A recent blog post asking readers to weigh in on the merits and utility of their corded drills has sparked an interesting topic:

Are today’s power tools junk compared to the power tools used by our fathers and grandfathers?

I can see the argument being fiercely debated by both sides.

On the one hand, we have modern cordless tools at our disposal that rival the power of their corded counterparts – an absolute revolution compared to being 100% reliant on extension cords in the past. There have also been huge advances in electronic-controls, keyless chucks, accurate fences, and let’s face it, today’s tools are a heck of a lot lighter and more comfortable to use than many of their predecessors.

On the other side of the argument, many people believe that today’s tools are basically throw-aways. Metal has largely been replaced by plastic. Power has often been dialed back in the name of better control, and replacement parts? Good luck even trying to back out the screws holding the tool together.

The proof is in the history…

- Skilsaws that could plow through miles of wet PT lumber and then scoff at you for being tired at the end of the workday.

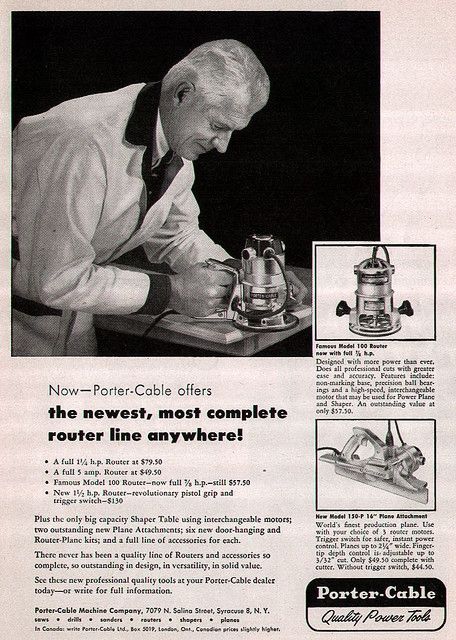

- Metal-cased Porter Cable routers that could survive a skydiving accident, nevermind an accidental drop from a countertop.

- Milwaukee Sawzalls being used in the most heinous of situations, breathing in dirt, dust, and embedded nails, spitting out nothing but smoke and wood chips.

…nowadays a cut-cord is enough to toss the whole tool. A dead battery means an upgrade instead of a replacement pack. Heck, pros are now buying DIY entry-level tools from Ryobi, Craftsman, Skil, and others (many of which used to be the premium brands, by the way) and say “hey, if it lasts me 2 months I still got my money’s worth.”

Will Bosch’s portable table saw — widely argued to be the best in the market — outlast the old Makita models that EVERYbody used years ago? What about the classic Hitachi miter saw? It was innovative, and is still the top choice for many carpenters for it’s small size and comparitively huge capacity.

So where do we stand? Are modern tools just throw-aways?

Hopefully all of you tool developers, makers, and product managers reading this blog (and I KNOW you’re reading this blog!) will chime in with your stance.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

8067 All-Weather Flashing Tape

Handy Heat Gun

Affordable IR Camera

View Comments

The main reason manufacturers produce "throw-away" tools is that we buy them. If we didn’t—they wouldn’t.

But I don’t have a problem with manufactures making inexpensive tools available for the hobbyist; if the price is right. I’m a hobbyist myself and not a working professional these days and should probably be buying more throw-aways because I rarely have a chance to give new tools a proper workout before the 90-day or one-year warranty expires.

I’m a proud tool junkie. Cheap tools that look like they should have "Made by Mattel" stamped on them make my skin crawl. So now I’m buying Festool, Fein, etc.; so that I’ll have something to pass on to my children.

I hold a neutral stance. Sure there are tablesaw's, drills, skilsaws and pneumatic tools built in the 60's still holding strong today and yet some saws and drills built today break down in a few months. Keep in mind though that today, we have guards on our saws, we even have a tablesaw with flesh sensing technology built in, and our drills don't have trigger guards on them (which breaks a finger ever so easily).

I love my cordless impact driver and drill. Most of us forget that some of the first cordless tool's where just like toys and yet most contractors and subs I work with today use a cordless drill or driver daily.

This is certainly a give and take issue. Modern tools aren't junk but they certainly are not built to the same standards as their precursors. However, those vintage tools need not be put on a pedestal. They were heavy, inconvenient to use, often lacked safety features, and did I mention they were heavy. Also, weren't tools back then quite expensive compared to today?

