Invisible Repairs to Hardwood Floors

The key is finding boards that match and installing them with care.

Synopsis: The beauty of a hardwood floor has an underside: It can be difficult to repair damaged boards and to do so in a way that integrates the new boards with the old. In this article from FHB‘s Project House series, restoration contractor Scott Sidler shares his process for making invisible repairs to hardwood floors. The first step is finding boards that are as close a match as possible to the existing floor. This means not only finding boards of the same species, but finding boards of the same width and with a similar grain and color. Sidler then demonstrates how to remove the damaged boards, how to patch an open or damaged area of the subfloor, and how to install new boards tightly, maintaining the tongue-and-groove connections and keeping face-nailing to a minimum. He concludes with tips for blending the new with the old when refinishing the entire floor is not in the budget.

Other than refinishing hardwood floors, the most common repair my restoration company gets called to do is floorboard replacement. The typical reasons we replace boards are termite or water damage, pet stains that blacken the boards to a point sanding won’t fix, and floor-plan changes that involve the removal of interior walls.

My goal is to find replacement boards that match the existing floor, and then integrate them for a natural appearance. It takes skill and patience, but the payoff is another 100 years or more of use without having to resort to an unfortunate solution: covering up the old floor with carpet, vinyl, or another layer of wood. The mark of success for a restoration carpenter is for nobody to realize you were ever there.

Identifying wood and its installation

When I get called to look at a floor-repair job, the first thing I check is the species of the wood. The old homes I come across here in Florida usually have flooring of heart pine, red oak, or white oak; occasionally, they have Douglas fir. There are online guides to identifying wood grains, but this part of the job is hard to teach. Experience really is the best teacher.

I can usually identify the species by examining the grain of the planks, and I know some people who can determine the species by the smell of the sawdust or the weight of the boards. When in doubt, I remove a couple of boards and bring them to the salvage yard for help in finding a match.

The second thing I look for is whether the joints of the floorboards are randomly spaced, or set consistently at 16 in. or 24 in. on center. Consistently spaced joints are usually an indication that there’s no subfloor under the hardwood flooring. In my area of Florida, this is common to the oldest homes (1890s and earlier) and the homes in the low-end working-class neighborhoods built from the 1900s to the 1940s.

If there is a subfloor, I can use the replacement boards more efficiently, staggering the joints wherever I need. Without a subfloor, I have to use lengths in 16-in. or 24-in. increments and be careful not to fall through the floor while I’m working on large repairs. Also, in homes without subfloors, the planks run underneath the interior walls instead of butting against them, which means far more hassle when it comes to removing and replacing each piece.

Finding the best match

When it comes to finding replacement boards that will blend with the rest of the floor, there are a few options. In the case of this project, we got lucky. The second floor of the house had been gutted by a previous owner, and the old flooring had been left behind, so we had a full stack of original floorboards to choose from. Without that, we would have had to start shopping around for a match.

Don’t expect to get a good match just by driving to the local supplier to pick up some new wood of the same species. Wood looks different depending on where it was grown, when it was harvested, and how it was milled. For the best match, check an architectural salvage yard. First, though, arm yourself with as much information about the existing floorboards as possible.

Start by taking careful measurements of the existing boards. The width needs to be pretty accurate for a good fit and a satisfying match. In my area, I’ve seen heart-pine boards in 2-1⁄4-in., 2-3⁄8-in., and 2-1⁄2-in. widths. Why manufacturers decided to have such minimal differences is beyond me, but they do make a difference, so measure carefully. Fortunately, this is a pretty easy measurement to take right from the finished surface of the floor.

Accuracy is less crucial for the thickness of repair boards; as long as you’re within 1⁄8 in. or so, the sanding should remedy any slight differences. That said, a replacement board that’s too thick is better than one that’s not thick enough.

To measure the thickness, you’ll need to get creative. I typically look for a floor grate or a piece of baseboard I can remove in order to get an accurate measurement of the cross section of the flooring.

