by Michael Chandler

From Fine Homebuilding #223, p. 12-16

When designing and building highperformance kitchens and baths, we may find it exciting to use products that bring new textures and style into a home while offering water, mold, stain, and fire resistance. Unfortunately, some of these products may introduce toxic dust and gases as well, and it’s not just the kitchen and bath finishes that we need to be concerned with. It’s the insulation we choose to make our homes efficient, the furniture we choose to make them comfortable, and the products we choose to keep them clean.

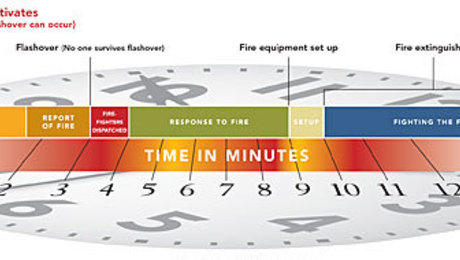

With range hoods and exhaust fans standard appliances in our kitchens and baths, these rooms offer the opportunity to help keep indoor-air quality high, but a commercial-size hood fan alone is not a solution. In fact, without proper makeup air, that beautiful appliance may be doing more harm than good. Tight homes, toxic chemicals released from building materials as gas and dust, moisture, improper ventilation, and combustion appliances are a combination with the potential to cause asthma, infertility, birth defects, behavioral problems in children, and cancer. Backdrafting carbon monoxide can kill quickly.

The problem is that it’s perfectly legal for manufacturers to list toxic chemicals as “trade secrets” on their products’ material-safety data sheets (MSDS) or to exclude items that are subcomponents of other ingredients. The lack of clarity about chemical threats is made worse by the variability of human chemical sensitivity. Some common toxins cause immediate reactions in only a small part of the population. Others are accumulative, causing symptoms only after prolonged exposure. Many are bioaccumulative, meaning that they escape the house and accumulate in the oceans, fish, and, ultimately, those of us who eat seafood. Even if we as designers and builders could create a perfectly healthful home, toxic chemicals could still be introduced through furniture, clothes, shoes, gasoline stored in the garage, and solvents in everyday cleaning products.

Healthful indoor-air quality is the result of three guiding principles: choosing healthful materials, handling and installing them with caution, and providing right-size ventilation with appropriate makeup air. We’ll get to proper ventilation soon, but let’s first look at some materials that must be used with care, if not avoided altogether.

Start with(out) VOCs

It’s important to realize that it is not possible to ventilate enough to make up for toxic products brought into the home in building materials and furnishings. It is possible, however, to know which products are more likely to pollute the indoor environment and to minimize their use by substituting safer alternatives. Volatile organic compounds (VOCs), often found in paints and finishes, caulks and sealants, and cabinet sheet goods, are known to cause a number of adverse health effects in human beings; some are even known to be carcinogens.

Fortunately, low-VOC finishes, caulks, and sealants are now readily available at most lumberyards and home centers. There are low-VOC and low-formaldehyde sheet goods available for cabinet construction. See the Kitchen Cabinet Manufacturers Association website for certified products (www.kcma.org). Eliminating VOCs from your project is a good start, but there are other harmful chemicals to look out for as well.

Shower-curtain liners, plastic glazing panels, vinyl organizers in kitchens and closets, and vinyl wallpaper are all likely to have phthalate plasticizers, which the EPA lists as “a concern for development in the male reproductive system.” Glass shower enclosures and cabinet and closet organizers made of wood are a better choice. Skipping vinyl wallpaper also makes sense because it can prevent walls from drying and lead to mold growth.

Handle with care

One of the most prevalent classes of toxic chemicals in home-building materials is the halogenated flame retardants used in foam insulations, soft urethane furniture foam, draperies, and furniture fabrics. Several of these are listed by name in the EPA’s Action Plan for chemicals of concern (www.epa.gov), but there are more than 75 chemical flame retardants in use in America, with new, untested products coming from Asian manufacturers and a new class of polymerized flame retardants being marketed as “green” alternatives. Because they are listed as “trade secrets” on MSDS sheets, it is difficult to determine which are safe to use.

Halogenated flame retardants were originally introduced as an alternative to previous chemical flame retardants that were discovered to be carcinogenic. The new products aren’t known to be carcinogenic, but have been linked to endocrine disruption, birth defects, and infertility. They are classified as persistent and bioaccumulative toxins by the EPA, which means that they are not biodegradable and that they tend to concentrate in the food chain.

Formaldehyde and high-VOC products contaminate the home by outgassing. Flame retardants are released through degradation of the material into particulate dust solids. The best way to minimize toxic flame retardants in homes is to minimize the use of foam products and flame- and stain-resistant fabrics. When choosing spray foam, ask what flame retardant is used, and select those that use TCPP (tris [2-chloroisopropyl] phosphate), which is less toxic but still nonbiodegradable, or TEP (triethyl phosphate), which is less toxic and also biodegradable. Bayer Agribalance

uses TCPP.