While I'm too young to know (i'm 31) I have been told that tools used to be much more of an investment back then, now tools are cheap enough to just be bought on a lark. Personally I have 9 drills, 6 routers, 3 circular saws, 3 miter saws, and 2 table saws. There's no way I could afford such luxury back in the 60's. On the other hand, I don't plan on "handing down" my tools, at least I don't buy them with that intention. When I started out, I had a few tools handed down to me - I recall the giddy nostalgic stories that accompanied each tool. But to me those tools were junk compared to what I wanted and subsequently replaced those hand-me-downs with. One thing is for sure, nostalgia and sentiment make old stuff seem better. Personally I cannot imagine having sentiment over a tool.

That said, I think every tool manufacture makes lemons but most of them produce a gem or two. Just as Justin made his short list of standout tools; Skil Saws, Milwaukee Sawzalls, PC routers, Hitachi SCMS's, etc are only a few of many great tools some of which are still produced. I don't think you could ever have blindly purchased a tool and claimed it as the best. I put a lot of time and research into every tool purchase. I have the Bosch 4000TS but I didn't buy one for three years after their release so I could wait for any issues to shake out. When I am looking for the best, I try to ensure I am getting the best. Alternatively, when I wanted a framing planer I just bought the cheapest one that HomeDepot offered... Ryobi $40. Then I don't care if I drop it it gets kicked or falls off the roof. In fact, I fried out the belt in the first week but it already did the job it was purchased for and I just exchanged it for a new one. I guess what I am saying is that there are still plenty of quality tools out there but sometimes we just need a junk tool.

DC

My tools tend to break before they wear out. It's usually cheeper to repalace them than repair them. Seems kinda counterintuitive.

For some reason when I am using the old power tools I get the feeling that I am more in touch with my past. My Dad used some of these tools, these tools were made in the USA, they were made to outlast their users. They fairly scream integrity and I get the impression my work is better when I use them. Certainly my attitude is better.

@jdr86

You're obviously not using them every day then.

What do you do for a living? Maybe you work on a computer... try using your dad's computer every day for work. ;D

DC

I don't think that they were necessarily intentionally made to last decades. Metal and rubber were really the only materials they had to make tools with back then.

I'm in the middle here too. I've got an old router that weighs 20 pounds by craftsman. I had an old siding nailer but replaced it with the newer model yesterday. I actually used them both today. The older one was heavier so less recoil. It seemed to feed the coils a little better, it didn't skip as much. The new one was two pounds lighter. It seemed to use the air a little more efficiently. Its depth adjustment was better. Did I mention it was lighter? Either tool could have done the job.

I still have my late grandfathers handplane, though. I find myself reaching for that thing more and more lately.

Dream weaver,

No I don't use them every day. The old tools would certainly stand up to it though. What kind of work do you use your tools for now dreamy?

@jdr86

Thanks for hacking up my screen name, that says a lot about you. If you were to have clicked my name in either of my comments you would've been taken to my profile where you would learn that I own and operate Dreamcatcher Design+Build.

I rely on my tools as a means of income and take the discourse of tools more serious than most. I choose the tools my crews and I use daily (from app to adze) and I am the one usually performing repairs on our tools - often on my own time. So choosing the most reliable tools is even more essential to me.

Also important to me is not destroying my body during my lifetime. I have already taken hard hit due to the dinosaurs of power equipment that my previous employers forced me to use. We are talking 17 pound routers and 9 pound nail guns - if a nail gun at all. I wished those tools could have died many years before my employment.

So, now I advocate better new tools rather than nostalgia over old tools. If one wants to use his grandfather's old handplane, fine. But if his grandfather was a cheapskate, like many men were back then were, that handplane might be a POS compared to what you can get from Lee Valley these days. On a different line, it may be smarter to learn how to use a router like a hand plane or try a power plane. I guess the point is - just because it's old (and may have been touched by someone you love and respect) doesn't make it better. I don't think there is debate in that. Being better makes it better - lots to debate there though.

DC

I think modern tools for the most part are better. One thing I have noticed is how some companies are giving lifetime warranties while their tools are built with cheaper parts. I think they can do this because most of their tools sold out of the big box stores these days wind up being expensive garage decorations. I know guys that go through a compressor every year or so from Home Depot. They get replaced for free so they think they are getting a deal even with the unplanned trips to Home Depot. One masonry contractor I know went through 3 or 4 in one year. We had a Rigid compressor for a couple days. Took it back because it would creep across the floor on its own. Been running a Makita mac700 for 5 years now. There is a very big difference in the longevity of different tools in the same price range. It's all about marketing these days and the tool companies know this. We have to do homework. I always research every tool purchase on internet. Reviews on Amazon.com have been helpful. The problem I have with many tool tests is that they test tools head to head when brand new. This has little to do with how tools are doing after 1 or 2 years of heavy use.

