We usually build custom homes, but recently, our crew had a different kind of job: replacing 5000 sq. ft. of vertical wood siding with fiber-cement siding on our local firehouse. My research led me to the problem that always comes up: dust. Cutting fiber-cement siding can produce clouds of dust, and I wanted us to breathe in as little of it as possible. This would not be easy, because we needed to make a lot of long rip cuts and angled crosscuts for field joints.

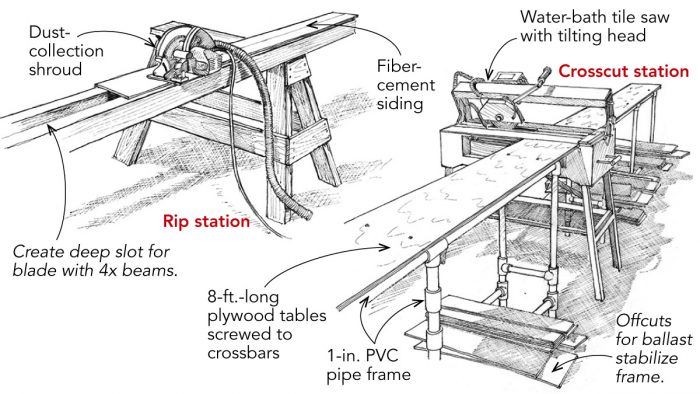

As shown in the drawing above right, we used a water-bath tile saw with a diamond blade that tilts up to 45° for the scarf joints. At about $275 from Amazon, the saw was fairly inexpensive. The saw is flanked by 8-ft.-long tables to support the siding during a cut. I wanted to move the cut station easily as we worked around the building, so I made the table supports out of lightweight 1-in. PVC pipe.

For ripping the material, we used a Makita circular saw with a dust-collection system. Its dust collection shroud does not float up and down with the blade-depth adjustment, so to take full advantage of the dust-collecting abilities, the blade needs to be set at full depth—hence, the 4-in.-deep slot between the rip station’s beams. With this saw hooked up to a vacuum and the operator wearing a full-face approved respirator, we were well protected.

Jim Docker, The Sea Ranch, CA

Edited and Illustrated by Charles Miller

From Fine Homebuilding #237