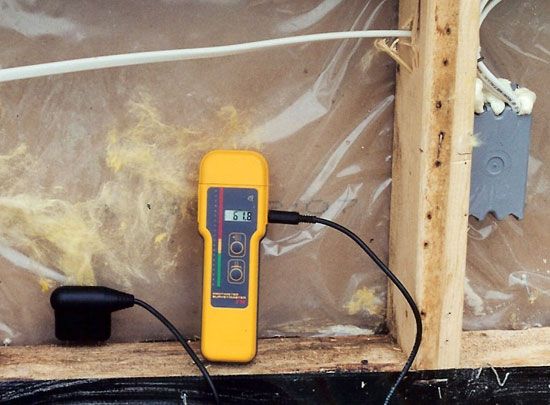

Poly sheeting installed behind drywall has been linked to mold and rot in numerous homes across the country. So why is it still popular with many builders and architects?

Over time, the use of polyethylene vapor barriers has been challenged by many building scientists. Yet some builders still use them, and some architects still believe they are appropriate.

Further Resources

Vapor Barriers vs. Vapor Retarders

Houses Need to Breathe … Right?

Tight houses and moisture problems

Stephen Thompson is one of them. In a post to the Q&A forum at GreenBuildingAdvisor, the architect says 10 years of work in Minnesota has convinced him a poly vapor barrier is necessary. He also points out that experts conducting seminars at AIA conventions insist vapor barriers are “essential in cold climates.”

Thompson’s claims rekindles an old debate on whether poly vapor barriers are a help or hindrance, and whether the real danger to buidlings are air leaks, not vapor diffusion. The conversation is the focus of this week’s Q&A Spotlight.

Read the whole article at Green Building Advisor.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

8067 All-Weather Flashing Tape

Reliable Crimp Connectors

Affordable IR Camera

View Comments

I know that they are dangerous here in the Tennessee Valley. I haven't seen them alot, but particularly some high end condos built in the mid or late eighties had a poly vapor barrier in the bathrooms connected to the exterior. Mildew everywhere. The wall perpendicular to it with the toilet and sink plumbing had no vapor barrier and no mold and mildew. I'm not saying just a little, I'm saying from one corner of the bathroom to the other. Homeowner had me bleach it, busting out the brick was not an option. I told him the vapor barrier was the culprit. He didn't believe me until he asked another builder. The new bathroom didn't get one.

I have my doubts about carrying sealing to an extreme. Older designs had a fair amount of 'leakage,' but I can't say that's a bad thing.

Think about it: moisture WILL enter. Sources are many: condensation, brought in with the building materials themselves, and as a by-product of chemicals curing. Once in, where will it go? I can recall one poorly made 'shower seat' that held a good 6" of pond scum within the well-sealed base.

For me, the 'lightbulb' went on when I had to address the damage a very minor basement flood caused. I went through several models before I realized that most of the advice out there is simply wrong.

That's why I think that 'making a perfect seal' is the wrong approach.

I refuse to use a poly vapor barrier even if it would be specd. Thirty years ago I gutted my old farm house and thought I was doing a good thing, I placed poly barrier on the first floor. Even our clothes and shoes that were temporarily stored on racks next to outside walls became extremely moldy.

I saw a builder tear poly off the whole house after a homeowner spent the whole weekend stapling it on. Another homeowner called me to check some roof repairs, as it turned out the condensation formed under the poly soaked the drywall till it was dripping. Sometimes less is more.

There's a very simple solution folks....build with Structural Insulated Panels. No air flow through the wall or roof assembly, no condensation. Use an HRV system to control interior humidity levels and assure air quality.

William Rose's book "Water in Buildings" is a real eye-opener on this topic. Also, having become a Passive House Consultant, I've learned more about building physics; between these, I've concluded that in our cold climate (Chicago), a poly vapor retarder is bad unless it's airtight--and guess what--it's almost impossible to get airtight! So all i does is trap moisture in the wall. Instead I prefer an interior air barrier using OSB (often with SIPs), with joints taped with SIGA tape, and mechanicals run in a furred wall in front. That way moist air isn't getting into the assembly from the inside except by diffusion--which is a tiny amount--and that amount can dry to the inside OR outside if I use high-perm sheathing and wrap. I'm sure this assembly would need to be adjusted in the south (warm-humid) where the moisture drive is as much or more from the exterior than interior.

Reno, the argument for leaky buildings is weak: random leaks carrying moisture will condense and cause structural damage, mold, etc. Make it airtight and use heat recovery ventilation and you'll have a lasting structure. But you have to be sure that the assemblies can dry to inside or out (basements need to dry to the inside). 20+ years of passive houses in Europe have proven this point.