Winds of change: CNC fabrication of complex roof assemblies is seen by some as a step forward in custom framing

Not even The Digital Jobsite where “… the weather’s great…” is immune to the Winds of Change. In fact, they blow constantly as changes in technology expand capabilities for the building trades. Over time, traditional on-site carpentry tasks were phased out as pre-hung windows and doors, factory made millwork, cabinetry and custom stairs became the primary means for meeting ever-changing project requirements of design, schedule and cost.

The recent blog post by Scott G on 3D House Printing is an example of the sort of change on the horizon as various factors accumulate to make such radical changes practical, and in many cases, necessary. As computing power increases, CNC machines and CAD/CAM software become more capable, architectural design becomes more demanding, building codes become more restrictive, labor and materials increase in cost all while client expectations rise, contractors must adapt to stay competitive.

Perfect Storm:

The same factors that brought developments mentioned above gave rise to the roof and floor truss industry. Some project requirements that simply cannot be met with conventional carpentry/framing methods are accomplished with relative ease using engineered framing components. Complex configurations of roof geomentry, longer free-spans and more rigid construction are a few examples. Add to these schedule requirements and jobsite safety and you have a “perfect storm” gathering for digitized framing assemblies… I’m going to have to re-think the Digital Jobsite tagline if these foul weather analogies don’t cease.

Complex Framing Simplified:

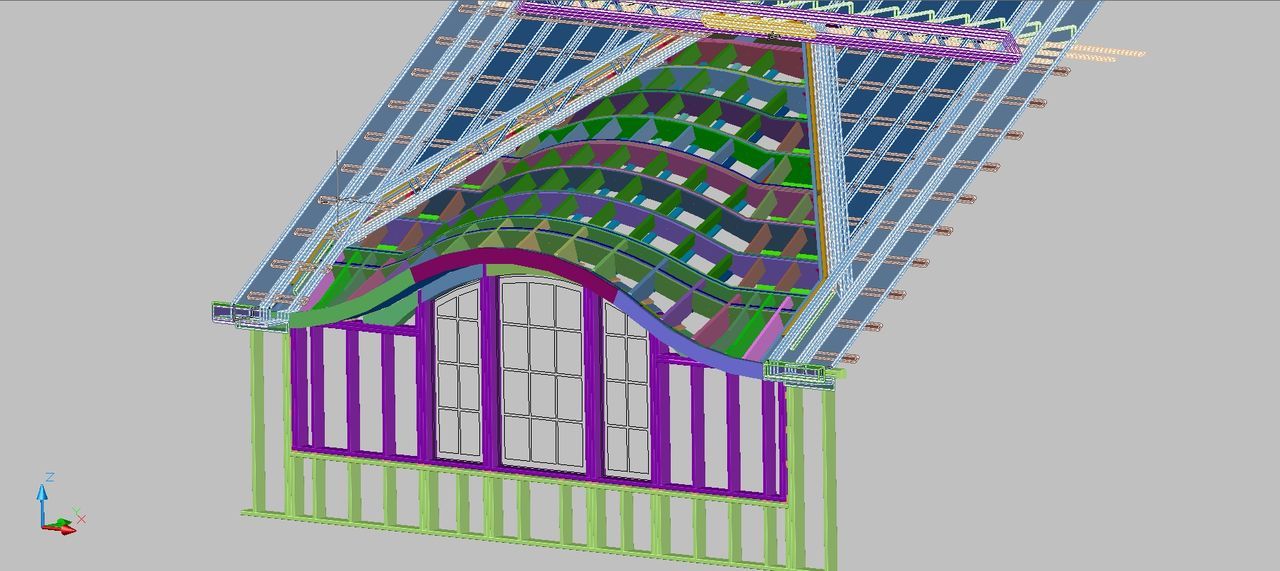

Recent dialog with Brent Green, project manager for DigiConSoo, inspired me to present what I see as the next wave of change. Using 3D models generated from 2D architectural plans and capable CNC machinery, DigiConSoo is a pioneer in this area of digital development.

This video gives an overview into the purpose, process and perks Brent and his team use to make complex framing simplified:

https://youtube.com/watch?v=1Prm46ld_jk

The Only Consistent Thing is Change:

Each new wave of change in the construction industry is met with resistance: 1x lumber for sheathing gave way to plywood, 2x12x16′ lumber gave way to floor trusses, roof trusses, I-joists, and LVLs. What about pre-hung doors and windows? I personally lived through the transition from site-hung to pre-hung doors and admit feeling a bit threatened by competition from a door shop that could do in hours what it took days to do on a jobsite. All these advances were ushered in despite a chorus of objections from keepers of the status quo. So it’s natural that digital CNC fabrication of complex framing assemblies, long reserved for elite tradesmen, draws some pushback from the trades with fears of becoming obsolete. And just as surely, before long, I predict we’ll hear “remember when we used to cut all this stuff on-site?” and “how did we ever get along before digtitzed framing came along?”. Imagine creating a structure with the design features of this Ruhl Walker Architects project on-site with present methods. There would likely be little longing for “the good old days”.

Is Digitized Framing Part of Fine Homebuilding?

Here’s why I think it is. Just because computers and CNC machines are involved it doesn’t mean that knowledge, skill and ability aren’t required. If the team at DigiConSoo were to mess up a .dxf file for CNC fabrication the result will be the same as if a journeyman carpenter miss-read his Riechers Rafter tables; lost time, money and materials. Both methods require experience, diligence and attention to detail which go into building a fine home. Craftsmen have always sought out and used the most current, effective tools to complete the project at hand, consistently raising the bar of what is possible. Isn’t that what fine homebuilding is all about?

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Musings of an Energy Nerd: Toward an Energy-Efficient Home

A House Needs to Breathe...Or Does It?: An Introduction to Building Science

Get Your House Right: Architectural Elements to Use & Avoid

View Comments

Really?

This is what our world needs? Another scheme to cut out the skilled worker and replace him with a machine because it's "cheaper" ?

The tradesmen who work on the kind of homes seen in the article have labored for years to get to the pinnacle of their craft, and instead of being grateful for their wisdom and experience, instead of appreciating the toil and sweat and study that makes up their livelihood and feeds their families , the aristocracy pushes that skill aside, colludes with the sleazy builder and the ivory tower architect to get it done without the "great unwashed".

Machines!!

The answer to all of our problems!!

The gulf widens every day between the rich and the poor, the edges crumbling into the abyss and taking the middle class with it.

But that's ok! The job gets done faster - there's no messy human interaction to spoil our day or make us feel something. We can just get Halliburton to bring in their giant 3d goo extruder and have them ***t us out a house.

It may be faster, it may even be more precise but that doesn't make it right.

People, not greed.

Soul, not machines.

Skill is about hands and heart.

This is not skill, it's blasphemy.

Not on my jobsite.

I met with Brent and Daniel, to see their operation. I found them to be very knowledgable, with extensive construction back rounds. My job, as a general contractor, is to give my client the best product. I will be using them to supply several details on my next project.

I met with Brent and Daniel, to see their operation. I found them to be very knowledgable, with extensive construction back rounds. My job, as a general contractor, is to give my client the best product. I will be using them to supply several details on my next project.

Neat article. I love the way technology is making things better. I remember trying to form an ellipse for a archway between 2 rooms. Tried the string method - failure. Then went online and watched several videos on other options and got it. I would have preferred to have just drawn it up in Google sketchup and then printed a template. For the trouble, I'd definitely pay these guys if I wanted something interesting. I think it's an excellent option for builders when they get a seldom used architectural element. Think about the man hours trying to figure out how to build an eyebrow dormer and you may not build another for years. I'd love to be able to say as a small builder that I could offer advanced architectural options like what is pictured above.

