Meet the Timber Truss

To all those carpenters out there who insist on dead flat, completely straight, and nothing but plumb and level, Roald Gundersen has a message for you: Get over it.

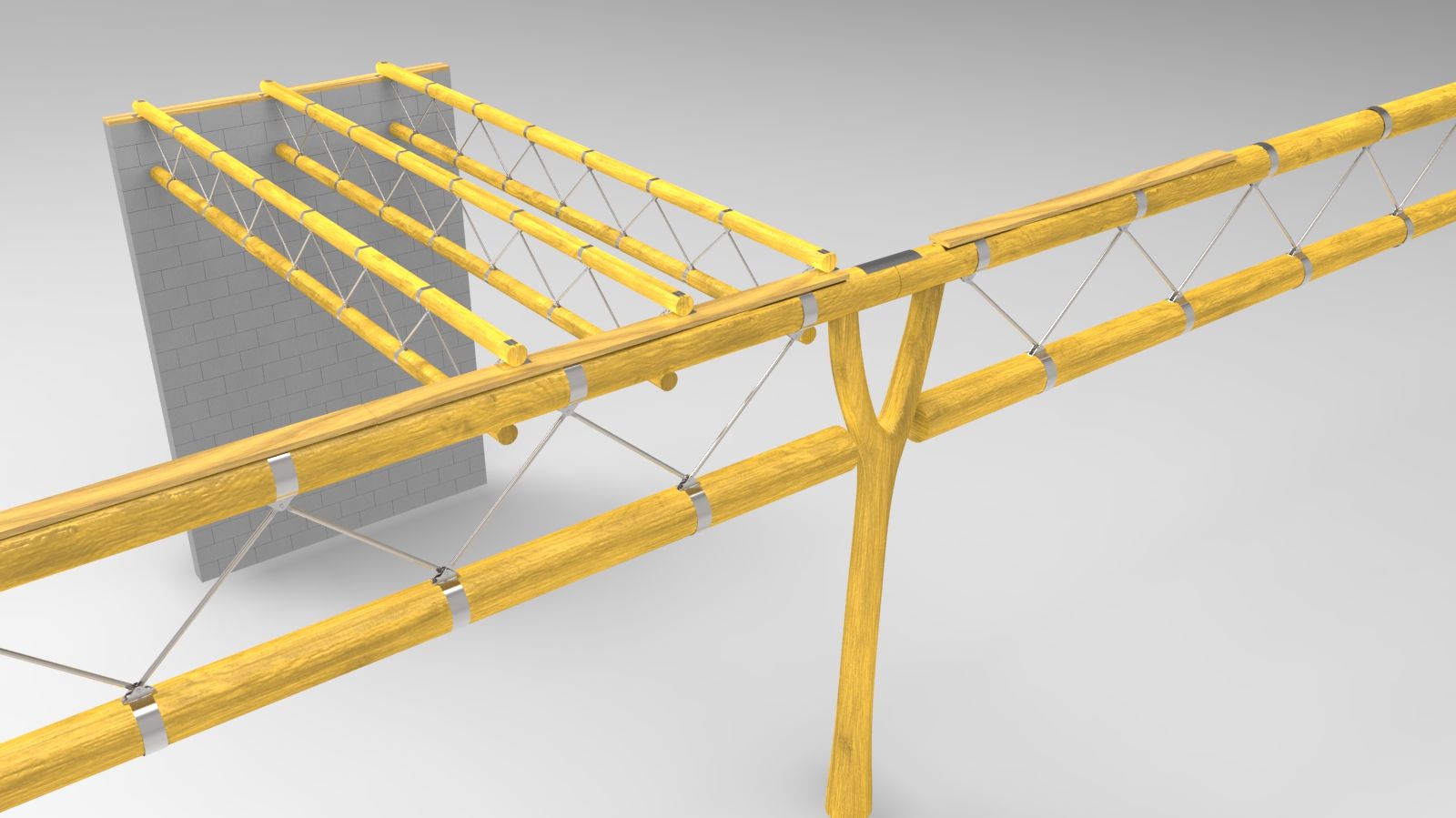

The architect and co-founder of Whole Trees Architecture and Structures in Stoddard, Wis., has been working for years to incorporate sections of whole trees into the buildings he designs; now his firm is producing floor and roof trusses made with round timbers.

