we’ll look at the Cor-A-Vent solution harder next time and see what we can do about discouraging the bugs from moving in. But, for this project, I’m happy with the detail and the Owners are too.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Get Your House Right: Architectural Elements to Use & Avoid

All New Kitchen Ideas that Work

Code Check 10th Edition: An Illustrated Guide to Building a Safe House