Rwaite: Seriously. It's just a tool. Do you make your own mullions and hand glazed windows? What poor customer can afford that? There are people at the companies that make these products. Just different people than the transient carpenter that shows up, works until he gets a paycheck then shows up high or drunk the next day. These might be geeks running the software and using CNC machines, but they're mouths to feed as well. I see this more as a way to offer the customer more. This isn't a pre-fab house company, it's a specialized company that offers some custom elements to help you offer more to your customers. Blasphemy is a poorly trained sub that runs his roofline so water runs to the house instead of away, or stacks his flashing backwards. Just because someone is poor doesn't mean he should be given a job where he can ruin someone's home.

I think it's fantastic! This is creativity, invention, and entrepreneurship - everything that made America great! When machines improve a product or make life easier the energies of creativity can focus on new and greater ideas! Way to go men - keep the spirit of America moving forward!!

@Steve -

You're telling me that you are not skilled enough to produce a quality product, so you have to outsource it. Why not invest a little bit in your skillset and some knowledge rather than sell out like this? You can try to say you have the best interests of your client in mind, but If you were capable of admitting it to yourself, you'd realize you were just taking the easy way out.

We're losing all of our skilled labor in this country, because people are lazy, greedy, and ignorant. Go take a course from someone like Billy Dillon if you don't know how to do something, or read a book. Improve your bank of knowledge and skill. You are part of the problem, you are turning the carpentry trade into factory work, and that will bring the wages down even more from the pitiful levels they are at today. The trades used to be a place where a person could work his way up as he grew in knowledge and experience to the point where he could make some decent money and get his slice of the American dream - you know, house, white picket pence, decent car to drive, raise a family, send the kids to college if that's what they wanted, retire to Florida and spend the days fishing. The standard of living is in hard decline in the trades, and it's because of this kind of disregard for anyone but yourself.

@Robwok -

We're not talking about windows. Let me clue you in, because you don't seem to be getting it - it's not about geek's mouths to feed or carpenter's mouths to feed, there isn't a choice. This kind of lazy crap will bring down wages to where nobody can afford to eat. Why do you think the job sites are full of illegals today? Because the constant demand for cheaper labor has led to drywall over plaster, ashphalt shingles over slate, vinyl siding over wood, plastic trim, fake "stone" and on and on. All of this garbage came about at the expense of skilled tradesmen - plastering was a skill, drywall is a factory job. Roofing with slate was an art. Asphalt roofing? Pays McDonald's wages, because the skill required to install it is about the same as the skill required to say "want fries with that?" Etc., etc.

High or drunk? If you have that on your site, it proves my point - that's all you can get for the wages you pay. Want better people? Allow them to advance, let them learn, pay them better. Don't put plastic garbage on your houses. Let your guys have some pride and dignity. When you bring this prefab crap onto the job, what you are rally telling them is " you aren't good enough to be a real carpenter, and I don't want to pay for you to learn anything, because money is more important to me than you are". No wonder guys show up drunk.

It used to be that necessity was the mother of invention. Now it's greed.

@rWaite. you sound like a Uion guy... You probably don't want tech like this since there's not a Lcal CNC Programmers 209 that can pay some union dues. Maybe that's part of the cost savings here, no union overhead to waste everyone's time through "negotiations" designed to sip money off the top.

This is a capitalist society. If the customer wants to pay half the amount for a well designed, CNC built dormer, then someone is going to supply it. You want to sell a hand made dormer at twice the cost, then you'll need to spend more time in marketing. There's plenty of people that like "hand made". Ferrari owners are some. I hear there are Italian shoes that are over $600. Suits over $5,000. We're not talking about getting rid of hand work, it's about bringing some architectural features that the avereage Joe can't afford and putting it on his house. What decade do you want to go back to? the 50's, pre computer? Maybe pre-industrial so there were more people using their hands? Luddite. Go look it up in your hand-scribed dictionary. Oh wait, I see you are putting your comments on a computer. Apparentely you're okay with some technology, just not the kind that affects your job. Maybe you're just reaching out due to a concern over your own inadequacy to keep up with the market changes. Go support your local therapist.

