What’s the Difference: Bench Planes and Block Planes

Any decent woodshop is going to have a variety of hand planes, but these tools are far less common on a job site. Still, a hand plane may be just the right tool for those places in a house where wooden parts need to fit precisely, such as cabinets, doors, and trim. In these places, planes can smooth surfaces, remove minuscule amounts of material at a time, and clean up areas cut by other, less precise tools. In many places, planes can reduce or even eliminate the need for sanding. Moreover, because planes are much quieter than power tools, if you whistle while you work, you’ll be able to hear yourself.

Bench planes

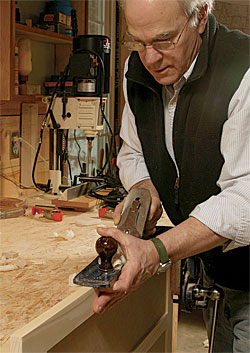

Bench planes are so called because they are most often used at a woodworking bench. They are held with two hands, with the front hand holding a knob and the back hand gripping a handle (called a tote). The blades on bench planes are angled at 45°, and they are positioned with the bevel side down. A chip breaker lies on top of the blade in a bench plane; it directs wood shavings up and away and helps to reduce the stuttering or skipping movement known as chatter.

To distinguish bench planes of different sizes, most manufacturers use a numbering system established in the 19th century. For an entry door that needs to be trimmed, or even a large cabinet door, the most useful bench plane is likely a no. 7 or no. 8 plane. These planes, known as jointers, have a long sole that allows them to create a flat surface over a long area. Jointer planes can get the job done quickly and evenly, although their size and cost may have you looking for an alternative. A no. 8 plane is 24 in. long, and a Lie-Nielsen model can cost almost $500.

If you frequently need to surface smaller areas, a smoothing plane (no. 4 and no. 4-1/2) or a jack plane (no. 5 and 5-1/4) may also come in handy. Senior editor Andy Engel has found that a no. 5 is generally an adequate job-site substitute for a jointer plane, and its length (14 in.) and cost ($325 for a Lie-Nielsen) make it easier to justify adding to your toolbox.

Block planes

At only 6 in. to 7 in. long, a block plane is designed to be used with one hand, and it can fit easily inside a tool pouch. For projects such as cabinets, these small planes have a variety of uses: chamfering, cutting end grain, leveling corner joints, trimming miters, cleaning up saw cuts, and smoothing straight and curved edges. Block planes are available in standard and low-angle versions.

The blade on a standard-angle block plane is set at 20°; the blade on a low-angle block plane is set at 12°, which is better for cutting end grain and adjusting miters. Because the blade angle on both of these models is much lower than that on a bench plane, chatter is naturally reduced; at the same time, the risk of tearout is greater. The reduction in chatter means that a chip breaker is unnecessary. As a result, the blade is positioned bevel side up, effectively increasing the blade angle and allowing the blade itself to direct shavings away.

If a carpenter has only one plane on a job site, it’s likely to be a standard-angle block plane. These handy little tools are useful for back-beveling miters, chamfering edges, scribe-fitting panels, and angling cedar shingles for woven corners. (No plane is worth using if it’s dull. For instructions on tuning up a block plane, see “Tune up a block plane,” FHB #234.)