Never Be Short of Shims Again

Make a custom cutting sled to ensure you always have an abundance of precisely-sized shims.

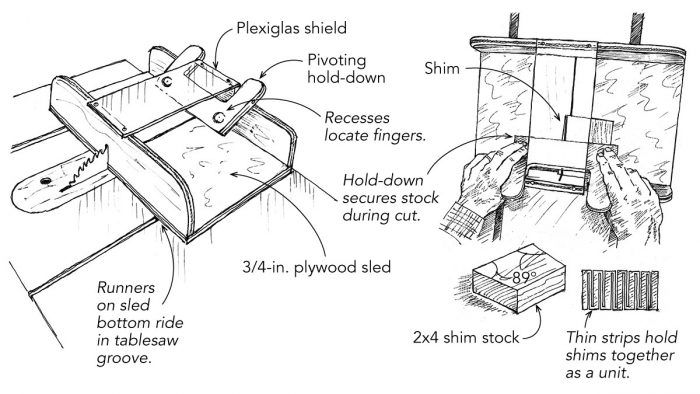

I got tired of never having enough shims on a job site, so figured out how to cut shims using a cutting sled that I designed and now keep in the truck. It’s really just a crosscut sled with a wide, pivoting hold-down that protects my hands and firmly holds the thin strips of wood that I’m ripping. As shown in the drawing, I added a Plexiglass shield for protection and some shallow circular recesses cut with a Forstner bit so that I always know where my fingers should be.

To make shims, I take a scrap of 2×4 about 3 in. long, and I make 89° cuts on each end. These end-grain cuts bear against the sled as the blade passes through the stock. With the blade raised enough to pass all the way through the stock, I can either cut individual shims, or I can lower the blade so that it leaves just enough stock to hold the shims together in a block until I’m done cutting. Just line up each cut with the kerf in the sled, and flip the 2×4 after each cut. You’ll never be short of shims again, and they taper to nothing (which is better than commercial shims).

— Jeff Mozer, Stanton, KY

From Fine Homebuilding #226

RELATED STORIES

Got a Tip?

Do you have any great tips like this one on how to cut shims quickly and efficiently? Share your methods, tricks, and jigs with other readers. Tag them @FineHomebuilding on social, email them to us at [email protected], or upload them to FineHomebuilding.com/reader-tips. We’ll pay for any we publish.