The Attach-A-Deck is a simple deck ledger mounting system that stands the ledger off the wall eliminating the need for flashing – that’s the big benefit but there are other features I like. Attach-A-Deck can be used to mount ledgers on new homes and retrofit decks over siding on existing homes, the system is tested by an engineering service, the installation is simple and fast, lag screws can be used (something the 2009 prescriptive ledger mounting table only permits for bolted ledgers), and it’s reasonably priced.

A lot of deck builders like to space ledgers off the wall so water doesn’t get trapped and leak into the floor framing system. The conventional way to do this is with stacks of washers, plastic spacers or wood blocks. Attach-A-Deck engineers the space into the attachment device and provides a fastening schedule based on the depth of a deck.

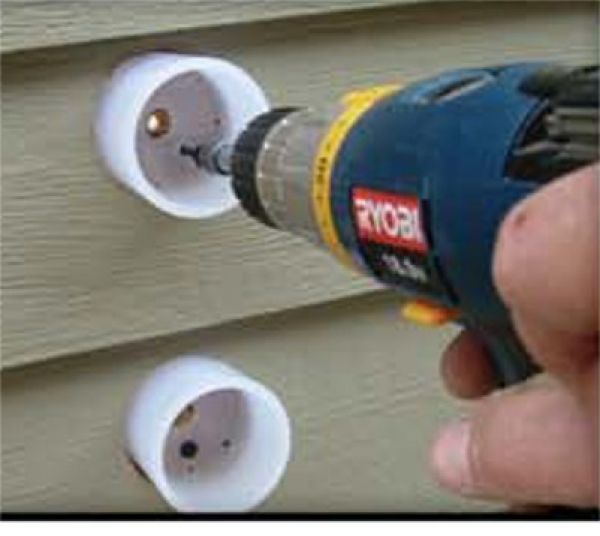

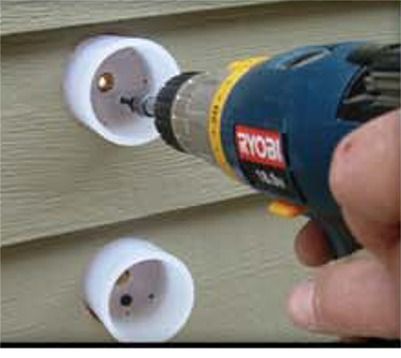

Attach-A-Deck works great for mounting a ledger over existing siding. You just drill 2 1/2 in. holes through the siding to the face of the sheathing, apply the Attach-A-Deck fasteners and mount the ledger to the house. Conventional spacing systems are limited to ½ in. by code, but ½ in. isn’t deep enough to accommodate siding thickness. And since siding is not a structural part of the wall, we can’t bear the ledger against it. Attach-A-Deck spacers are 2 in. deep so they can handle siding up to 1 1/2 in. thick and still leave ½ in. air space.

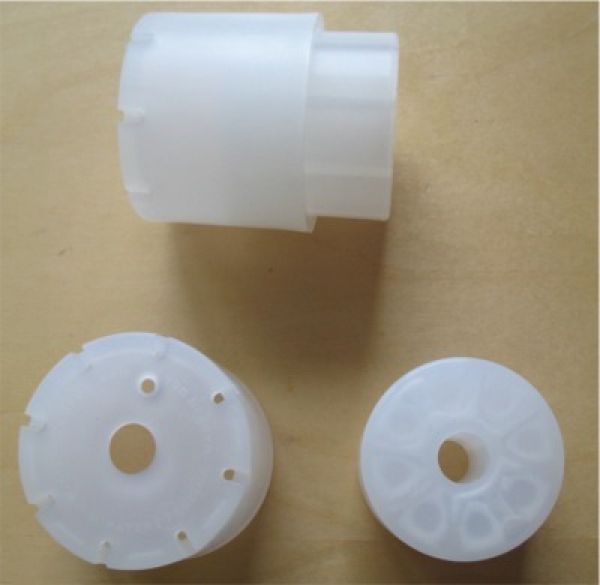

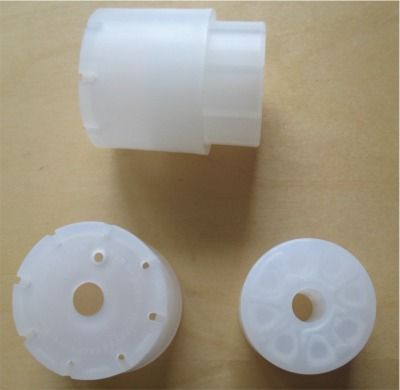

The ‘plunger and cup’ design back-caulks and seals the siding hole filling in the gaps from the inside – out. This is accomplished by filling the Attach-A-Deck cups with sealant before screwing or bolting the ledger onto the wall. The plug part of the system works like a plunger in each cup and forces sealant out of the series of holes around the perimeter of the cup. As you draw up the ledger fasteners, sealant is forced through the holes to seal the perimeter – it’s ingenious.

