Synthetic Roofing Underlayments

These materials are tougher than felt, but do they perform as well?

Synopsis: The traditional choice for roofing underlayment is asphalt felt, but as technologies have developed, manufacturers are offering more synthetic underlayments. Senior editor Martin Holladay takes a look at the various types of synthetic roofing underlayments and considers their pluses and minuses compared to felt. The biggest issue with many synthetics is permeance, which makes them effective vapor barriers. However, a strong vapor barrier is an asset only for certain roof styles. Care must be taken when attaching synthetic underlayments; cap fasteners are the best choice. Traction is also an issue as some synthetics can be slippery.

NOTE: All material prices fluctuate over time, so the prices listed in this article are more for comparison than for providing accurate cost estimates.

A milestone in any construction project is drying in, usually defined as the day the roof sheathing is covered with underlayment. Building codes require the installation of asphalt felt for several reasons: Underlayment keeps the sheathing dry until the roofing is installed, it provides some protection against leaks in case wind-driven rain gets past the roofing, and it provides a slight improvement in a roof’s fire resistance.

For years, roofers chose between basic #15 or heavier #30 asphalt felt, which are commodity products sold under many brand names. Both types of felt are made from recycled corrugated paper mixed with sawdust; to provide water resistance, the paper is impregnated with asphalt. These days, however, roofers also can choose from a variety of synthetic roofing underlayments: sheet products made of laminated polypropylene or polyethylene plastic.

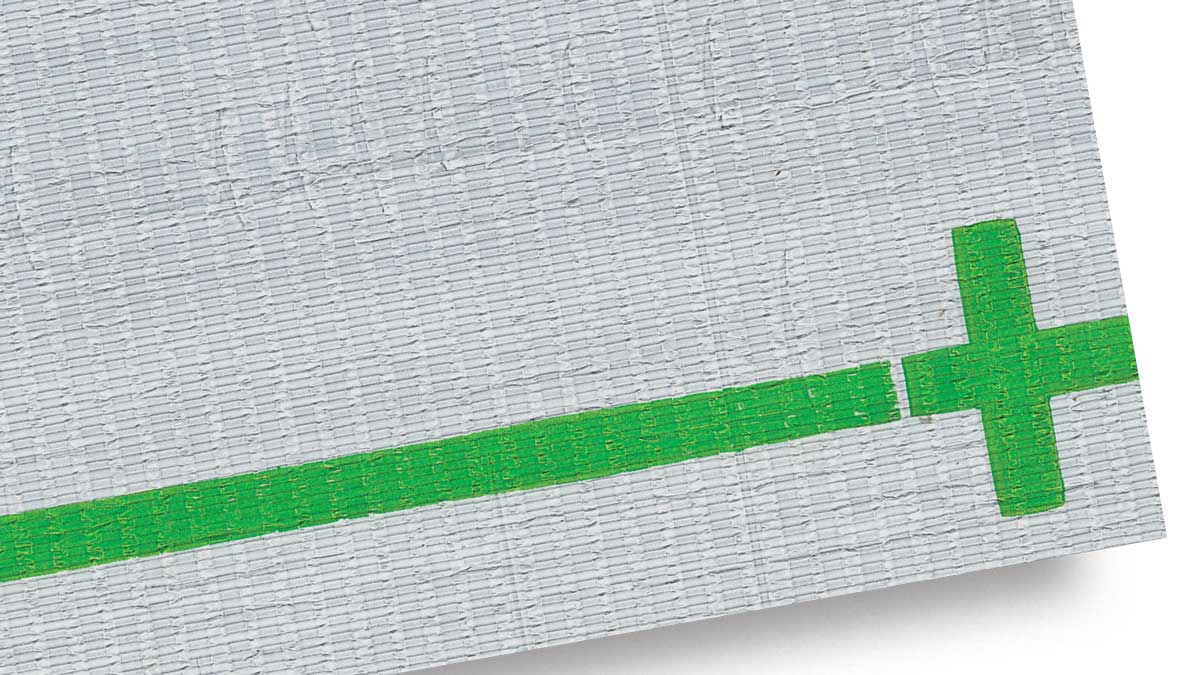

Synthetic roofing underlayments look and feel similar to housewrap. Unlike housewrap, though, most synthetic roofing underlayments are vapor barriers, so they shouldn’t be used on unventilated roofs.

