Less wood plus more insulation amounts to big savings

Advanced framing, also called optimum-value engineering (OVE), was developed decades ago as a way of saving materials and making more energy-efficient buildings, but many builders have been reluctant to adopt it. If you count yourself on that list but want to know more, APA–The Engineered Wood Association now offers an online video and a guide that can be downloaded for free.

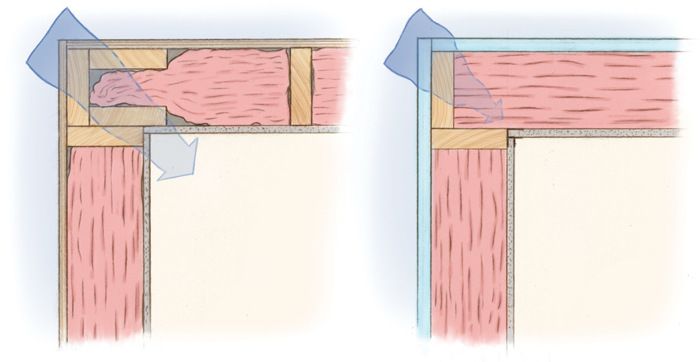

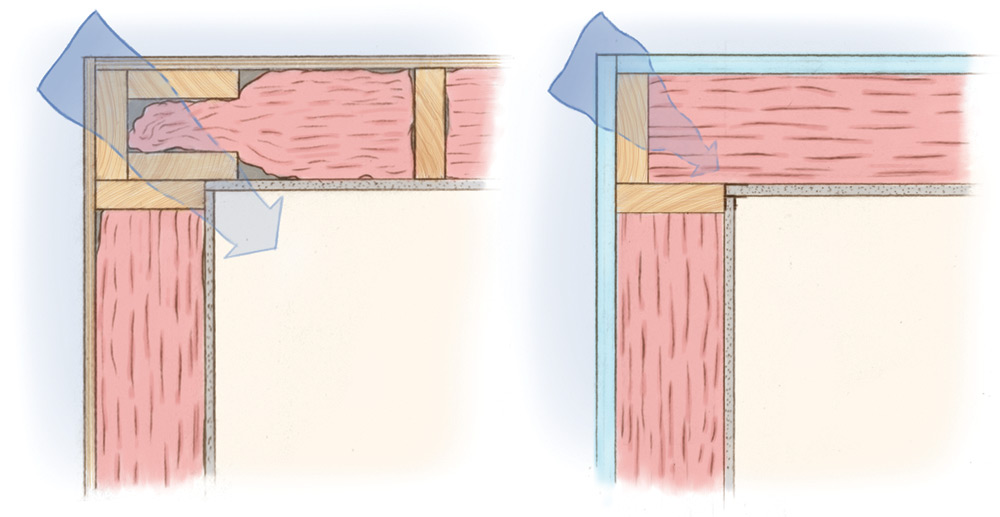

In the 4-1/2-minute video below, senior engineered wood specialist Bob Clark and product support specialist Merritt Kline discuss the basics of advanced framing and explain how it can help make wood-framed buildings more efficient by eliminating unnecessary and redundant framing members and leaving more room for cavity insulation.

If you want more information, vist the APA’s page on advanced framing where you can read about the basic concepts as well as download the free Advanced Framing Construction Guide. It covers a number of OVE techniques, including wall intersections, single headers, two-stud corners, and single top plates. The APA offers a printed version for $2.

The APA maintains a library of related material at its website.

More videos and articles on advanced framing:

|

|

|

| Video: Advanced vs. Traditional Framing Advanced Framing can get a bad rap for being too geeky for a traditional builder |

Bring Advanced Framing to Your Job Site |

The Future of Framing Is Here Smarter strategies can save money, speed construction, improve energy efficiency, and cut down on job-site waste |

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Reliable Crimp Connectors

8067 All-Weather Flashing Tape

Handy Heat Gun

View Comments

The right drawing is incorrect. You can't fix the board on the insulation only!!!!

The drawing on the right shows drywall clips in place of the 2x backer. These small metal clips attach the two pieces of drywall at the inside corner. One clip every two feet or so will create a solid inside corner. I started using this detail 20 years ago working for a custom homebuilder in Wisconsin. When drywall clips are not available a few small scraps of 1/2 osb or plywood attached to the inside of the single corner stud will give you a sheetrock backer and allow for near full insulation at the corner

Advanced framing sounds like using less lumber to me (disdain doublespeak). I appreciate the need to minimize thermal breaks in a wall, and even decouple framing members from exterior, which would be my first choice (exterior insulation underneath rainscreen). What it really comes down to is real world testing...does OVE stand up to seismic testing and load testing? We use neither corner framing illustrations on west coast (use California corner).

Would like to see 'traditional' vs OVE framing on a shake table before I go OVE.

Would likely have to spend more money on floor plate to wall to floor plate pinning? Instead of all that fuss, focus on exterior insulation where one can decouple the framing.

user-650508, the right drawing shows the drywall clips in place, thereby eliminating the need for a nailer.

OOPS, I see that rjgrandlake already mentioned the clips.

The information is pretty great! I have worked with Framing Contractors in Surrey and found it really helpful.