@rWaite - when I first read your comment I seriously thought it was just a really abstract attempt at sarcastic humor. Certainly nobody could be this ignorant. Actually, as sarcasm, it was quite subtle and clever - a guy using a computer to riducule advancements in technology that make things better and cheaper. Very funny.

Now that I see you are serious (although I still find that hard to fathom), I ask the same question - How could anybody be so ignorant? You actually think it helps society to do things less efficiently, more wastefully, and more expensively, just so that somebody who can't keep up with advancing civilization can feel good about what he does? And someone should pay more than they have to for a value that is not there?

What these guys are doing is advancing the possibilities, creativity, and productivity of the buidling industry. It's very exciting and opens up all kinds of possibilities for builders, architects, developers, homeowners and craftsman who would rather put their talents to use on new and exciting ideas that hacking out things the hard way. You don't think it takes skill to do what they are doing? Just because they aren't working in a cave with a hammer and chisel like you doesn't mean they aren't skilled.

And by the way - I was unaware that Halliburton had such a machine (3D goo extruder) as you describe. I know of about a billion and a half homeless people around the world that would be glad to have such a Halliburton Home, even if it wasn't crafted by your loving hands.

@robwok

Are you anti-union? I never said anything about my union status. Why bring that up?

I know it's a capitalist society. And fundamentally, capitalism is driven in large part by "what can I get at the expense of others?"

You bringing up computers is a ridiculous argument. Computers did not exist at all until very recently. Framing homes is a traditional craft that has remained more or less constant for centuries. It's clear that computer technology as a whole has created more jobs than it has destroyed, so I guess you can consider that a net plus on your morality scale.

Technology is moving so fast now that it has reached the point where it only divides us into classes.

In other words, Joe Framer is not going to be able to afford the CNC machines or the education to do what these guys are doing. The only ones who can afford it are those who have already won life's lottery. So what happens to him and his family? Lower wages, dead end job, no advancement. I'm sure you'll say he can retrain, but (1) he doesn't have the money for that, and (2) if he does, by the time he gets retraining for some other thing, technology will have made that "obsolete" too. That's why I said the gulf between rich and poor is widening.

No one needs this - somehow we've been doing just fine without it. If you have a house to frame, you can get a good carpenter to frame it, and I just can't believe that the savings from this is worth the livelihoods of decent people. Your'e fine with turning everyone into tract home builders? Because apparently skill in the trades is something people are working hard to make irrelevant.

And whatever savings there is, where does that go? In the pockets of those that don't need it. And where does it come from? From the pockets of those who can not afford it. Sounds like the rich taking from the poor to me. There's your capitalism. I'm sure that you're one of the people trying not to extend basic health care coverage to those people at the bottom, while crusading for this kind of thing that makes them less able to afford it.

@Skibum

You really think Halliburton cares about the homeless? I don't know who has the 3d thing - I saw it in the article. Halliburton was a metaphor - but if there's money to be made on it they'll be involved.They're not going to be giving away houses, they're just going to shoot them out as fast as they can so they can rake in the cash. If you want to help the homeless, go donate to Hbitat for Humanity. They still use carpenters. I don't think you brought that up because you care about the homelss, I think you're ok with using them to try (fail) to make a point.

As far as skill goes, you can't tell me that it takes the same amount of skill to use the computer for this than it does to use your brain .That's why they call it a computer - it computes FOR YOU. They're talking about home building like printing. How much skill do you use when you PRESS PRINT!!!!!

@RWaite

I have been doing this for 30 years. I work in an area where we build very custom beach homes. I have paid my dues. Framed many eyebrows, bells, arches etc.

I have also side wall shingled and trimmed them, inside and out. I am very proud of the work I have done.

I also continue my education by reading fine homebuilding, books, attending seminars, OSHA safety classes and building science courses.

