4 Options for Shear Bracing Foam-Sheathed Walls

If you aren’t building in a high-wind area, continuous sheathing is likely to cost more than other bracing solutions. This article discusses four alternatives for shear bracing foam-sheathed walls.

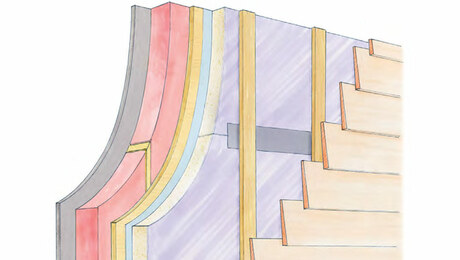

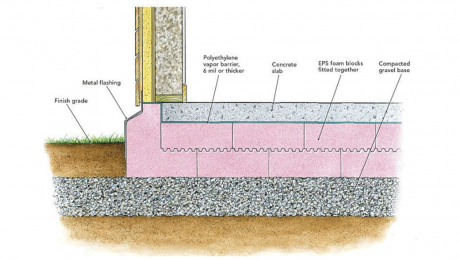

In many parts of the United States, it’s becoming common for builders to install rigid-foam sheathing on the exterior of framed walls. However, this raises a potential problem: Because rigid foam isn’t structural, how are the walls braced to prevent racking? There are at least five ways to brace a foam-sheathed wall, the first of which most builders and inspectors are familiar with.

Using continuous plywood or oriented-strand-board (OSB) sheathing under the foam allows you to use the prescriptive section of the code—a simpler route than an engineered solution—even in high-wind areas. Where rough-cut 1-in. boards are available from local sawmills, diagonal board sheathing is also worth considering. It is a strong, vaporpermeable, code-approved method of bracing walls. If you aren’t building in a high-wind area, however, continuous sheathing is likely to cost more than other bracing solutions. Here are four alternatives.

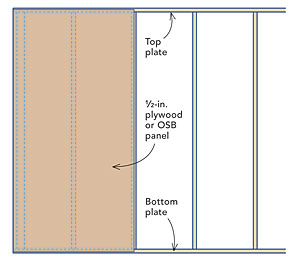

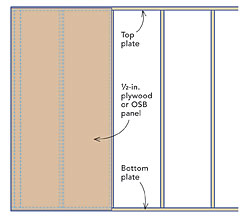

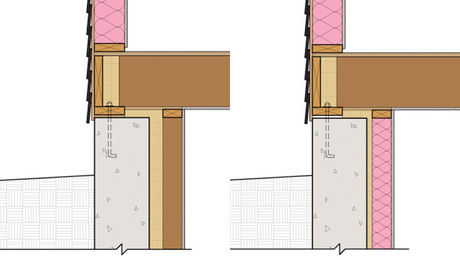

Plywood or OSB at critical areas

It’s possible to brace a wall with just a few sheets of plywood or OSB. A small house may require only two sheets of OSB per wall, usually located at the corners. Long walls also may require an additional sheet in the middle of the wall. Most builders rely on an engineer to specify the number of required sheathing panels, their placement, and the nailing schedule.

Once the plywood or OSB panels have been installed, the rest of the wall is sheathed with rigid foam. Two thicknesses of rigid foam are necessary to complete the job. For example, if 2-in.-thick foam is used between the OSB sheets, then 1-1/2-in. foam is used to cover the OSB.

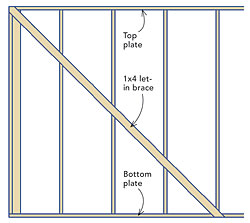

1×4 Let-in bracing

The traditional method of bracing unsheathed walls is to use 1×4 let-in bracing. Set in a notch cut into the studs and plates, the 1×4 must extend from the bottom plate to the top plate, and it must be securely nailed to each plate and stud. According to the International Residential Code, “The let-in bracing shall be placed at an angle not more than 60° or less than 45 degrees from the horizontal.”

