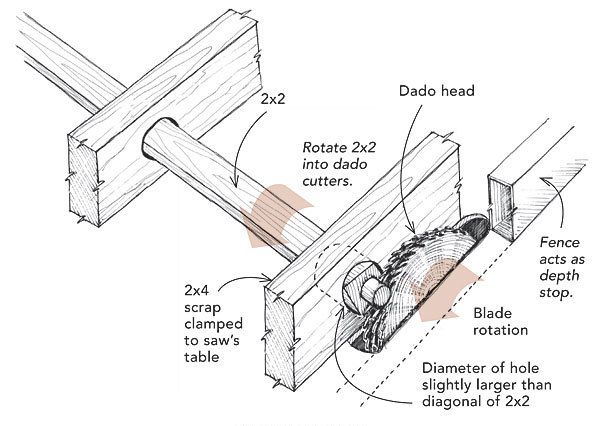

I recently built a railing for a customer’s deck, and I used 2x2s for the spindles. For strength, I used a mortise- and-tenon assembly. The challenge became cutting quick, accurate tenons on the ends of the 2x2s.

As shown in the drawing, I clamped a pair of scrap 2x4s to the top of my tablesaw. I bored a hole in each 2×4 sized to allow a 2×2 to be pushed through and rotated into the spinning dado head. Raising or lowering the dado head controls the diameter of the tenon. I positioned the rip fence to act as a depth stop. Once I had this setup dialed in, it was simply a sequence of pushing and turning the 2x2s to cut the tenons.

Peter Blackmore, Courtenay, None

Edited and Illustrated by Charles Miller

From Fine Homebuilding #220

View Comments

I like this but it would seem safer if either more surface area against the fence ,or a slot runner were added to the bottom of inner 2 by material. That would maintain parallelism with the fence.