If you’re finishing pieces of woodwork with paint or varnish, you could just lean them up against the wall and hope that they don’t drip, but there’s a better way.

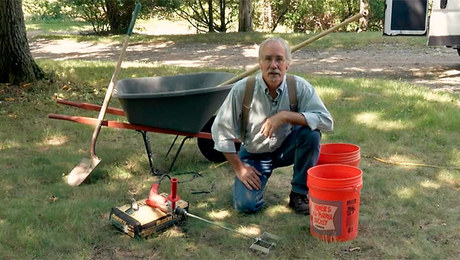

Dan Meyers from Olympia, Wash., starts by making a little A-frame, all made out of scrap materials. There’s a 2×4 base, and a 2×2 A-frame, with 2×2 horizontal arms which can be configured any way you want, depending on what your workpieces are. Then he uses scrap pieces of plywood–it doesn’t matter how thick the are–as the surfaces upon which he’s going to rest his workpieces. Now the key to this is all of these staples that he fires through the underside of each one of the little shelves. It doesn’t matter how thick the plywood is, so long as the staples protrude at the same length. The staples make a bed of little tiny points that allows for plenty of airflow under the workpiece and doesnt’ leave any marks as the work dries. It’s a great idea, it uses up scrap material, and it gets it all in one place–not leaning against the wall where it’s in the way.

great tip, Dan. Thank you.

View Comments

Can u do another April fools style tip this year? Last years was awesome and had me in years. I wondered how many people grinded down there hammer claws?

Has anyone had success trying this—laying a freshly painted surface UPSIDE-DOWN on sharp points and not have ANY resultant blemishes in the finish? If so, I have some swamp land down in Florida I’d like to sell you.

Dear Vegetable Gardener.

Please review tip again. It doesn't say to put the presentation side of the workpiece upside down. If we were spraying a cabinet door, for instance, the backside of the door would rest on the staple points.

cheers,

Chuck

As stars before Chuck, are you going to do another April fools video? I wanna see you top last years!

seems like a lotta work to me.

My drying rack is a 2x4 ripped into an octagonal and fit on 6 of the 8 faces with shelf standards,

Height is the same as my shop ceiling, and there's a little octagonal block on the ceiling to recieve it.

shelf supports let me put maybe 15-20 doors per support, stores in a corner, with a bucket to hold shelf supports. modifiable to site if needed. up and down in minutes. will hold doors up to 30" wide, and with judicious placement up to 4 or 5 ' height. Much more flexible, and once made, saves more time and space than this suggestion. Way less floor footprint as well!!

Eric

Hey Cowtown,

sounds interesting. Please send some pix.

Chuck