I took my framer with me to see Digiconsoo's shop. He loved the idea of using these components to speed the job and make it more precise. Another point he brought up was safety and compliance. OSHA makes frequent stops in our area. We do try to be as compliant as possible but a lot of that is interpretive. His point was that instead of have 4 guys on the roof for 6 weeks framing these components, he will have 3 guys on the roof for 1 day to set them with a crane. Some of the items can even be roofed on the ground.

The people that work at Digiconsoo also have families as well as the truck driver that delivers the components and the crane operator. My framer will finish up my job and be on to the next that much faster. I would put the wages of myself, my workers and subs in the top 10% for residential construction in the country. The American Dream is alive and well.

A difference of opinion is something we may all learn from.

Attacking someones character, on the internet, shows your ignorance.

It is great to see an article from FHB about using modern technology to optimize the construction of homes. There is a huge pool of talented designers who model everything from fighter jets to your cell phone with 3D computer technology. I am actually surprised that architects haven't embraced full 3D designs and how they integrate with the construction process to make the coolest houses possible for the owners budget.

@RWaite...sorry, you can't stop time...btw, when was the last time you had your work truck re-shoed at the blacksmith?...jk.

@The architect who design houses in 2D...lookout!

@ Steve

You say you've worked your way into the top 10%, but now that you're "on top", you are ok with maximizing your income, and to hell with everyone else?

If you are tired of working, why don't you give one of the younger guys on the crew an opportunity to learn something, they'd like the opportunities you had.

Same goes for your framer - instead of getting all excited because now he can cram more jobs in and make more money ( it's never enough, is it) he should give one of his guys an opportunity to learn and advance. If the prefab garbage gets a foothold, where do these guys go? Nowhere - they remain laborers for life. And the OSHA thing is a red herring. I hear other contractors complain all the time about OSHA, building inspectors, permits, zoning or whatever. These things are in place to level the field and prevent people taking advantage of others. Would you prefer no rules, free-for all wild west style home building? How about this - invest in some equipment, training, have some safety meetings instead of trying these shortcuts to get around the system so you can put a few more dollars in your pocket.

I notice nobody is responding to the points, I guess that's because there's no argument for this other than ME ME ME.

@ rwaite.

You seem to be in the minority here. Possibly because the other "master craftsmen" that feel like you do, don't like computers. Though whenever I drive by a jobsite near lunch time, every guy has a sandwich in one hand and is texting with the other. (the younger ones anyway)

Maybe that's a signal. Cell phones were out of reach financially when the technology first came about, and now they're ubiquitous. (oh, and yes, I'm anti-union. I'm anti socialism as well - it feels like you're the type to vote against a technology just because it's "unfair" to the uneducated)

I will say that I hate the throw away society we have. Plastic houses and the habit of bulldozing houses for the sole purpose of replacing them with a McMansion. However, I don't see the technology in this article doing so. This wasn't about a house made by Haliburton. This was about a framing technique that makes it cheaper and more accurate to execute a difficult framing job for some framers. There's a lot of fearmongering in your comments.

The guys from DigiConSoo are skilled craftsman who took their trade to the next level. What they do is about precision, cost saving is a bonus. If someone can deliver in a few hours, what would take a crew of "skilled craftsmen" a few weeks to accomplish onsite, then who has the "skill"? They deliver a better product, faster. This is what I am looking for as a builder. If that makes me part of some evil empire set out to ruin the lives of tradesmen around the country then call me the EPA. Buying products that are designed, fabricated, and installed in the USA is a good thing, and I will continue to do that. This is not destroying the American dream, its just the opposite. These guys figured out a way to deliver a more precise product on a better schedule. They took off their tool belts and got off the roof to do so. Someone must have "allowed them to advance" and RWaite is calling them out for it. Maybe we should stop using air compressors and nail guns so he can keep up!

Great job DigiConSoo, can't wait for the next project.

I'm about done here, I'm getting tired of making valid points that no one responds to, instead coming up with new and novel ways to look down their noses at the lowly tradesperson and justify it with a fistful of dollars.

One last shot.