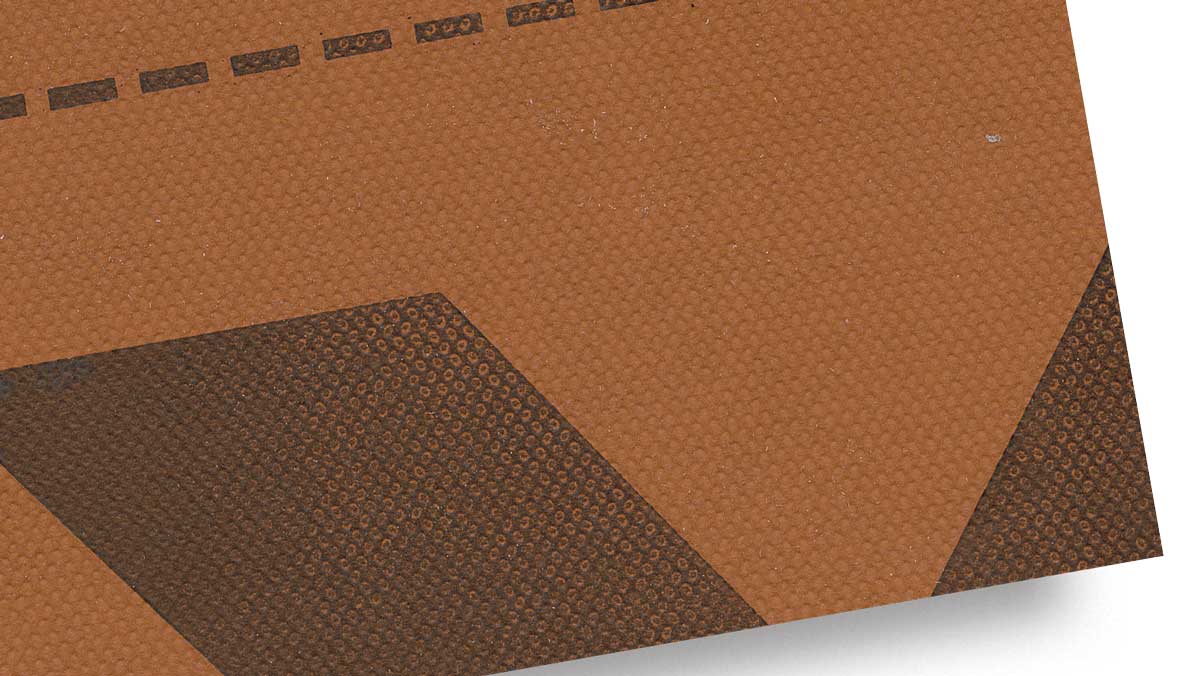

These plastic underlayments also offer higher resistance to UV radiation, better traction for roofers, and more square footage of coverage at a lower weight. They are not, however, intended or approved to replace peel-and-stick membranes in areas prone to ice dams.

Synthetic vs. Felt: The choice isn’t cut–and–driedTypical sizeSynthetic: About 4 ft. by 250 ft. Felt: 3 ft. by 72 ft. to 144 ft.

Vapor PermeabilitySynthetic: Typically not vapor permeable Felt: Vapor permeable

ExposureSynthetic: Pliable and resilient; can be exposed even to cold weather for between four and 12 months Felt: Wrinkles when wet; cracks and splits in cold weather

DurabilitySynthetic: Highly tear-resistant and hard-wearing Felt: Tears easily in high winds and under foot traffic

Required fastenersSynthetic: Must be installed with cap nails or cap staples Felt: Can be installed with staples or roofing nails

Cost (per sq. ft.)Synthetic: Vapor impermeable: 11¢ to 15¢; vapor permeable: 20¢ to 90¢ Felt: #15: 5¢; #30: 10¢

Bottom lineSynthetic: When compared to asphalt felt, synthetic roofing under-layments have many of the advantages of housewrap: They install quicker and are far more durable in high winds or when left exposed for long periods of time. They also offer better traction than asphalt felt. These benefits must be balanced against the higher cost of synthetics, though, especially for vapor-permeable products. The need for cap fastening also means a standard hammer-stapler is no longer an option. Felt: Asphalt-felt roofing underlayment has been in use for a long time, and for good reason. It’s widely available, is inexpensive, is simple to install with common tools, and is the original “smart” vapor retarder, changing its permeance depending on whether it’s dry or wet. It’s still the product of choice for roofers who are drying in and installing the finished roofing with only short exposure to the elements between. |

Traditional felt still competes with newer synthetics

Although synthetic roofing underlayments have several advantages over asphalt felt, asphalt felt remains popular as a roofing underlayment for several good reasons.

While the price of asphalt felt fluctuates somewhat, it’s still the least expensive option. Builders typically pay about 5¢ per sq. ft. for #15 felt and 10¢ per sq. ft. for #30 felt. Synthetic underlayments cost more than twice as much as #15 felt — usually between 11¢ and 15¢ per sq. ft. Vapor-permeable synthetic underlayments are even more expensive — from 20¢ to 90¢ per sq. ft.