I use many different tools on a daily basis and have for years. I find the "new" tools, meanig those bought over the last few years, look fine but are of lower quality inside, brand does not seem to matter. A Makita circular saw I bought in 1978 is still working, the one I bought a couple of years just like it, well it's long gone to the heaven of saws.

As I understand it, much of the tools and parts that make up the tools are now made in China, because to keep up with the low prices that "everyone" wants, manufacturers have to make them cheaper, so jobs are lost in north america, and then we don't have the money to buy the better stuff, so they have to make them cheaper, and the circle goes 'round and will keep going 'round until we are the cheap third world labor and the chinese are buying the good stuff because they have all the jobs, and we are dirt poor willing to do anything for enough to buy a bowl of rice.

As for the tools, the new ones ARE crap! Blame yourselves! .... at least if you keep buying the crap! Demand something better, Demand quality and be willing to pay for it, buy North American!

By the way... Just because it has a "lifetime "warranty does not make it better, when it spends all the time you want to use it at the repair shop waiting to be fixed, or waiting for a new battery to replace the one on warranty. Sorry rigid, it's gone limp!

Gadget,

You make some good points about pricing, and how it affects the tools. I've been talking to some of the major power tool companies and it seems that one of the issues is Home Depot and Lowe's having so much clout, that they can dictate pricing. In other words, they demand that the power tool maker create a circular saw with x, y, and z, and say that it has to sell for $xx - otherwise they won't put it on their shelves. Tool makers are forced to either comply or sell elsewhere.

There are a couple of tool companies on the brink right now...teetering on the edge of being run out of business by this strict buying/pricing structure.

Oh I also should add, quality doesn't necessarily mean that it has to come from the U.S. - companies like Festool and Fein have proven that German engineering and quality are very top notch. That's just one example.

There are some interesting forces at work in the marketplace, and this blog entry didn't even go far enough. It's not so much about Skil, it's about Harbor Freight. Now those tools are CHEAP. Literally, you can buy 10 of those tools for the price of 1 high quality one. These are mostly from China, I'm sure. Now at these prices, you literally are talking about throw-away commodities. Interestingly, I haven't had a Harbor Freight tool break on me yet, although it wouldn't surprise me at all. I bought a variable speed reversible 3/8" keyless chuck drill with trigger lock for $12. I couldn't sell the box and manual for $12 and make a profit. They also offer relatively cheap long warranties, which might or might not be a good deal as well.

This is stiff, stiff competition for the high quality market - 1 high quality tool, or take my chances with a cheapie and buy a few more if it breaks? Even if I have a top quality tool, why not buy a cheap backup or 2 just in case I need it on a job? Of course, if you need the power or precision or other feature of the high quality tool then you have no choice.

By the way, I absolutely appreciate top quality - I just can't afford it :-( And I do have a few old-time power tools that have lasted for decades and are still going strong. But that doesn't mean it makes good sense to buy tools that last 50 years now. As a part-time generic handyman home improvement person, I need a dizzying array of tools. Harbor Freight allows me to buy the ones I don't use often. If I were strictly a carpenter or tiler 40 hours a week, I could buy some top quality specialty tools I use every day. I wouldn't trade my 20 year old Makita cordless drill with original batteries still going strong. But I also wouldn't trade my Harbor Freight tile saw that I got on sale for $40 either! Nor my multi-tool that I got for $25. Both see occasional use, but are indispensable when I use them. And they can break 3 times each and I'll still come out ahead. Who knows, when it breaks I might have decided I want a different tool or different features next time.

