How it Works: Circular Sawblades

Despite having no moving parts, circular sawblades are surprisingly complex.

Synopsis: Circular sawblades are surprisingly complex. In this “How It Works” article, Project House editor Justin Fink identifies their parts and explains how they contribute to the cleanness of a cut and the smoothness of a saw’s operation. He also discusses the different types of tooth grind as well as clearance angles and hook angles.

Despite having no moving parts, circular sawblades are surprisingly complex. The common carbide-tooth sawblade has to make three kinds of cuts at once: the cut into the material, the cut through the material, and the cut on the way out of the material. Through the engineering of the saw plate and teeth, the blade is able to perform each of these three cuts.

The wrong blade may still make the cut, but it won’t necessarily make it well or make it repeatedly without failing. Here’s how circular sawblades work.

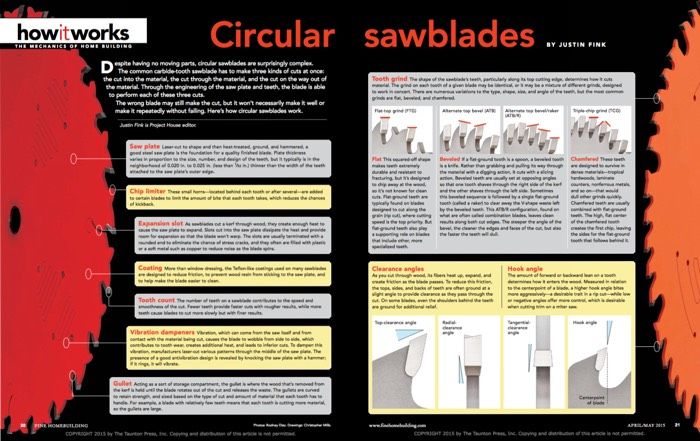

Tooth grind

The shape of the sawblade’s teeth, particularly along its top cutting edge, determines how it cuts material. The grind on each tooth of a given blade may be identical, or it may be a mixture of different grinds, designed to work in concert. There are numerous variations to the type, shape, size, and angle of the teeth, but the most common grinds are flat, beveled, and chamfered.

Flat- This squared-off shape makes teeth extremely durable and resistant to fracturing, but it’s designed to chip away at the wood, so it’s not known for clean cuts. Flat-ground teeth are typically found on blades designed to cut along the grain (rip cut), where cutting speed is the top priority. But flat-ground teeth also play a supporting role on blades that include other, more specialized teeth.

Beveled- If a flat-ground tooth is a spoon, a beveled tooth is a knife. Rather than grabbing and pulling its way through the material with a digging action, it cuts with a slicing action. Beveled teeth are usually set at opposing angles so that one tooth shaves through the right side of the kerf and the other shaves through the left side. Sometimes this beveled sequence is followed by a single flat-ground tooth (called a raker) to clear away the V-shape waste left by the beveled teeth. This ATB/R configuration, found on what are often called combination blades, leaves clean results along both cut edges. The steeper the angle of the bevel, the cleaner the edges and faces of the cut, but also the faster the teeth will dull.

Chamfered- These teeth are designed to survive in dense materials—tropical hardwoods, laminate counters, nonferrous metals, and so on—that would dull other grinds quickly. Chamfered teeth are usually combined with flat-ground teeth. The high, flat center of the chamfered tooth creates the first chip, leaving the sides for the flat-ground tooth that follows behind it.

For diagrams and a full breakdown of all the parts of a circular sawblade, click the View PDF button below.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

8067 All-Weather Flashing Tape

Handy Heat Gun

Affordable IR Camera