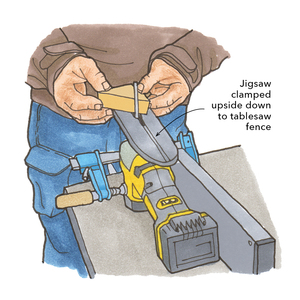

Save spray foam for band joists and other areas where it doesn’t need to be trimmed. Keep children and people of child-bearing age away from spraying operations until the product has cured for three days. When using rigid foam, do the cutting outdoors or in a place where the dust can be contained and disposed of. Know that polyisocyanurate rigid foam typically contains less flame retardant than extruded polystyrene, with a higher R-value to boot.

Solidsurfacecountertops also may contain large quantities of flame retardants and should be cut and sanded in a place where the dust can be contained. When remodeling, take great precaution when tearing out potentially toxic materials like old foam and rebond foam carpet padding.

Ventilate right

The goal of ventilation design is to exhaust humidity and bad odors while bringing in enough fresh air for healthful living—but not so much that it adds unnecessarily to the heating, cooling, and dehumidification load. What happens too often, however, is that instead of hiring an engineer to do the load calculations for a right-size ventilation system, an oversize system is installed. Moreover, we often try to incorporate ventilation into the home’s HVAC system. Trying to address ventilation with the HVAC blower can inadvertently lead to a house that is excessively ventilated when it’s hot and humid or bitter cold. You can keep your ventilation system separate from the HVAC system by using your kitchen-range-hood and bath fans and providing adequate makeup air.

The magic number for air changes in a healthful home is theoretically 7.5 cu. ft. per minute per occupant. If a house has two occupants an average of 14 hours a day, that’s 14 hours x 60 minutes x 7.5 cfm, or 6300 cu. ft. of fresh air a day for each occupant. That’s the same as running a 100-cfm bath fan for 63 minutes. You can achieve this by putting bath fans on motion sensors with a timer that is set to 30 minutes per bathroom visit.

Using an HRV for bathroom ventilation makes even better sense because any air that is taken out of the house by ventilation fans needs to be replaced by air from the outside. Without a plan for makeup air, it is likely to be pulled through the crawlspace or attic where it may pick up mold spores, humidity, or toxic dust particles. An HRV brings in equal amounts of fresh air to replace the stale exhaust air, helps to reduce the pressure imbalance that can be caused by exhaust ventilation, and saves energy. Unfortunately, you can’t use an HRV on the greasy air exhausted by a kitchen hood, and some hoods over 200 cfm can depressurize a house enough to pull ashes out of the fireplace and cause combustion appliances to spill carbon monoxide into the home.

We saw one Energy Starrated house that was depressurizing so much that it was pulling lawn-mower clippings in through leaks in the returnair ducts in the crawlspace and distributing them through the air-conditioning onto the furniture. If your client must have an oversize range hood, make sure to provide an intakeair vent to relieve the depressurization. I also install a speed controller on the hood so that the cook can adjust the airflow and dial down the fan noise. If the hood is more than 400 cfm, it’s worthwhile to install a powered intake-air vent. Typically, this will be an in-line fan sized for the same duct as is called for by the hood fan. It should be on the same switch or speed controller as the hood.

Finding a speed controller robust enough to handle this type of load can be a challenge, as can diffusing the draft. If the laundry room is open to the living space, you may find that placing the intake behind the washer and dryer is your best bet. The easiest solution is to stick with variable-speed hoods in the 200-cfm range and to use a passive intake closer to the point of exhaust.

Market-based solution

As you can see, designers and builders can make choices to build healthful homes without sacrificing performance. It may be impractical, though, to expect all designers and builders to do the necessary research to understand the dangers of certain products and find viable alternatives, and regulations rarely work. The overarching solution is to create market conditions where people routinely ask for full material-safety disclosure from manufacturers. Before people started asking for low-VOC paints, Sherwin-Williams ProMar 200 flat latex was 260 grams/liter VOC and Duron Builder Masterpiece was 50 g/l. Now that low-VOC is a marketable advantage, Sherwin-Williams has acquired Duron, and its ProMar 200 is 50 g/l.

Finally, there is no point to building a healthful home only to have it polluted with fabrics, furnishings, and cleaning chemicals after the occupants move in. If you are a designer or builder, educate homeowners about toxic materials. Explain that you did everything possible to build them a healthful home, but that they have to make healthful choices now to keep it that way. This information would be perfect to add to your homeowners’ manual along with recommendations about less toxic furnishings, cleaning supplies, and other products that may be brought into the home. Also, give them a schedule for cleaning or changing air filters. They not only clean the air but also save energy.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Handy Heat Gun

Affordable IR Camera

8067 All-Weather Flashing Tape