When was it, that we as business owners and contractors agreed that cheap and disposable tools replace high quality and durable tools. That, it is alright to buy 5 cheap cordless drills within the same time period as one quality drill. I have used practically most tools from all the major names. I am not impressed with any of them. Except with Skilsaw worm drive. I have two of these and both are nearly 20 yrs old. One I use to cut though asphalt shingles, sheathing with nails with a dull blade and sparks shooting. It never dies. Try doing that with some pretty shinny saw today off the shelf, good luck. I am not impressed at all, They are geared to be mass produced, high profit for the manufacture, cheap enough so that when it does break down it is cheaper to buy a new one then it is to fix it. Why is it that it is cheaper to buy a new drill, charger, case and battery then it is to just buy a replacement battery. What a waste of resources. I would think that today, they can figure a way to make good quality, long durability, and at a affordable price. I do not need a saw with a flashlight, laser, tv and gps. I need a saw that will last and stands up to the use and sometimes abuse of a real life, in the field under real condition. Not some showcase TV show part time contractor. There is a sucker born every minute, and every time I purchase a new tool, I feel like I am that sucker. Because I know that within a year or so I will be tossing this tool in the trash.

In days past, tool companies took pride in what they sold. They were proud of how powerful their tools were and how long they last.

Many contractors that have been around awhile still have some old favorite tools that are still used regularly even though they are 20-30 years old. I do.

The foundation for the problem we see today are in the large soul-less corporation. "Good" tool manufacturers were bought out by large corporations and these large soul-less corporations are ONLY interested in making as much money as they can, as fast as they can. They have nothing invested in their "brand name". So they will trick the public into buying cheap "made in China" junk tools by putting a respectable name on them. But that cannot last forever, the idiots (us) buying the tools will eventually catch on....

We are a GC and we constantly buy new tools due to growth and expansion of offerings.

When we order/buy new tools we first look at the sticker on the tool to see where it was made. If it says "China" on the tool, it is shipped back, period. We will absolutely not accept it.

We have found that you cannot rely on the manufacturers honesty for your answers, only a hands-on inspection will get you the info you need.

We recently purchased a DeWalt HD gas air compressor for $960 that they claimed was made in USA on their website. I also emailed their CS dept to verify the country of manufacture.

They lied. Most parts were tagged "made in China". The box said "Final assembly in USA". Nothing that I could see was made in USA. We sent it back.

The brand names today are almost meaningless. The only issue is where they are made.

Made in USA, great.

Made in Germany, great.

Made in Japan, usually great, but not always.

Made in Mexico, not sure about that, but it is a far cry better than made in China.

We recently had to buy several Bostitch nail guns and the new guns were all made in China. We searched around and found old stock on a shelf that had been made in USA and bought them. But that solution will not work for long.

We used to be proud to own & use American tool brands, but not anymore.

Millions and millions of jobs have gone to China.

Let’s add it up: 20-30% unemployment, companies cut back everywhere, banks will not make loans, housing prices took a dump, investments are down, foreclosures are off the charts and our government has spent us into oblivion.

How many homeowners are absolutely certain that they will never lose their home? How many of those homeowners will invest in their home even knowing that the value will most likely go down?

How many are left that are willing to pay us to do what we do?

Most RFQs we see now are based solely on price. In the past this was around 20% of the RFQs we saw; now it is 80-90%. The customer doesn't want to spend any more than absolutely necessary.

I am not saying that the American tool companies that now manufacture in China caused the problems with our economy. But I AM saying that this issue IS part of the problem.

How much better would your local economy be if there were a few hundred thousand tool manufacturing jobs added in your state?

We will continue to purchase only tools and materials made in USA. At least that way, WE are not part of the problem.

Dan

I wish the battry's for cordles tools would last longer.

I have a Makita drill that came with 2 batteries and altho I had it 3 years I had to buy a battery for it three times

so far and they are costly $50.00 each.

Maybe I am not recharging them properly or doing somthing wrong. Can or should they be left on charger till needed?

I do like the drill and I do have drills with power cords that are allways availlable.

If anyone has any suggestions Iwould greatly appreciate some help. I also have a Dewalt screw driver & three dead batteries.

Thank you for any anticipated help

I don't think the good old days had any lock on quality tools. I'm sure there were as many cheap throw-aways then as there are now, proportionally, it's just that the good tools survived longer. And despite the abundance of plastic these days, the current batch of tools are, for the most part, better engineered for weight, safety, and ergonomics. Yes, those old shiny PC routers would still work after getting hit by a truck, but the power cords weren't grounded (the chassis weren't shielded either, I don't think), and you had to use two wrenches to change a bit. And if my two Stanley (yes, that Stanley) routers are any indication, the brushes and armature bearings weren't that great either. Caveat emptor is always a good rule to carry into the tool store.

