What's the Difference: Granite Finishes

Polished, honed, leather, flamed, and river-washed

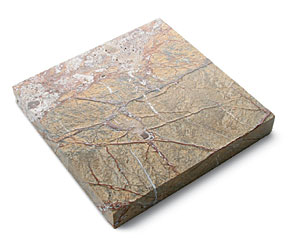

Because it is one of the hardest rocks on earth and isn’t affected by high temperatures, granite is a popular choice for kitchen countertops. Its uses extend beyond the kitchen as well: bathroom vanities and tile, fireplace surrounds, and outdoor walkways, to name a few. Granite is available in a variety of finishes, and if you’re buying or installing it, you need to know what makes these finishes different from each other.

Polished

This finish provides the smoothest, most reflective surface, and it brings out the granite’s color and pattern more than any other finish. It’s also the least porous, a useful characteristic if your countertop is likely to catch some spilled wine or beet juice from time to time. A polished finish is by far the most popular. It’s also the easiest to clean.

Honed

A honed surface is created by simply not taking the finishing process as far. The result is a surface that is still smooth, although not reflective and not as revealing of color and texture as a polished finish. The surface is somewhat more porous than a polished surface, but it will reduce the glare common to polished granite.

Leather

By moving diamond-tipped brushes over a honed surface, granite fabricators create a surface that looks and feels similar to textured leather. This process reveals more of the granite’s color and makes it less porous. Because it hides streaks and crumbs well, it can be a good choice for homeowners who are more informal about their kitchen cleaning.

Flamed

This finish is produced when a high-intensity flame is passed over the surface of the granite, causing some of the minerals to “pop.” Its rough surface makes it a poor choice for a countertop but a great one for outdoor use, such as walkways or stairs.

River-Washed

What granite dealers call a river-washed finish can be either of two finishes, which are created using completely different methods. The first method is a two-step process that begins with the creation of a flamed finish and ends with the surface being smoothed with wire brushes. The second method involves a high-pressure spray of water and sand directed at the surface, causing softer minerals to wash away. The result is a highly textured, uneven surface that is nevertheless smooth.

Photos: Dan Thornton