Decking is essentially flooring so why not install it using a pneumatic flooring nailer? You can now with the HIDfast decking tool and fasteners. I’ve been working with the HIDfast system for about a year now and would be lost without it. It’s faster than any of the other hidden deck fastening systems I’ve used; I can lay 100 sq ft of 5/4 x 6 decking in 10 min. to 15 min. The fasteners hold deck boards securely by diagonally nailing through one edge of the board in the same way a flooring nailer does, and pinning the edge of the oncoming board. And the fasteners are inconspicuous between the boards.

The HIDfast tool is pricey, about $430 to $500, which may dissuade some users; but many building material dealers are loaning the tool (or renting for a nominal fee) when you buy fasteners and decking from them. The fasteners run about $1.10 to $1.25 per square foot when laying 6 inch decking on joists set at 16 on center. This is comparable to other hidden fasteners on cost, but when the labor savings is factored in, the system is much less expensive in my estimation.

HIDfast seems to be reaching critical mass having recently partnered with Azek. Now when you click on the Azek Deck installation link, you land on a series of HIDfast videos. And after building a couple of Azek decks, I found them a perfect match. The HIDfast system is also reaching building material dealers through Azek’s distribution channels. So even if you haven’t seen the HIDfast system available locally yet, you probably will in the near future.

So how fast is it really? That depends on how complicated the deck is. On a rectangular deck with boards perpendicular to the joists and no butt joints, you can probably lay 100 sq feet in less than 10 minutes after a little practice. On a recent deck with jogs, diagonal corners and a butt joint in every course, it took about 15 to 20 minutes per 100 square feet – still a respectable pace.

Fasteners

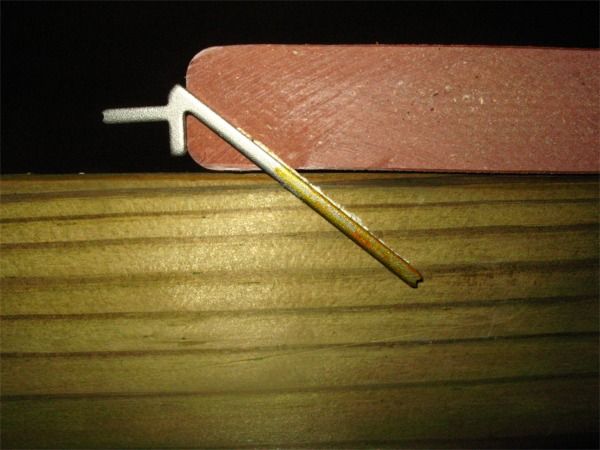

The HIDfast stainless steel fasteners have a unique design. The primary shank drives diagonally through the board and into the deck joist much the same way a flooring cleat goes through T&G flooring. At the head there’s a drop leg that automatically spaces boards 1/8 in. or ¼ in. depending on model. A spur sticks straight out from the drop leg to engage the oncoming deck board. After driving fasteners through the decking into each joist, you can use the dead-blow mallet (included) or a deck board tool to push or pull the next decking board onto the spurs. I’ve had best luck with the TigerJaw from TigerClaw and the PowerHand from HetraWorks mainly because both allow you to operate from a standing position. Some people who haven’t used the HIDfast system express concern about how securely the cleats hold deck boards down. I recently had to remove a board during installation that was upside down; my 16 inch flat bar didn’t have enough leverage to lift the deck board off the 11 joists it was nailed down to. Many other hidden fastener systems would have snapped right up.

There are currently four HIDfast fastener models: HF2.5 fasteners are used on 1 in. thick decking or thinner and HF3 fasteners on decking up to 1 ½ in. Both space boards 1/8 in. apart and are shiny stainless colored. The HF2.5WG and HF3W fasteners have ¼ in. spacer legs and are coated with black oxide to make them less noticeable between boards.

The Tool and Operation

The tool is a slightly modified flooring nailer with a special base and magazine designed to drive the stainless steel fasteners. A retractable stop pin registers the joist side so the nailer drives the fasteners dead-center on each joist. The pin can be inserted to the left or right side of the driver so you can work left-to-right or right-to-left with the highest efficiency. The kit comes with a steel donut that you slide over the joist stop pin when installing decking at a 45 degree angle to the joists. The donut spaces the driver so the fastener hits the meat of the joist. Just remember to always keep the shoe stop flat against the deck board – don’t angle the tool to the board.

There’s an accessory attachment to use when you’re installing pre-grooved decking. The attachment mounts to the back of the tool and registers the level of the fastener precisely off the joist surface rather than the top of the decking. By adjusting the attachment up or down, you can fire fasteners with the spur at the precise height off the joists to match the groove height on the deck boards. You’ll need this when installing dense composite decking and hardwoods to save the difficulty driving the oncoming decking onto the fastener spurs. I leave the accessory attachment on my HIDfast tool and don’t find it interferes with standard operation.

The HIDfast system works great with square-edged plastic and softwood decking. Many wood-plastic composite deckings have become denser over the past few years and work best when grooved to simplify engaging the board to the fastener spur. Same goes for hardwood decking like Ipe, Garapa, Cumaru, Tigerwood, and meranti.

Like any tool, it takes a little while to learn the tricks to be efficient and effective. Here are a few things I picked up:

Always make sure the shoe base is flat on the deck board before striking. Until you get used to the tool, use your foot to step on the base to make sure it’s flat. And don’t crowd the boards on the joists in front of you especially if you have the accessory attachment mounted on the back. If the attachment rides up on a loose piece of decking, it throws off the fastener entry point.

Watch the HIDfast video on how to install the fasteners on a joist where a butt joint occurs. Alternatively, you can scab one or two 2x blocks where the decking butt occurs.

Carry a ½ x 1x 4 in piece of metal in your pouch to use as a fastener set; occasionally when the fastener hits a dense knot in the joist, it doesn’t seat the fastener into the deck board so you have to help it along. A regular nail set doesn’t work as well as a square edged chuck of steel.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Reliable Crimp Connectors

8067 All-Weather Flashing Tape

Affordable IR Camera

View Comments

Azek? Who installs Azak? PVC is toxic plastic. I hope you're not breathing the stuff.

Mike,I first came across the Hidfast at Deck Expo last year.

Glen Tebo caught my attention in the manner that he was installing decking at a very rapid pace, took in the demonstration, still not convinced and kept walking. As I walked away, out of the corner of my eye, I saw 3 or 4 fellows with some thermally modified pine decking in the middle of the aisle. They took the Hidfast tool from Glen and they had a section of deck approx. 6x8 completed in no more than 2 minutes. I have to be honest, that got my attention. Made my way back to the booth and started chatting with Glen about his product.

By the end of the show, I was taking one back with me to Toronto with the help of my friends from Deck Masters of Canada Building Supply.

The deck we were building was an 800 sq.ft project.

Our clients were gracious enough to be our guinea pigs, and as far as I know we were the first to use the Hidfast in Toronto Canada. I have to be honest it was a little nerve racking using a non proven system on such a large job. I am happy to say that the job was an enormous success. The tool itself was very easy to use and the appearance of the deck is quite exceptional, not to mention less wear and tear of the knees. You can view our project at http://www.deckbuilder.ca