Pay attention to the position of the tongue of the board, too. The tongue is right in the middle of most floorboards, but with 7⁄8-in.- or 1-in.-thick boards, the tongue can be just below center. (This allows the boards to be sanded and refinished more times before replacement is necessary.) You need enough thickness above the tongue to match the rest of the floor, but the more crucial dimension is the distance between the tongue and the bottom of the board.

Finally, you need to find an appropriate grain and color match. For instance, if the floorboards in the house are quartersawn, then a replacement board with flatsawn grain will stick out like a sore thumb. The same holds true when comparing heartwood with sapwood. Some heart-pine floors have a lot of deep-red heartwood, while others are a bit more yellow.

Before you begin searching salvage yards for a match, find out the date that the house was built. If the homeowner isn’t sure, check the property-appraiser’s website, or visit the town hall. Ideally, the replacement boards will be from the same decade. If a decade match is not possible, at least look for similar grain patterns. Should you find nothing but replacement boards that are close but not quite perfect, there’s still a back door. You can borrow flooring from a closet or pantry to do the more visible repair, and then put the new wood in these more remote locations where it will be less noticeable. It means more repair work, but the payoff is worth it.

Patching comes first

Many times the flooring repair is just the most visible part of a larger job that may involve rot repair or fixing other underlying damage to the subfloor and framing. On this job, we were called in to remove the return-air floor registers that fed the old, and now decommissioned, heating system. Before we could tackle the floorboard repair, we needed to install a framework in the hole and patch the subfloor.

Removing the first board is always the hardest

On this project, some of the floorboards ran continuously from one end of the room to the other, so you can imagine how it would have looked if I had tried to patch in this floor vent, which spanned across nine or ten pieces of flooring, with short pieces. Instead of always removing entire boards, though, you can make your own butt joints.

Tongue-and-groove flooring is fastened with nails driven through the tongue of each piece and down into the subfloor or framing below. The nails then are covered by the grooves of the next board that gets installed. To remove the boards, you have to gain access to the nails.

Avoid ripoffs

It’s tempting to rip off the bottom half of the groove on every replacement board before dropping the board into place, but that’s not as strong as having a full tongue-and-groove connection. To maximize the strength of the repair, I like to slide as many intact boards into place as possible. The fit has to be tight, so expect a lot of resistance. Once those boards are set and face-nailed sparingly, many of the remaining ones can be placed just as they would in a new installation. Drop in a new piece groove first, then toenail the tongue to the subfloor.

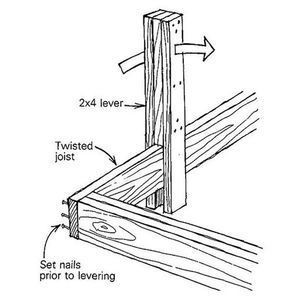

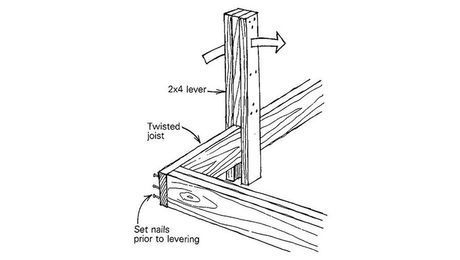

Wedge it

Plan for a full refinish

A great repair job still can be hard to blend in with the surrounding boards. Even if the repair planks match the existing floor—as they did on this job—the new boards usually sit proud of the existing floor due to wear, as well as sanding and refinishing that may have been done over the years. Customers don’t always like to hear it, but the best way to get a good match is to sand down and refinish the entire room, if not that whole level of the house.

If that’s not in the budget, then you have to get creative with color-matching the stain and blending subtle differences with colored wood putty. You can draw in the grain on any puttied sections that aren’t blending well enough. With the help of your thumb as a smudging tool, brown and black Sharpies can make almost any putty find the floor’s true color.

Photos by Justin Fink, Colin Russell, and Scott Sidler

Related stories:

- A Closer Look at Solid-Wood Flooring

- 2 Methods for Patching a Hardwood Floor

- Reclaimed Pine Boards Milled Onsite Into Flooring

From Fine Homebuilding #242

For more photos and details, click the View PDF button below: