In its newly inaugurated Lab Homes project, the Pacific Northwest National Laboratory has tried to make it easy to accurately measure the effects of energy efficiency retrofits.

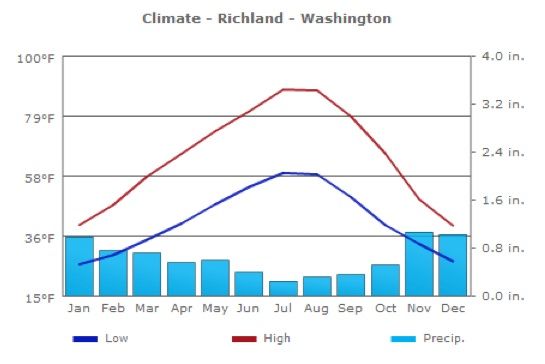

Rather than relying on modeling data based on imaginary reference homes of comparable size, Lab Homes focuses on the performance of two factory-built 1,500-sq.-ft. doublewide homes set up side by side on the PNNL campus in Richland, Washington. Both homes have been tested for airtightness, duct leakage, and, using infrared imaging, thermal performance to make sure they are as close to identical as possible.

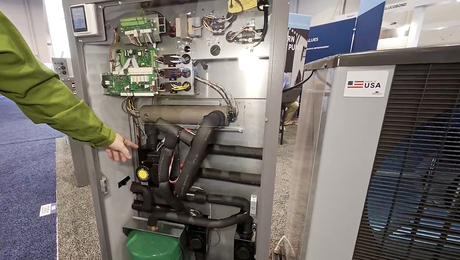

One of the buildings, dubbed the Baseline Home, “is typical of existing homes in the Inland Northwest” and will serve as a control, the PNNL explains on web pages devoted to the project. The other building, the Experimental Home, will be retrofitted to improve energy efficiency, lower the rate of water consumption, and improve the home’s indoor air quality. The first experiment will involve the installation of insulating (R-5) windows. The research also is expected to include evaluations of programmable appliances and car-charging stations, heat pump water heaters and energy efficient HVAC appliances, more insulation in the envelope, and installations of solar hot water and photovoltaic systems. Occupancy of both homes will be simulated.

A different set of comparisons in Tennessee

PNNL, a research arm of the Department of Energy, is not the only DOE entity studying residential energy efficiency. Oak Ridge National Laboratory, in Tennessee, the Tennessee Valley Authority, an East Tennessee builder, and an architectural firm in 2009 teamed up to form what is known as the Zero Energy Building Research Alliance, or ZERBRAlliance.

ZEBRAlliance’s principal project is a set of four 2,800-sq.-ft. model homes, each with a different envelope subsystem. One is constructed with structural insulated panels. Another features 2×6 studs, 24 in. on center, and OSB sheathing coated with a liquid-applied water-resistive barrier (WRB), R-21 flash and batt insulation (spray foam plus fiberglass batts), a TechShield radiant barrier in the attic, and R-49 cellulose insulation on the attic floor.

The exterior walls and attic floor of the third home feature cellulose-laced phase-change material and are covered with reflective Tyvek and a Delta-Dry dual-ventilated polyethylene membrane. The fourth home features a 4-in. exterior insulation finishing system and a trowel-applied WRB over 2×4 walls.

ZEBRAlliance celebrated the completion of the four homes, which offered similar amenities beyond their structural enhancements, in September 2010. Data collection on that project continues.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Great Stuff Foam Cleaner

Foam Gun

Staple Gun