Installing Stock Cabinets

Master these pro techniques for hanging cabinets to achieve a flawless new kitchen.

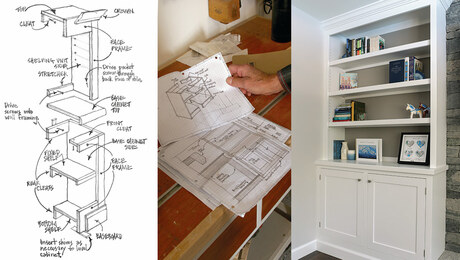

Synopsis: In this article, veteran kitchen designer and installer Rick Gedney shares his approach to installing cabinets. He explains how to organize the job so that it moves along efficiently, how to prep the site, how to achieve an accurate layout, and how to install the three most common types of kitchen cabinets: base cabinets, wall cabinets, and tall units that serve as pantries or that often house refrigerators or ovens. He also provides instructions for hanging wall cabinets safely even when you are working alone. He recommends installing cabinets when the kitchen is almost finished. The flooring should be in place and, if it’s wood, should have one or two coats of finish on it. Likewise, the ceiling and walls should be primed and painted. Working in a fairly finished environment such as this demands substantial care and dust control, and Gedney suggests removing tool belts and cordoning off the kitchen with a dust barrier.

My father started working in the kitchen industry in the early 1950s. I spent many of my high-school days making cabinet deliveries and installing appliances. In 1979, he and I opened a small business together, Kitchens by Gedney. In one way or another, I’ve spent nearly 35 years designing, installing, and managing the installation of high-end kitchens.

A lot has changed in the kitchen industry since those early days. What hasn’t changed is the demand for flawlessly installed cabinetry, a standard we’ve been committed to for nearly two generations.

Over the years, I — along with our skilled installation crews — have developed an approach to installing cabinets that ensures accuracy and quality. Here, I’ll explain how to organize the job so that it keeps moving forward, how to prep the site properly, how to achieve an accurate layout, and how to install correctly the three most common types of kitchen cabinets: base cabinets, wall cabinets, and tall units that serve as pantries or that often house refrigerators or ovens.

Have a plan to stay organized

Whether in a remodel or a new home, the installation of kitchen cabinets involves high levels of stress and activity. In a remodel, you’re occupying the space that makes the home habitable. Getting the job done as quickly as possible is almost always the goal. In new construction, you’re working amid a host of other subcontractors, all vying for space. In either environment, the room for error is significant. We keep our jobs accurate and in order with communication, a plan review, and a systems approach to installation.

Communication is critical. Create an installation calendar so that everyone involved in the project knows what’s happening in the kitchen and when. Be sure to have established contacts with the cabinet supplier so that if a question or error arises, you can make a quick call to the person who can remedy the problem.

Before a single cabinet is uncrated, review the plan with your designer or cabinet supplier to be sure all cabinets are on site. Be sure you understand the supplier’s terminology, because most cabinetmakers have their own codes and product numbers. Then be sure that all the labels actually match the cabinets in each package. Nobody wants to demolish a kitchen only to realize that the new corner base cabinet is the wrong size and that the correct unit is on back order for four weeks.

Establish a repetitive system, from site prep through installation, to be sure the job progresses as it should. Having a systematic approach makes cabinet installation more accurate, and it also saves time. With this system and two people on the job, expect to install the cabinetry for a typical kitchen in about three days. Another three days will likely be spent applying moldings, installing appliances, and completing ventilation work.

For more photos and details, click the View PDF button below: