Video Vault: Cut Tenons for Deck Rails With a Tablesaw

How to make a tenoning jig for a tablesaw and cut the tenons for deck balusters.

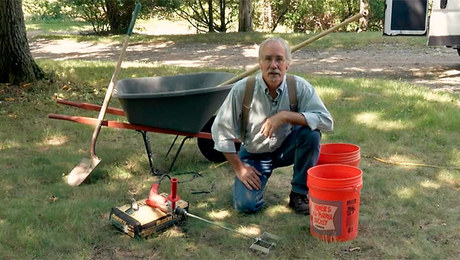

If you need to put tenons on your deck-rail balusters, you could put dowels in the ends of them, or try to find a lathe, but there’s a better way. In this gem from the Fine Homebuilding Video Vault, Chuck Miller shows us how to make a tenoning jig for a tablesaw and how to cut the tenons for deck balusters.

More Video Tips

Keep Your Truck Tailgate Clear With a Simple Gravel ShieldA How To Hang Drain Line So They Stay Straight And Secure

Roll Compound On Your Drywall Seems For Faster, Easier Taping

Tablesaw trick

This tip is from Peter Blackmore from Courtney, British Columbia. He’s discovered a way to use a dado head and a scrap-wood jig to cut accurate tenons.

Build a jig with a few 2x4s and clamps

The dado head should be sandwiched between the guide rail and the fence on the other side. Two guide rails with a hole bored that is the same as the diagonal dimension of the baluster allows the baluster to be rotated through perpendicular to the blade. The fence is used as a depth stop and the distance from the fence to the dado head adjusts the length of the tenon. The height of the dado head adjusts the diameter of the tenon.

Note, the baluster should be turned the same direction as the rotation of the blade. Go slowly. And to stop tear out, wrap the end in masking tape.

View Comments

Hi Chuck,

On your nice video How to Cut Tenons for Deck Rails with a Table saw you are indicating to rotate the tenon rod the same direction as the saw rotates but the actual rotation is the opposite direction / counter clock.

Thanks

Gideon Levinson

Hi Gideon,

Glad you like the tenon tip. It's a useful way to cut a cylindrical tenon on all kinds of workpieces. Our tipster David Kalin in Hawaii uses a much larger version of this to profile cylindrical ends on 4x4 fence posts, which he then encases in pvc pipe to thwart the termites.

Regarding the rotation of the workpiece in this video. Please have another look. I am rotating it counter clock wise--the same rotation as the dado blades. In this manner, the workpiece is rotated into the advancing teeth.

best,

Chuck

Awesome Tip , I was considering a small lathe purchase because I had a small job that required this but now no need to purchase an additional tool that I may not utilize often.

The video plays in Chrome but not in Safari 10.1.1.

Excellent tip!

Keep it up!! Thanks for sharing this blog.