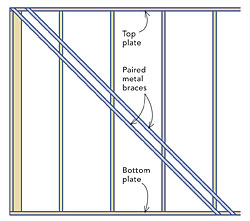

Diagonal metal strapping

There are at least three kinds of steel strapping used to brace walls: flat strapping, T-profile strapping, and L-profile strapping. All three types need to be installed from plate to plate and must be wrapped around the top or bottom of the plate. The location and frequency of metal strapping depends on many variables and is usually determined by an engineer.

Flat strapping (for example, Simpson WB) works only in tension, not in compression. For that reason, flat strapping must always be installed in pairs that form the shape of a V or an X.

T-profile strapping and L-profile strapping are designed to be installed by inserting one leg of the strapping into a 1/2-in.-deep kerf cut into the studs and plates, and then nailing the strapping to each stud and plate. T-profile and L-profile strapping have an important advantage over flat strapping: They work in both compression and tension. That means they need not be installed in V-shaped or X-shaped pairs.

Not all types of T-profile and L-profile strapping have passed the tests that allow them to be substituted for code-required 1×4 let-in bracing. While Simpson Strong-Tie’s L-profile strapping (RCWB) is made of 20-ga. steel and is considered a prescriptive-code bracing material, Simpson T-profile strapping (TWB) is made of thinner 22-ga. steel and does not meet prescriptive-code requirements. If flat strapping or T-profile strapping is used for wall bracing, it must be part of an engineered design.

L-profile metal strapping is a good bracing solution in many areas; however, the capacity of metal bracing may not be adequate in high-wind or seismic areas.

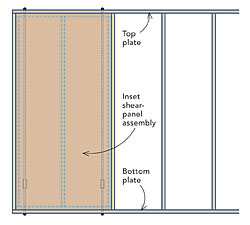

Inset shear panels

Walls framed with 2x6s can be braced with inset shear panels. These reinforced boxes are framed with 2x4s and sheathed with OSB. Because each panel is 4-6-1/2 in. wide and 4 in. deep,it can slip into a 2×6 wall in a wide bay created by removing one stud. The height of the shear panel allows it to fit between the bottom and top plates of the wall. Because the OSB sheathing on an inset shear panel is flush with the studs, the shear panel does not interfere with the installation of foam sheathing.

Inset shear panels obtain much of their strength from threaded rods that join the top and bottom plates; these rods are sometimes connected to carefully placed anchor bolts by means of threaded couplings.

The work of designing inset shear panels, specifying how many to use, and deciding where to place them in a wall is best left to an engineer. If designed correctly, inset shear panels can provide enough lateral load resistance to work in all wind and seismic zones.

When in doubt, call an engineer

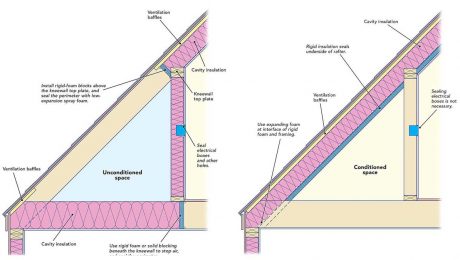

Before finalizing a wallbracing plan, it makes sense to talk to your local building official. In the 2006 and 2009 International Residential Code (IRC), wallbracing requirements can be found in section R602.10. The code specifically allows several wall-bracing methods, including the use of 1×4 let-in bracing, diagonal board sheathing, panel sheathing (plywood, OSB, or gypsum sheathing), portland-cement stucco, hardboard panel siding, and “alternate bracedwall panels.”

Of course, builders in seismic zones and highwind zones must meet more stringent requirements than builders in the rest of the country. IRC table R602.10.1 includes prescriptive solutions to brace walls in different wind-speed and seismic design areas. If you have any doubts about your chosen method of wall bracing, it makes sense to consult an engineer.

Drawings: Steve Baczek

View Comments

Since this was written testing in Oregon has shown that 1/2" ply on the outside of the foam, attached at 4" edge nailing with 16d nails outperforms standard shear sheathing. In this case, you get full foam, full sheathing and a great surface for attaching house wrap & siding.

ehje1624

How thick can the foam be under the method described in Oregon?