Although it has been available to consumers since the mid-1990s, Aeroseal, a vinyl-polymer mist injected into duct systems to seal leaks, has caught on relatively slowly. By the end of 2001, for example, the technology had been used in 10,000 homes, and by the end of 2010 it had been used in 75,000.

That’s a lot of homes, but it’s still a relatively small percentage of those in the U.S. that could benefit from tighter ducts. The Department of Energy’s Lawrence Berkeley National Laboratory, which led development of the product, has in recent months begun trying to change that by highlighting the Aeroseal system’s virtues at a time when homeowners are increasingly looking for ways to reduce energy usage.

Aeroseal LLC, based in Centerville, Ohio, and licensed by LBNL in 1997 to deploy the technology, says the system can cut duct leakage by 90% and trim energy bills by as much as 40%. The best candidates for Aeroseal tend to be buildings that not only are unusually costly to heat and cool but also have unusually hot and cold rooms, are excessively dusty and humid, and are plagued by musty odors.

Straightforward application

Aeroseal says that duct leaks up to 5/8-in. wide can be sealed by the mist, a solution of water (65%), vinyl acetate polymer, and 2-ethyl-1 hexanol (the latter two compounds are considered nontoxic by the Occupational Safety and Health Administration).

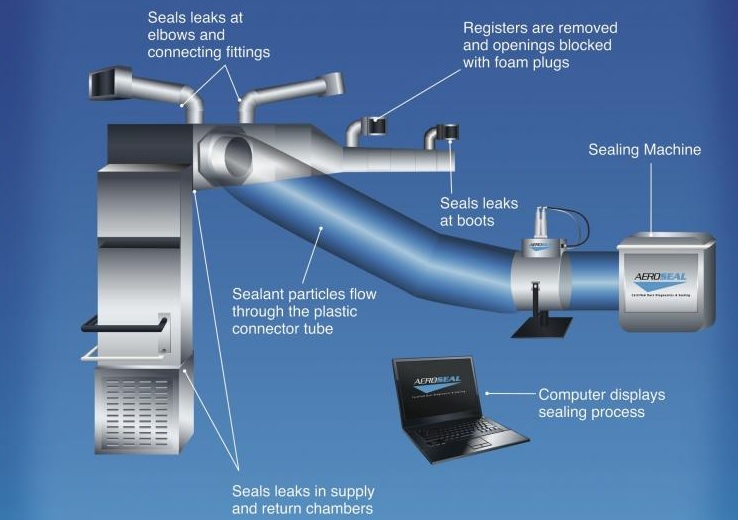

The baseline leakage of the client’s duct system is measured by forcing air into the system after its registers, fans, and grilles have been blocked off. The Aeroseal mist is then injected into the ducts, whose leaks close up as the vinyl polymer, under constant air pressure, accumulates around holes and cracks. The process takes 4 to 8 hours, according to the company, and the sealant is effective for at least 10 years, with no off-gassing.

In a press release about the technology, LBNL points out that in 2002 the DOE named Aeroseal as one of the 23 most influential products available to consumers. The system also has been used in commercial buildings since 2004.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Affordable IR Camera

Reliable Crimp Connectors

8067 All-Weather Flashing Tape

Adhesive particles of Aeroseal sealant are injected into a duct system after its openings to furnaces, fans, and grilles are blocked.

View Comments

Hey Richard, thanks for helping spread the word about Aeroseal. As the DOE article points out, this technology is a real game changer for energy conservation. There is a link on http://www.aeroseal.com to third party research that shows sealing duct leaks to be the single most effective thing many home owners/ builders can do to increase energy efficiency - more than upgrading windows, insulating wall cavities and sealing home air leaks combined - yet few people even consider air duct sealing when looking at energy-saving options. With folks like the DOE and Fine Homebuilding spreading the word, this is beginning to change - and none to soon. With Energy Star 3.0 for Houses kicking in full force come January 1st, specifications for air duct leakage becomes more stringent than ever - and while I must acknowledge my impartiality here (I work with Aeroseal), there really is no way to meet these new specifications without some type of aerosol-applied solution - and that is aeroseal technology. Here's to a successful year for all home builders in 2012!

Another way to improve energy efficiency is to install thermally broken windows and glass doors in your home. At http://www.heritagewindows.com, we also use aluminum framing on all of our doors and windows. Aluminum is 100% recyclable and affordable.

Energy is only part of the home security. Sealing off air infiltration is also important. http://www.energysavers.gov/tips/air_leaks.cfm details the sources of air leaks (and therefore energy leaks as well). The chart shows that the fireplace accounts for fourteen per cent of the typical home leakage, and the windows about ten percent. However the website gives no indication of actually covering the chimney top itself but only closing the damper. Many dampers are faulty or inoperable. They also warp over time which further renders them ineffective at controlling energy leaks. Warm air seeks the highest point of the home and creates the pressure on windows and other leakage points to provide make up air as energy zooms out the house top. Sealing off the chimney top is far less expensive than new windows and may lesson or eliminate the need to replace them. Visit controlcover.com for examples of this sort of energy saving solution.