Pro Tips for Deck Refinishing

Use this foolproof strategy to rescue a worn, weather-beaten deck.

Keeping decks looking good in a sunbaked climate can be a challenge, but it provides me plenty of work as a professional deck refinisher. In San Diego, where I live and work, outdoor living space is important, and my clients expect a deck to look as good as the interior of a house. Maintaining a deck can be a huge challenge. Poorly handled cleaning or refinishing usually results in a deck that has to be redone.

I was recently called to look at a hardwood deck in Solana Beach, Calif. This deck, which was about three years old, needed a good cleaning and refinishing. In addition, black streaks emerged from every fastener on the stairs, the privacy fence, and the glass-paneled walls that protect deck occupants from coastal winds.

The stains resulted from the nails’ rusting. Apparently, the builder had used galvanized nails to fasten everything but the decking. I see this black staining regularly despite the sound advice of distributors who suggest stainless-steel fasteners for tropical hardwoods. Fortunately, the deck surface was unaffected because the decking was attached with blind fasteners (ebty.com).

Begin With a Thorough Cleaning

This project was typical of the deck-refinishing work my crew undertakes. First, we clean the wood with a concentrated detergent. Then we follow up with a wood brightener. After each step, we power wash using a wide-angle (40°) nozzle.

A pressure washer in the hands of a novice can destroy landscaping, force water into a house, and ruin a wood deck. We’ve handled many projects where homeowners or contractors have damaged the deck surface with a power washer. Fixing the resultant gouges requires extensive sanding and sometimes new decking. Before I let new employees touch someone’s deck with a pressure washer, I teach them how to feather the stream of water onto the surface when starting out and how to let the cleaning chemicals do the majority of the work. We always use a wide-angle nozzle on decking, even if it takes a little longer to get the surface clean.

On this deck, once the wood was cleaned and brightened, we turned to the rusting fasteners. To prevent water from getting into the nail holes and causing a recurrence of staining, we filled the holes with a wax-based exterior filler. We heated the filler slightly with a tea-light candle and carefully pushed it into the 400-plus holes. Minor sanding with a medium-grit sanding sponge removed the excess filler. We used a light touch, because excessive sanding can result in a noticeable change in the wood texture that shows up later when the deck is finished.

|

|

1. Spray on the cleaner. Starting with vertical surfaces and working from the top down, apply deck cleaner. Allow it to work for 10 to 15 minutes.

|

2. Scrub the surface. Moving in the direction of the wood grain, use a stiff-bristle brush on a telescopic pole to clean the wooden surfaces. Horizontal boards are usually the dirtiest. Use smaller handheld brushes for hard-to-reach areas.

3. Power rinse. Starting with the vertical surfaces and working from the top down, rinse the deck clean with a pressure washer equipped with a wide-angle (40°) nozzle. Nozzles with a tighter spray pattern can strip out soft areas, leaving gouges. |

Then Use Brightener to Make Old Wood Look New

3. Rinse clean. A gas-powered pressure washer equipped with a wide-angle (40°) nozzle rinses and cleans the surface without damage. The pressure washer doesn’t apply the two cleaning chemicals; it sprays only water.

|

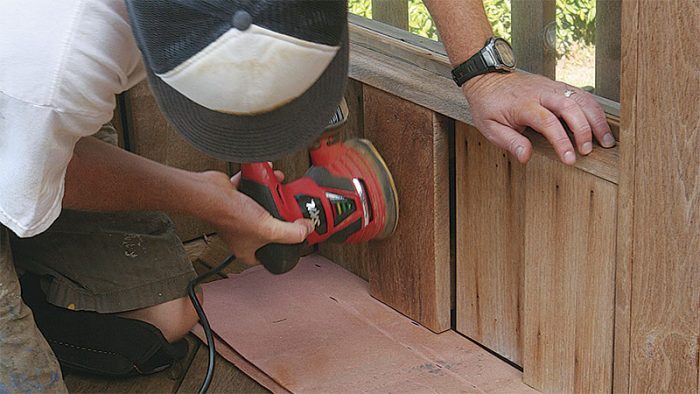

A Fix for Rusty FastenersDespite recommendations to use stainless-steel fasteners for hardwood decks, we often see decks built with galvanized fasteners. Unfortunately, it doesn’t take long for the nails to rust, leaving black streaks that can make an otherwise beautiful deck look really bad. In most cases, the cleaner and brightener remove the marks, but in some badly stained areas, only a sander can remove them. This is a last resort, however, because it means sanding the whole board or having a board with an inconsistent appearance between sanded and unsanded areas. Once the black marks are gone, we fill the holes with a color-matched, wax-based wood filler. It’s important to pick the right color, or the filled holes will be as obvious as the black stains. Sand away marks. In spots with the worst black staining, the cleaner and wood brightener are not fully effective at removing discoloration. In these spots, the only solution is to use a random-orbit sander equipped with 120-grit paper over the board. Fill and smooth. Once a matching color has been found, the wax filler (fastcap.com) is applied with a plastic spatula included with the kit. The same tool scrapes away the excess. |

Finally, Apply the Finish

With the surface clean and free of rust stains, it was time to apply the coating. Choosing a coating can be confusing to homeowners and contractors alike, and mistakes in application can result in serious problems, including peeling from improper adhesion, blotchiness from improper surface prep, or the use of too much finish. Usually, the coating has to be chemically removed and the deck recoated.

I’ve done my own testing on 50 products over the past 23 years and continue to test finishes. For this deck, I used an oil-based stain for hardwood decking from Superdeck (superdeck.com). This coating enhances the natural look of the wood with penetrating oils that protect the surface and prevent mildew and water damage. The high density of hardwood decking makes using the proper application method important. We use several different types of applicator pads and make long strokes to avoid leaving lap marks and applying too much coating. After the coating has fully penetrated (usually in 10 to 15 minutes), we use a lint-free cloth to remove the excess material.

For tight corners and other hard-to-reach areas, we use a natural-bristle brush and then wipe away the excess coating with a lint-free cloth. We also watch the amount of absorption, because the density of individual boards can vary. As a result, some boards need more finish than others.

3. Wipe off the excess. Once the finish has had a chance to be absorbed fully by the decking (10 min.), remove the excess with a rag (small areas) or a rag-covered scrub brush (large areas).

Tips for a better finish

|

Jim Grant is an outdoor wood-finishing expert from San Diego. Photos by Patrick McCombe.

Click the button below to download a full PDF of the article.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

4-Gallon Piston Backpack Sprayer

Standard Marking Chalk

Drill Driver/Impact Driver

View Comments

I have just laid a merban deck and there are Water stains

how do i get rid of them?