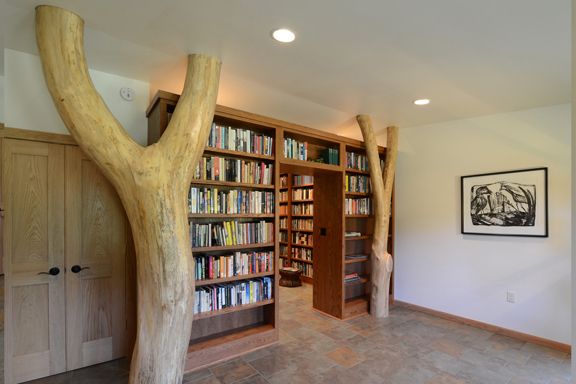

The organic, unregulated shapes of the ash, pine, and aspen trees he uses as structural columns give his structures a sense of playfulness as well as strength; owners feel as though they’re living in a tree house or a forest. But Gundersen and his partner Amelia Swan Baxter are after more than a trendy aesthetic.

Columns and trusses made with tree sections are substantially stronger than milled timber, and the wood is much more plentiful than what is now turned into conventional trusses.

“The round timber becomes incredibly efficient,” Gundersen says. “It has a comparable weight-to-strength ratio to steel.”

Now it’s just a question of producing more standardized products that will appeal to carpenters as well as homeowners and designers.

Not a seat-of-the-pants design effort

In 2010, Whole Trees won a small-business innovation grant from the U.S. Department of Agriculture. The company subsequently worked with the U.S. Forest Services Laboratory in Madison, Wis., to test the strength of tree parts, something that had apparently not been done before in a controlled setting.

At first, the company focused on ash trees, which are under attack in more than a dozen upper Midwestern and Eastern states and parts of Canada by an insect called the emerald ash borer. The bugs have killed millions of ash trees, but Gundersen learned that the structural qualities of the wood weren’t affected by infestation.

Researchers put branched sections of trees into heavy-duty presses and studied when and how they broke under pressure. Gundersen says one surprising result was that branched connections of tree parts turned out to be very strong–stronger, in fact, than other parts of the tree. He calls this “the evolutionary structural intelligence of the tree.”

“For the phrase ‘Trees are stronger than wood,’ it is not immediately obvious how that could be,” Gundersen said in a recent telephone interview. “But the end-process tree is 50% stronger in bending than a processed timber.”

Gundersen hopes the research will lead to more standardized timber components that resist gravity and seismic and wind loads better than conventional materials. Eventually, he thinks his whole-timber products can compete successfully with steel and concrete.

“Trees are big bones and very strong, and houses can definitely use that structural capacity,” he said.

The Whole Trees truss and column business, launched in 2007, did a million dollars of business last year.

Potential roadblocks in inspectors and builders

Gundersen acknowledges at least a couple of potential problems to overcome before the timber trusses become more widely used: acceptance by code officials and inspectors, and acceptance by carpenters who install the unusual components and have to build floor or roof systems on top of them.

Building inspectors are familiar with steel, concrete, manufactured trusses, and other standardized products, but not timber trusses. Gundersen says that Whole Trees “addresses their concerns early on” with results of testing that has been done to date.

As Gundersen and his team have learned more about the properties of timbers, they have come to suspect that early trusses were way overengineered. Gundersen says they’re trying now to engineer trusses with about twice the load-bearing capacity of the actual maximum load that’s anticipated, what he says is an industry standard for wood components.

Most carpenters prize uniformity in the materials they’re using. They want straight studs and joists that make straight walls and flat floors. So what do they do when using floor or roof trusses that are made with tapered timbers that have never seen the inside of a sawmill? Some irregularities are all but guaranteed.