According to Dyami Plotke, a manager at Roof Services in Islip, N.Y., “For a standard roof assembly, where the felt and asphalt shingles are installed on the same day, it doesn’t make any difference what underlayment you use, so the lower cost of the standard felt is a big advantage. Where the synthetics outperform felt by a mile is in their tear resistance. Synthetic underlayment allows us to bring a building to a watertight condition just by papering it, without installing the roofing immediately — and it will stay watertight for months. That’s why we always use synthetic underlayment under specialty steep-slope products like slate and tile, which are slow to install.”

Cap fasteners aren’t optional

Although asphalt felt doesn’t seal around fasteners as effectively as peel-and-stick membranes, it is less likely to leak at nail and staple penetrations than a synthetic underlayment. Synthetic underlayment punctured by staples or common roofing nails can, with the help of capillary action, lead to leaks. That’s why plastic-cap nails or staples, which help to seal penetrations, are a must when installing synthetic underlayments. Cap fasteners can be installed with a compatible pneumatic tool or, in the case of cap nails, manually.

Some roofers also have reported that synthetic underlayments allow more wicking at laps than asphalt felt. For areas that need sealing—including vulnerable laps—use caulk rather than the traditional black roofing cement.

Features aside, it comes down to permeanceNot-so-slippery slopeAlthough Grace’s Tri-Flex Xtreme is skid-resistant when dry, its surface is designed to swell slightly so that it becomes even more tacky when wet. Doesn’t mind construction delaysMost synthetic underlayments can be left exposed for six months and some for 12 months. The woolly, tan-colored Opus Roof Blanket, though, is approved for 30 months of UV exposure. Breathe easyRated at 550 perms, Cosella-Dörken’s Delta-Foxx underlayment is by far the most vapor-permeable product in this category, making it ideal for use over unvented assemblies or under slate, clay, or tile roofing. Most synthetic underlayments have permeance ratings under 1 perm, making them effective vapor barriers. Because these underlayments don’t allow roof sheathing to dry upward, manufacturers recommend that they be used only over ventilated spaces (that is, vented cathedral ceilings or vented attics) that allow downward drying. Of course, just because an attic is currently vented doesn’t mean it will stay that way. A few years down the road, a homeowner might decide to install spray polyurethane foam on the underside of the roof sheathing; at that point, the sheathing will no longer be able to dry downward. If this possibility worries you, stick with asphalt-felt underlayment. (Asphalt felt is the original “smart” vapor retarder; it has a permeance of about 5 perms when dry, but a much higher rating of 60 perms when wet.) Although underlayment manufacturers often don’t distinguish between different types of roofing when making ventilation recommendations, some experts do. According to building scientist Joseph Lstiburek, “Having a vapor-permeable underlayment is a big deal if you have a tile roof or a cedar-shingle roof—a roof that is assembled like a vented rain screen. It’s very beneficial to be able to dry the roof deck upwards. But the permeance of the underlayment doesn’t matter when asphalt shingles are involved.” In other words, if you are installing a type of roofing that doesn’t allow upward drying, you don’t have to worry about the permeance of your underlayment. Lstiburek tempers his advice with the commonsense observation that underlayment permeance isn’t worth obsessing over. “The permeance of the underlayment is irrelevant if everything blows off the roof,” he says. “This vapor-permeance is arcane stuff, and none of it matters if you forget to fasten and flash everything properly.” Although most synthetic underlayments are vapor barriers, there are exceptions. Several manufacturers produce products with a vapor permeance that is as high as, or even higher than, asphalt felt. The higher the permeance, the faster water vapor can pass through a material. Any material with a perm rating of 10 or greater is highly permeable. These products are signifi-cantly more expensive than vapor-impermeable underlayments, so if you want a vapor-permeable product, you may prefer to stick with asphalt felt. A final note: Although it’s perfectly acceptable to use asphalt felt on the roof and as a water-resistive barrier on walls, the same isn’t true of vapor-impermeable synthetic roof underlayments. These products are not approved for use on a wall, unless, of course, you’re using one of the vapor-permeable options. |

Exposure limits and warranties

In their technical-data sheets, manufacturers of synthetic roofing underlayment list maximum time limits, ranging from two months to 30 months, for exposure to the weather. A word of warning, however: There is little evidence that 12-month products actually perform differently from four-month or six-month products, so it doesn’t make much sense to rely on these numbers when selecting a product.

Despite the fact that Cosella-Dörken’s underlayments have an excellent reputation for durability, the company recommends that roofing be installed “as soon as possible.” Product manager Peter Barrett explains, “Plastic begins to degrade as soon as it is exposed to UV light. Once degradation starts, it will go on, even when covered by roofing, since heat and oxidation continue to act on the plastic. Most manufacturers are just giving a guess on the durability of their products. They’re gambling that nobody will actually uncover them to see how they’re holding up. Warranties are mostly used as marketing tools; these numbers are not an expression of durability.”

Which brand should I choose?