This will absolutely lead to decreased opportunities and wages for carpenters/framers. Does that enter into any decision on whether or not to go down this road? It does for me. If it doesn't for you, we have no common frame of reference, as I believe that we should collectively consider the consequences of our decisions as they affect other people.

This will cause custom home building to sink to the same level as tract home building. The only opportunity for creativity, the honing of skills, the opportunity to learn, the pride of taking on a complicated detail and being able to point to it with pride, is in custom homes. Tract houses are factory work, and pays sweatshop wages, because there is nothing there to challenge a skilled craftsman. If you take away those aspects of the custom home, and relegate them to computers and machines, custom homes will become bigger tract houses.

The only people to benefit from this are the people who need it least. The moneyed homeowner building the custom home, the GC who "manages" the job (come down from your lofty perch, put on a toolbelt once in a while), the factory owner, the architect too self-important to draft a pedestrian framing detail. These people aren't wondering how the next grocery bill will get paid.

There will not be same pride of work in a factory made assembly. Please don't try and tell me that the minimum wage factory assembler is going to care about the finished product in the same way as a conscientous tradesperson. Ever hear the cliche, "don't buy a car made on a Monday or a Friday?" In addition, factory workers are not carpenters, they just assemble parts the machine spits out. When some ugly monstrosity rolls down the assembly line, do you think they're going to look at it with the critical eye of experience and say, "you know, this just doesn't look right, let's see if we can't tweak this or change that." Nope - it'll be "faster, faster, get this crap loaded and out of here"

It may be intangible, but an assembly line can not impart "soul" to a project like a proud craftsman. I don't want my home to look like a machine built it, and I'm hoping that neither do others. Unnatural CNC "perfection" imparts a sterile, cold feel, as opposed to the warmth that a carpenter's skilled hands bring to a home. Think this is hooey? Not in touch with a little bit of your feminine side? Ask yourself, would I rather have a beautiful handmade piece of furniture by Tage Frid or Sam Maloof, or a "craplica" spit out of a machine and assembled in China? The soul of a home is a real thing.

This is a real morale killer for your jobsite. Think back to when you were a young buck , chomping at the bit to build your first set of stairs, or your first hip roof. Imagine if you went home at night and read every Fine Homebuilding article you could find about it, you asked the older guys for pointers and help, you bought the latest gee-whiz gizmo and laser guided sawzall that was going to help you build something you could be proud of. The big day arrives - the day you are going to ask the boss to let you build it, the time is right and you're confident you can do it. Imagine this is the response. "We don't do that anymore, I buy everything prefab from a factory. I saved fourteen thousand dollars last year over doing it on site!! Now get back to cutting blocking. And when you're done with that, my new truck needs a wash and wax." Bad morale = bad work.

If you would like to respond to these points, great!

If you would like to talk about the tires on my truck, the amazing paradox of my computer literacy or complain about the government, then we can safely assume you are trying to drown out your conscience. Keep it to yourself, ain't nobody buyin' today.

Good article and great exposure for this methodology. I own and use the same equipment as Digiconsoo. In my opinion, Cnc routers are almost jobsite portable. You have to look at it like you are using a table saw to cut a sheet of plywood except you calculate and record all the times you will move the fence beforehand. enter that data (cut list) into the computer and let it move the fence and cut the sheet up. It really is a big power tool that cuts wood. i have seen them on jobsites already but brought in its own cargo container. Not quite as easy as in the back of the Silverado but it will be soon.

Cutting sheet goods aside, we cut all kinds of architectural stuff on our Shopbot from dimensional lumber. A bunch of neat fences and gates from pressure treated pine and 8/4 Spanish Cedar, to cabinet boxes , doors, drawers and wainscoting. even 2x6's for stud walls. Charleston Fab Lab ifanyone cares to see how we do it.

Good article, I'm lovin' this discussion too! I especially like how the guy screamin' at everyone for missing the point seems to be the one missing the point here.