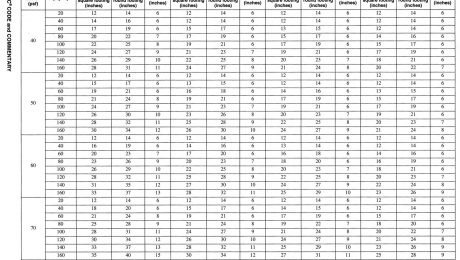

Attach-A-Deck can be mounted with ½ in lag screws or ½ in. bolts. It’s the only ledger mounting and spacing system that I know of that can be mounted with lag screws. This is handy when you don’t have access to the inside of the house rim joist to install bolts. And the system is tested for use mounting to both LVL and strand type engineered rim board; something the IRC doesn’t permit when using the prescriptive code table. Attachment schedules are for deck loads of 60, 70 and 80 lbs/sf and based on joist spans from 6 ft. up to 16 feet. Since the total load for decks is typically 50 lbs/sf (10 dead, 40 live), the additional loads can account for snow loads or locally enforced live loads. The devices are installed in pairs spaced 2 in. down from the top and up from the bottom of the ledger. There are good diagrams on the Attach-A-Deck website suitable as submittals.

Attach-A-Deck does not have an ICC-ES Report so you’ll want to check with your local building official before using them. Washington State University’s Wood Materials and Engineering Lab tested Attach-A-Deck. The report is available on the Attach-A-Deck website for submission to local building officials in lieu of an ICC-ESR. I’ve spoken with the inventor, Jeff Johnson, on several occasions. He’s happy to talk with local building officials if you want to use the system but run into resistance.

There’s a short learning curve to installing Attach-A-Deck. I find using the ledger as the drilling template to be the easiest technique; it’s described on the website. Essentially you mark out the deck joist positions on the ledger, locate the Attach-A-Deck spacers so they won’t interfere with the joists or hanger flanges, tack screw the ledger to the wall, and bore pilot holes through the ledger and just a little into the siding. Lower the ledger out of the way and drill holes through the siding for the cups. After you mount the cup portions to the wall and fill them ¼ to ½ way

with sealant, insert the plugs into the cups. Slide a couple of lags through pilot holes at each end of the ledger to serve as orientation dowels and then lift and orient the lags to the Attach-A-Deck centers with a helper.

I like to screw the lags into the wall about ½ in. at a pass starting at one end of the ledger and working the way down. This sequence draws the ledger to the wall in two or three passes allowing the sealant a chance to squeeze out in stages. You’ll be able to see the progress as you sock the screws down on the last pass; the sealant will ooze out between the edges of the cups and the siding. Once the rim of the cup seats to the back of the ledger, you’re done tightening.

The process for mounting the with bolts is similar with the main difference being you bore the pilot hole all the way through the rim board of the house and insert the bolts from the inside so the nuts end up on the ledger side of the assembly. I slide the cups onto the bolts, fill them 1/4 to ½ way up with sealant and then slide the plugs on. The bolts need to be an inch or two longer than the distance from back of rim joist to face of the ledger to account for the sealant-filled cup; I usually use 7 in. to 8 in. bolts depending on the thickness of the rim board and sheathing. Don’t bother trying to hand-press the ledger to the wall to account for short bolts – you need the pressure from the nuts to force the sealant out into the joint.

The sealant is a critical element in the assembly. I like to use a high quality elastomeric type sealant like Big Stretch rather than silicone mentioned on the Attach-A-Deck instructions. Most types of silicone won’t stretch much before the bond breaks whereas an elastic sealant will maintain a seal when building components like siding moves.

Attach-A-Deck devices are available online through the website for $8.95 per pair or some lumber yards where the Attach-A-Deck system has become popular. A 12 ft. deep deck joist span (house to beam) and 16 ft. long (length of ledger) will need 22 Attach-A-Deck spacers which will run you about $100. Attach-A-Deck is more economical than old-school methods of ledger mounting when you figure the time you save removing siding and installing flashing on a conventionally mounted ledger, not to mention the savings on flashing and peel and stick membrane.

Furhter Resources:

Deck Ledger Bolting by the Code

How to Attach a Deck Ledge to the House

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Affordable IR Camera

Handy Heat Gun

Reliable Crimp Connectors

View Comments

"Malicious Web Site Blocked

You attempted to access:

http://www.attachadeck.com/

This is a known malicious web site. It is recommended that you do NOT visit this site."

This is the message my Norton Internet Security software displayed when I tried to access that website. Access it at your own risk.

Went there (http://www.attachadeck.com/) and had no problems,even opened pdf.

I have the full Norton suite but never had trouble accessing Attach-A-Deck's site nor a warning. Perhaps an anomaly.

Tried to access the website and between McAfee Anti-virus, Firefox and WOT every malicious website/phishing alarm went off. Don't know what the problem is.

Sorry to anyone who had a problem logging in to the Attach-A-Deck website. Complete scans have been run by Norton and the webmaster and the site was determined to be virus free. It was determined by Fine Homebuilding computer personal and my webmaster that the alerts were caused by the underlined word Attach-A-Deck being a direct link in the article 11 times which created a spam alert on some virus protection programs. If you have any problems with the site, please contact me @ jeff@attachadeck.ccm . Thank you, Jeff Johnson, owner of Attach-A-Deck.