No the new tools aren’t junk, at least not the ones that I buy. The new tools are great. I don’t miss those old heavy duty corded tools, with extension cords running all over the place.

But I do miss one, the little 1/4 inch drill motor that I just loved for its size mainly, that I had years ago. Beautiful little tool. Then they started making the 3/8 inch jobs, then 1/2 inch…just like the routers, bigger and bigger. That little 1/4 inch drill motor would be great for bench work still today … but maybe a smaller cordless with a keyless chuck would do better?

I gotta agree with ChuckB...there is and has always been some diamonds and some real piles of garbage. You just have to look at things in context.

Like, sure that old SkilSaw was great. But how about that Kut-King saw? Don't remember that one do you? That's because it was a pile of garbage.

Or How about my grandpas 1968 DeWalt "Power Shop" radial arm saw (made by Black and Decker) they sold literally millions of those things. But compared to my 1951 DeWalt GW (made by DeWalt) that Power Shop was a pile of garbage.

Or take a 1955 Delta/Rockwell jointer - a stout and well loved machine, probably the envy of most woodworkers. Then compare that to my 1915 C.O.Porter jointer and the Delta looks like a flimsy pile of garbage.

On the other hand, look at ANY Delta Unisaw through the ages and compare it to the all new Unisaw. Are you really telling me that you'd rather have the old version? Or, would you like to compare a Delta Sawbuck to a Bosch Axial Glide? Maybe an original "Sabre Saw" to the current Bosch jigsaw. How about a swollen arm and a hammer compared to the wide variety of lightweight pneumatic tools that are available today?

Anyone who broadly labels the tools of today "junk" compared to the tools of yesterday doesn't really know jack about tools. There's plenty of great tools made in China and there's still plenty of junk made in the USA (and vise versa of course). The only unfortunate fact is that there is just too little of both currently being made in USA. The only reason I make an honest attempt to buy USA made is because literally ALL of my clients are Americans.

DC

An interesting point of reference, or perhaps a benchmark: One of the product guys from Festool once told me that they aim for every tool they make to last at least 10 years without repair, and I also read from another user that they guarantee the availability of replacement parts for 10 years after a tool is phased out/replaced by a newer model.

That's for some of the highest priced tools on the market. So where does that leave us with the mid-level tools? 3 years? Less? Some of you spoke about lifetime warrantees that don't amount to much...should Festool be the benchmark by which others are now measured?

Another interesting note is the on the prices of the tools pictured above.

I can't tell the exact dates or the prices on the routers but making an educated guess I would say the PC router ad is from about 1955, the Skil saw ad is about 1965, and the Shop-Vac ad is from maybe 1970 or so.

Using an online historical money converter shows that:

The $49.50 cost of the Skil saw is equivalent to $375 dollars today,

The $69.50 Shop-Vac would cost $396 today,

And the [hard to see] $79.54 PC router would be a whopping $657 dollars today!

Yet for today's equivalent to those same tools, the current prices are only about $20 more.

Maybe Justin can confirm the exact dates and prices in the ads, but I couldn't be too far off.

DC

The dates are certainly close enough to back up your point, Dreamcatcher. I'm not sure it's entirely valid when looked at only from a money calculator point of view. According to the history of national minimum wages, the pay in 1955 would have been roughly parallel to the pay today.

http://oregonstate.edu/instruct/anth484/minwage.html

As I put a little more thought into this subject (hey, I love talkin' tools) I realized that the problem is DIYers! Long ago, tool quality levels were quite easily distinguishable between DIY, Professional, and Industrial. But every DIY/hobbycraft boom in the past century has coincided with the cheapening of power tools. Because of that, professional level tools have reduced in quality to take advantage of cheaper production techniques used in the DIY tool makes; leading us to today where the line between industrial, professional, and DIY tools has blurred.

Are Craftsman tools professional level? Are Ryobi tools? Rigid? Festool?

I think many would say Festool is professional level but I am not so convinced. I think their main customer base is wealthy hobbyists and in such their claims of higher durability and accuracy are invalid since the tools are used so infrequently and protected much more than, say a Skill saw would be.

To me, some examples of truly professional level tool companies are Metabo, Mafell, and maybe Flex. Unfortunately the N.American tool offering from these companies is currently limited and their advertising isn't at all aggressive - likely because they aren't gunning for the DIY crowd like Festool and Fein.

