Labor-Saving Deck-Building Strategy

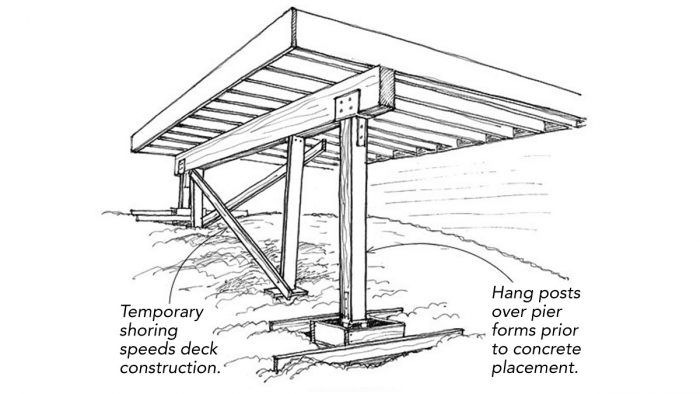

A temporary support beam lets you put deck forms in on day one.

The temporary beam support shown in the drawing reduced our cost by a day of labor. For contractors these days, this is a big deal — especially on a small job like this one.

Here’s How It Worked

A typical deck project begins by digging the holes for the footings, getting them inspected, then placing the concrete. We tweaked this sequence by putting the forms in place on day one. We then continued with our framing by supporting the beam with the temporary braces shown in the drawing. The posts were measured, cut to fit, and hung from the beam with the base and cap hardware already attached.

Using this method, we framed the entire 12-ft.-sq. deck on day one. On day two, we got our footing inspection, poured the concrete piers with quick-set concrete, and installed the decking and railing. We were done in two long days.

— Brian Brophy; Lockeford, CA

From Fine Homebuilding #218

RELATED STORIES

Got a Tip?

Do you have any great tips like this one on how to make temporary beam support for deck-building? Share your methods, tricks, and jigs with other readers. Tag them @FineHomebuilding on social, email them to us at [email protected], or upload them to FineHomebuilding.com/reader-tips. We’ll pay for any we publish.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Cepco BoWrench Decking Tool

Jigsaw

4-Gallon Piston Backpack Sprayer

View Comments

1 of the posts supporting the roof over my patio was severely rotted and needed replaceing. I used the hang the post method I had perfected some 27 years ago. some 27 years ago. (read about it in my soon to be presented book). I had purchased a handyman special. the first winter we has ice forming on the inside corner of the living room. to make the story shorter . the corner post was rotted someone left an hole in the lower roof. basically I made a support so the framing would not move and had the local machine shop manufacture a baseplate with a stud and hung the corner post. read more soon

I hope user-7047977 runs his book manuscript through a spelling and grammar correction program.