TetraGrip

The TetraGrip subfloor fastening system eliminates the need for adhesive

When subfloor panels absorb moisture, they can expand, causing the nails to pop up. With the nail heads raised slightly, the subfloor is free to slide up and down the shank of the nail, which is what causes a floor to squeak under foot. A traditional solution to this problem is either a healthy bead of adhesive applied to the top of each floor joist before the panel is nailed home or the use of screws in addition to, or instead of, nails. Paslode aims to provide a better solution with its TetraGrip nail, which the company says “drives like a nail, holds like a screw.”

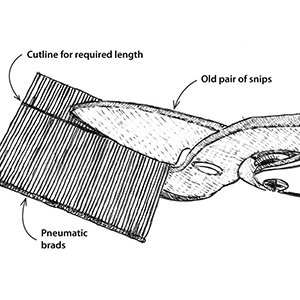

Each TetraGrip nail has barbed helical threads that run from the tip all the way to the head. Unlike a traditional ring-shank nail, which can crush the wood fibers as it’s being driven, TetraGrip nails spin down into the wood like a screw.

TetraGrip nails are code-approved, but they must be installed with Paslode’s PF237C Subfloor Coil Nailer. Each nail is 23⁄8 in. by 0.113 in. dia., equivalent to a 6d nail. Code typically requires 54 nails per panel, but the superior holding strength of TetraGrip nails allows them to meet code with only 38 nails per panel.

Bottom line: We haven’t field-tested these new nails, but if they work as well as Paslode claims and eliminate the need for adhesive, lots of builders will be interested. Here’s the catch, though, and it’s a big one: Paslode is selling this system only direct to builders. The price you pay for nails and nailers will depend on quantity, and Paslode was unwilling to share even a theoretical pricing structure with us. Builders must first do a cost analysis with a representative from the company, a hoop that many people will likely not want to jump through.

Comments are closed.