But I think with the conglomeration of yesteryear's tools combined with a slump in the DIY market it may be ushering in better professional level tools. Bosch seems to be trying to re-distinguish itself as pro-grade, Delta has new ownership and has some great new offerings, and Flex has began it's N.American campaign (albeit only in the concrete/stone market for now).

So, the professional tool market may be looking up so long as we don't expect to see that higher quality from the old players like Milwaukee, Porter Cable, and Hitachi and are still willing to pay top dollar for quality. Also, we may need to rethink where we buy our tools. Boxes don't carry the quality goods, neither do most tool stores yet, an lumberyards are all but extinct - online buying may be the only way to get the good stuff.

DC

Since we are on the subject of tools. Let me ask, what sawsall would you recommend. Forget Delta, Milwaukee, or Porta-cable. Been there done those. I was thinking Bosch, but I had one awhile back and it self destructed in my hands. I would like 1 1/8" stroke all balls out take no prisoners saw. What is your experience, I don't need an advertisement.

@amazingrace

Well you ruled out about half of the viable options out there. Depending on what you use it for to require "all balls" and "no prisoners" you may want to look into an electric chainsaw like those offered by Makita. I don't have any experience with them but I have heard some about Hilti's reciprocating saw. Personally I have owned the same PC Tigersaw for the past 13 years and been totally happy with it. I used a Hitachi once that had an extremely aggressive orbital action that seemed to cut wood very fast - it had good ergonomics too - but I can't vouch for it's overall durability nor do I know if they even still make that model. I have used several models of Milwaukee Sawzalls through the years, all of which seemed the same to me and got the job done. I know Milwaukee fans swear by them.

Again, it may depend on what you do. Chainsaws are best for clean wood. I like to demo roofs (shingles/sheathing/nails/drip) with a Mil worm, I chop sheathing out of window openings with a Bosch Colt, I cut pipe and angle iron with a Mil band saw, and I cut heavy iron with a torch. Some tasks are better suited for a Sharptooth Saw.

Hope that helps some.

DC

Amazingrace,

I'll be straight with you, we haven't tested recip saws in a few years, so I can't speak with much authority about which is the current top model. I know I've had some trouble, and others have as well, with Bosch's blade release system getting stuck.

when you say about the other tools "been there, done that" does that mean you've had problems and are looking for other options?

I am a carpenter, been in the field since the late seventies. Started working with my uncle and then started my own contracting business. Most of my work is renovations with of course demo. I work in all ages of homes spanning from the 1900's to present day. The older homes consist of true 2x4 with 16d nails and with the steel frame, steel casing windows and doors. I have used the previous mentioned recip saws and they fail all to early. From triggers not working, blade clamp getting stuck open or close, shaft snapping. I do not expect the thing to last forever, but give me some satisfaction. For example, I mentioned the Skil worm. This saw just does not want to die. I have cut miles of roof and lumber, left it out in the rain, rolled of the roof. And it works every time I pull the trigger. I can not say that with the typical recip saw. Right now I have three Milwaukees, and from experience I know that two are about a year old and will soon be failing for one reason or another.

I am just saying, that if they are constructing a tool for a specific task, then make it so that it will work hard, stand up to the use that it is going to encounter. The previous blog mentioned that the line between homeowner grade and contractor grade is blurred. I look forward to the day when there is a distinction between the two. Would it be acceptable if the bathroom I remodeled falls apart in three years? I do not think so.

What I mean by, balls out, It simply means that if I am using a recip saw with a 10" blade, bi metal, full speed, cutting though a 1920's steel casement window. The only metal I want to see is the frame being eaten and spit out by this saw. Not smoke, sparks and gear pieces coming out of my saw. Yes, I am looking for options, maybe something I have seen on the tool rack but did not want to take a chance, I do not know, surprise me, I am all ears. Thanks for the reply!!

While some older power tools were beefy and made of steel, they did not come close to the usability of today's tools. Put it this way, if you set a tool from 1960 next to its current day counterpart, which would you pick up for a days work?

Part of that convenience and ease of use is a lighter weight. Well, they haven't figured out how to make steel lighter, and how many of you would pay for titanium cased tools with Ti components? So we get plastic that is very nice to use with innovative safety and convenience features.

As for recip saws... I love my Makita corded. It is a beast and has been going strong for 4 years.