One technique Whole Tree installers have used on floors is to get trusses to within about 1 1/2 in. of level by judiciously trimming and flattening some of the timbers. Then they install light steel decking and concrete. The steel conforms to the irregularities in the floor, Gundersen says, and the concrete can be leveled on the top. The concrete can be left as the finish floor or covered in another material–wood or carpet, for example.

Finished ceiling materials can be something flexible, Gundersen says, such as canvas.

At the moment, Whole Trees installs all of its own trusses, but Gundersen says that as the products become more standardized, he imagines ordinary carpenters would be able to install them with only a little extra effort.

The bottom line for Gundersen, however, is that not every surface of a building has to be level or plumb. Curved forms, both in nature and in man-made structures, are much stronger than rectilinear shapes, and they’re better at resisting earthquakes and strong winds.

Plus, there’s the enjoyment people find in living with curved shapes that haven’t been machined and milled into perfect uniformity.

“Every material you put into a building has been through a machine,” he says, “and this one will be an exception, one of very few exceptions. Because of that, it doesn’t fit into that box, so to speak, for a visual point of view.”

Benefits for the forest

One advantage of using whole timbers for columns and truss flanges is the sheer volume of material that’s available for use. Manufactured trusses need sawn lumber of relatively high quality, but Whole Trees can make trusses from wood that may not be commercially useful for anything else–for example, wind-damaged trees or trees infested by insects such as the emerald ash borer.

As high-quality logs become scarcer, Gundersen thinks his approach will look more attractive. Trusses and columns can be made much closer to where they will be used, he says, with far less embodied energy than milled and manufactured components.

“We take the worst first,” he says. “The resource base can be, by my estimates, somewhere between 50 times and 100 times as big. It’s an enormously more abundant material than millable logs.”

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Affordable IR Camera

Handy Heat Gun

Reliable Crimp Connectors

View Comments

Thanks Scott for the interesting article. Old homes and buildings in Europe built during the 16th and 17th century include walls built with complete logs and branched connections -- mixed with standard post-and-beam. Space between the timbers was filled in a variety of ways with wattle and daub, rock and rubble, brick, packed earth etc. Modern renovations often expose these irregular beams, allowing the rough wood to show through new plaster.

The visible sections in these walls are not as long or elaborate as the Whole Tree designs, which turn the old "use what is available" into an art form.

Neat! Thanks to Gunderson and Baxter for persistently pursuing such a difficult design solution. An important translation to remember is that of "efficiency." Implicit in efficiency is that the material's greater unit strength can be successfully directed into fewer units and therefore fewer joints/installations that offset more complicated unit installations.

As a CA and IPD specialist, I look forward to the collaborative efforts that such an organic approach will require, and I think this is the heart of the solution: Builders need to know that the designers won't abandon them in these type of designs, designers need to know that they can depend on the builders to faithfully guide the constructibility of their design efforts. Many builders who are churners and burners will decry this approach, but those who find joy in the craft should revel in the skills and challenges that lie herein.

The root level (sorry for bad pun), basic nature of this leads me to suspect that certain situations can be solved by good, ol' fashioned lathe-and-plaster, maybe rammed-earth, dimensional furring, and pure tensional lay-ups.

In building my dream house starting with a custom scribe fit log shell, I have incorporated many trees into the support structure of the exterior decks. Using black locust branched logs and mortise and tenon joinery, these support structures blend well with the character of the home. I've also used maple logs to support landings and stairwells inside the house. Incorporating these trees, 6 to 12 inches in diameter, from my property is aesthetically, financially and emotionally pleasing. An added benefit is black locust is more rot resistant than pressure treated.

So, are the risers and treads as casual as are the framing members, including the stringer?

I work in historic restoration and am always surprised by

the strength of riven wood compared to lumber that has been

milled. It follows that whole logs and branches would have

great strength.

Talk about natural innovation, wonderful. What are the best management practises re green wood which has most flexibility but drying wood and shrinkage will need thoughtful practises?

Thanks for article.

Cheers