Most roofers aren’t too picky about which brand of synthetic underlayment they use, and in many cases, the options will be dictated by your specific region. “In terms of performance, I think that synthetic felt is a commodity product,” says Plotke. Because slippery underlayments can be dangerous, the deciding factor for many roofers is traction. According to evaluations made by Fine Homebuilding editorial adviser Mike Guertin, the tested underlayments that showed the greatest slip resistance in both wet and dry conditions were Titanium UDL, RoofLiner, and Tri-Flex Xtreme. Under wet conditions, Sharkskin didn’t perform as well as the top-rated underlayments. This segment of the market is growing quickly, however, and there are well over a dozen products that Mike has not had the opportunity to investigate.

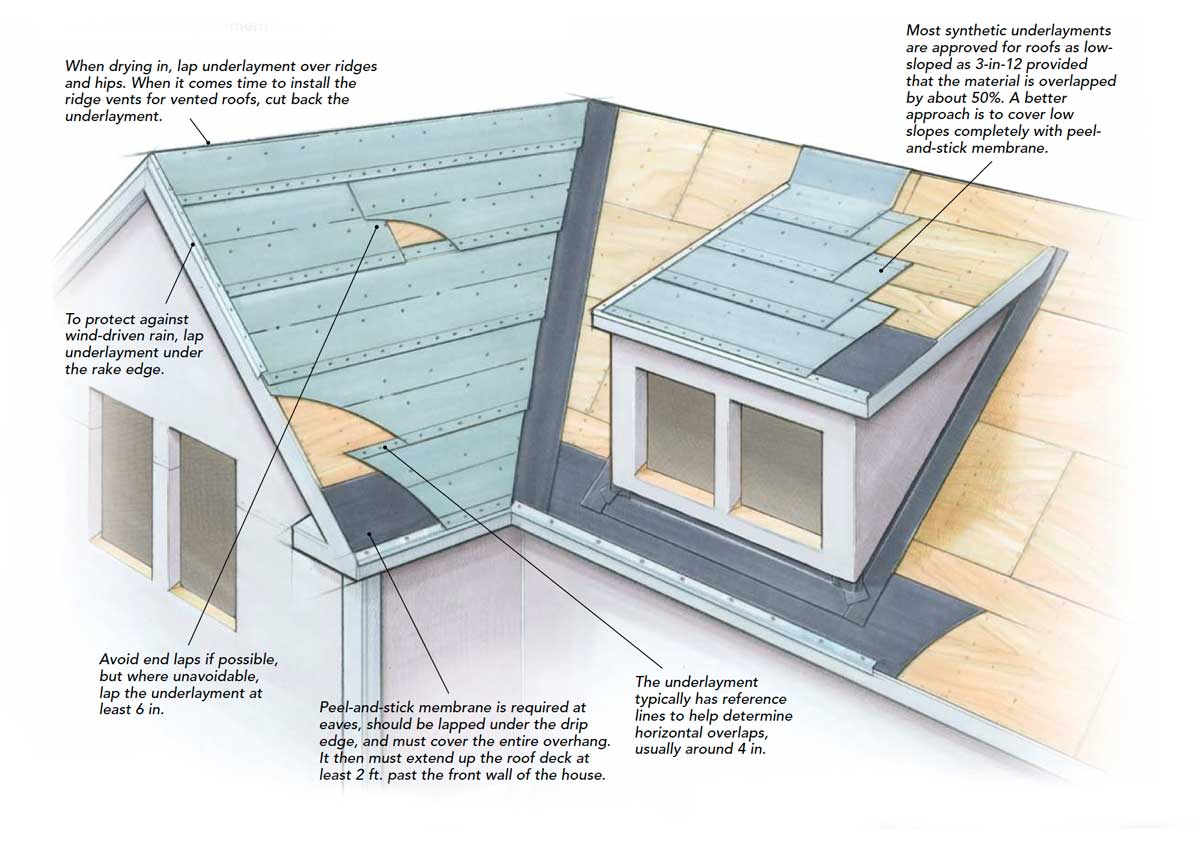

Tailor the installation to the roofAsphalt-felt roofing underlayment has specific installation instructions outlined in the code book. To date, there are no such code guidelines for synthetic underlayments, so the installation for these products is dictated by manufacturers. Below are some of the more generic details, as well as areas that may differ from brand to brand. Not installing synthetic underlayment according to manufacturer requirements is a quick way to void the warranty.

|

Martin Holladay is a senior editor.

From Fine Homebuilding #222

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Roof Jacks

Ladder Stand Off

Peel & Stick Underlayment

View Comments

What about underlayments for snap lock type standing seam metal roofs especially when the metal roof will be installed right onto the sheathing (no battens or air gap beneath the metal)? I would imagine that under that metal it will be getting very hot. Are there synthetics made to with stand those temps and if so what are they? What is recommended, in that situation?