The only tools I use regularly that are "vintage' are my collection of Craftmens halfHP routers. All three have builtin lights so I can see as I work. However, my favorite router was an old RAM (circa 1960s) thats relative to todays trim routers in size and power. Unfortunatly it gave up the ghost last summer. With mainatence, replacing brushes, bushing/bearings over the years these tools will last many more years but the cost of components is such now that it's cheaper to buy a modern counterpart and be done with it.

There are many great points made in the March comments. I would say they pretty much covered the waterfront. Coming from a family with a building trades history gives me the perspective that I will not buy the least expensive tool. That "wisdom" was not "passed down" from generation to generation by word of mouth, however. It was simply a response to economic sense when you're looking at 3 garbage cans full of burned out "cheap" tools.

Those cheap tools had been purchased when I was young and thought I couldn't afford the "Good" tools. When you ask yourself how many times am I going to buy a circular saw, or drill, etc, the "wisdom" becomes you can't afford not to buy the "good" ones. That's not to say that money is the only variable, quality is high on my list because quality tools feel better underhand and perform better in most tough situations. You smile when you pick up a quality tool instead of grimacing when you pick up a poor quality tool.

Sr_Inspector made a ton comments that were right on IMO. Successful good tool companies in the old days were usually started & run by engineering/mechanical oriented folks and their focus was quality, not price. As time passed, the bean counters and marketing gurus became infected with the "more, more, more" attitude that was fueled by Wall Street's "Greed is Good" approach.

It was the rise of the smart cookie CEO's who were driven by greed that led to the the downfall of quality, the outsourcing of jobs, & getting in bed with China. Being "smart" cookies, their only focus was cost reduction (how else ya gonna make stock price & your pay go up?) and their primary marketing thrust was to ride on the reputation of quality in years past, hoping they'll be long gone before the cat gets out of the bag.

The chickens are beginning to come home to roost. I bought Milwaukee Electric Tools for a long time (mine are all US built) because they were good at that time and all of my 20 to 30+ year old Milwaukee tools still run just as well as when they were new. Once I found out the entire company had been sold to the Chinese, I haven't bought any since. They go to great lengths to hide the fact that they are now a Chinese company and the lion's share of their products are made in China.

So, what happens when you take a country that is finally going through their own industrial revolution? China has been a poor agrarian society for a very long time. Well over 90% of the labor force are or were farmers and are not well educated. These are the majority of workers now staffing the new factories; inexperienced & under educated. They are the weakest link in China's manufacturing chain. Buyer beware.

Loved my Milwaukee 18v Lithium hammer drill along with the other tools that came in one of their kits. Well that light powerful drill died after I covered a 20'x 24' pole building with steel. Milwaukee said "burnt/melted motor from overloading" - apparently it wasn't designed to drive sharp 1 1/2" screws for a few hours each day. Sad commentary on a once solid name. I saw a Milwaukee truck outside Home Depot one day and tracked the salesman down in the store. He was wearing a Rigid Tools shirt while checking Ryobi stock. Perhaps the conglomeration of tool companies is a bad idea.

The thing is, almost everything you buy these days is crap, a bitter disappointment the result of most significant purchases. Is this the result of greedy corporations screwing their consumers? When will business realize that the relationship between the manufacturer and the purchaser must benefit both parties? I'll give Milwaukee a hint when I don't buy any more of their tools!

After reading all the comments in this thread, the one issue that I have not heard mentioned has to do with ease of use. Cost, country of origin and longevity are all valid points but what about how well a tool works and how easy it is on the operator? Some jobs are no fun to do in the first place but when you combine that with fighting a tool, it stinks.

I bought a Sears router for my father for a Christmas present 40 years ago. And, when my dad past on I got all his tools. I still have that router & I still use it a lot & it is still going strong. I only had to take it completely apart one time to clean out the sawdust since all that time. I have a fair amount of Sears tools that I bought long ago. But, now it seems like I buy other brands as well. I try to get value for the buck. But I still settle for QUALITY before I buy a tool. But, to each their own is what I always say.

My comment to those who trash Chinese goods: some of the best, most desirable products in the world are made in China, like iPhone and ThinkPad laptops. China's bad rep comes from American CEO's dictating how much a tool is going to cost to the Chinese factories. The manufacturers then have to cut corners to hit the cost target. Don't blame the Chinese, they're just building to specifications.

While we're making some really good points AND doing a little b****ching, I vote that we all give our tool-buying dollars to the company that makes a truly rugged case with room enough for the cord, bits, blades, etc, as well as the tool. Those blow-molded plastic things become an unsolvable puzzle after a few uses.