I am one of those design+build guys so I spend part of my time at the computer and part of my time shooting nails on the jobsite (actually I am a one-man-crew so I also spend time as the accountant, salesman, estimator, gopher, etc). Call me paradoxical or call me hypocritical I don't care but I love things handcrafted the same as I love things made by CNC. I consider both to be skills in my toolbox and knowing which one to use and when is the important key.

For example I fancy myself as a skilled cabinetmaker but that doesn't stop me from purchasing production made cabinets on many jobs. I know how to frame roofs of many types but I choose to use production made trusses on most of my jobs; I also don't normally fire my own tile on site nor make my own nails (although I have done both before).

As "owner/operator" of my own little business I work on contract 99% of the time (I can tell that RWait is hourly). For those of you who don't know and haven't yet rationalized it yet, being a contract laborer means I agree to a price that is cheap enough to get the client to choose me over the next guy and high enough that I should make a decent wage if everything goes right (note: I am not wealthy; everything never goes right). Therefore for every hour it takes me to complete a job I am actually making LESS dollars per hour. In contrast those union carpenters/wage workers make MORE money every hour and in fact if they work long enough stand a chance to 1.5X or even double their hourly earnings so of course they are in favor of less efficiency.

Another point of note is that my carpentry reputation is such that contractors tend to call me in to perform complicated and experienced tasks such as eyebrow framing, complex stairs, custom trimwork, etc. which I tend to do onsite with portable power tools. But what would be so wrong if I bought a CNC machine and did the exact same thing (onsite or in my woodshop)? I doesn't seem that much would change I would get paid the same except I wouldn't be dangling from a roof all day or sticking my fingers near a spinning blade so that would be a plus.

The reality is THIS IS HAPPENING. Like it, love it or hate it doesn't matter. Run away from change and you will fall down possibly never to get back up. Accept change and you may progress with it. Put it in your toolbox and it may help you out one day.

DC

@Dreamcatcher

Wrong, not hourly. I run a small general contracting company, same as you.

You and robwack think stereotyping is a substitute for a coherent argument. It's not.

Your post was all about more money in YOUR pocket. My arguments against this were all about the collective good. I care about the guys who work for me. Read my post again, and this time try to look at things from those starting out in the industry.

This is simple. If something can be fabricated better than site built then why would you not take advantage of it. It is not always about money. I buy shop made stairs because they are built better, stronger, and have way more design possibilities than site made stairs. Also being able to have temp stairs longer lowers my chances of damaging the stairs during construction. Sometimes they can be installed after board and plaster. This is just smart building. These are still custom pieces, a far cry from an assembly line. To say that craftsmen who build and assemble parts cut on a CNC don't take any pride in their work is just foolish. And to say a CNC assembly has no "soul"? My soul is in perfection. I would put a shop made stair against any site built stair, any day! People have deficiencies, machines don't. If I am building a high-end custom home I want to deliver it with no imperfections.

Do you think architects, homeowners, and GCs don't have bills to pay? I don't understand your comment. I would assume that people worry about their on bills before they consider your bills. If I own a CNC router should I shut it off to ensure you have work tomorrow? What a ridiculous comment. Is it even serious. Everyone is trying to make a living at what they do, not consider how it affects your life. If that was how the world worked I would expect you as the "framer" to think of a way to make my life as a "GC" better. Oh wait a minute, DigiConSoo already did that, never mind.

Your furniture analogy is also ridiculous. You are IKEA in this situation. The eyebrow dormer these guys made is so far superior to what could be constructed onsite its not even close. Strength, accuracy, craftsmanship, fit, finish, etc...The only thing it didn't have was a cranky old carpenter complaining about technology stealing sandwiches from him.

You probably drive a Tundra

Whew. Just got back from being out of town installing a new kitchen. It was a real pain to have to teach that young fella how to hammer out a double stainless steel sink by hand. He complained saying that we could just get one from the local box store. I guess I could have let him start on copper, but the customer wanted stainless. I looked over the top of my metal lathe where I was tooling the faucet and just shot him a withering look. Our glass blower turning the lightbulbs just laughed.

These kids. They just don't understand.

Beautifully done