Engel’s Hierarchy of Needs ranks a shop right after food and family. I’ve had some sort of a shop since I was 14, but never a great one. I’ve had basement shops, garage shops, and illegally-converted-carport shops. Each was some dysfunctional combination of damp, cold, low-ceilinged, or poorly lit. That is changing. It’s taken about 6 years, and I have excellent excuses for that, but I’‘ve been building a shop that’s now to the point of being fitted out with tools and benches. From a practical perspective, it’s designed as a garage should a future owner prefer to house cars rather than power tools. Crazy talk, right? Some people do that, though.

Construction is moving apace now. Since December, I’ve hung the cedar garage doors I built two years ago; insulated, drywalled, trimmed, painted, and done the finish electrical work. The shop is bright, big, and has 10 ft. ceilings. It’s kept toasty warm by a woodstove my wife bought in 1983 in Utah, and which I’ve lugged from there to New Jersey to Pennsylvania, back to New Jersey, and finally to Connecticut.

I’m moving out of my existing cramped basement shop into the new one and relishing the challenge of setting things up as I want them while using up a bunch of stuff I already have. The whole shebang would probably be easier if I were inclined to draw projects in detail. I am not. My process is repetitively prioritizing and fitting, prioritizing and fitting. For example, my new-old tablesaw, a Delta Unisaw for which I traded a 1952 Farmall tractor last fall, will be the sun around which my shop revolves. For ripping long stock, it needs 16 ft. behind it and 16 ft. in front of it, counting doors and windows that align and can be opened as needed. It also needs 8 ft. to the left of the blade so I can trim plywood, and a location that’s easy to duct for dust collection. To meet these requirements, the tablesaw is centered in the shop.

After the tablesaw comes a mitersaw, set on a bench along a wall, which also can serve as a support table for crosscutting full sheets of plywood. As the tablesaw defines the center of the shop, the mitersaw defines one side. A 3 ft. x 8 ft. workbench, which will also serve as an infeed table for the tablesaw, completes my work triangle. A router table located behind the table saw will double as an outfeed table. The other big tools see intermittent use; so jointer, planer, and bandsaw are on wheels and can be summoned from valet parking in a corner when needed.

The mitersaw bench in my basement shop was perfectly good, and reusing it made sense. My son Kevin was home from UConn this weekend, and I dragooned him into helping me move the bench to the new shop on Saturday. However, there’s always something you have to do in order to do what it is you really want to do. My house has a walkout basement, accessed by a valley between two retaining walls. After Kevin shoveled the snow drifts away from the basement door, it was easy to lug the two 8 ft. long bench halves out of the basement. But there were still a couple of feet of snow on the 75 ft. of hilly ground between there and the shop. I plowed the snow off the lawn for access to the top of one retaining wall, where I used my tractor’s backhoe to pluck the bench halves from below. Which brings me back to Engel’s Hierarchy of Needs. A backhoe comes right after a shop. Maybe before. It’s a tough call.

I spent most of Sunday modifying and installing the bench. Because it consists of two halves, one on each side of the saw, I had to set them precisely so that both tops would be in plane with each other and the mitersaw table. For 40 years, I’ve had a 10 ft. long aluminum straightedge. Aligning those benchtops was the second time I used it.

It turns out that a piece of 3/4 in. plain-sawn oak veneer plywood that’s been in my way for a decade will produce 12 doors to enclose the bottom of this bench. I already have the hinges for those doors from storage cubbies in the attic playroom that I dismantled when Kevin and his brother outgrew Legos. And, kismet, it happens that my tool-actuated vac fits snugly under the bench beside the mitersaw. I drilled a hole in the bench top for the vac hose and a cord, and connected my mitersaw to dust extraction.

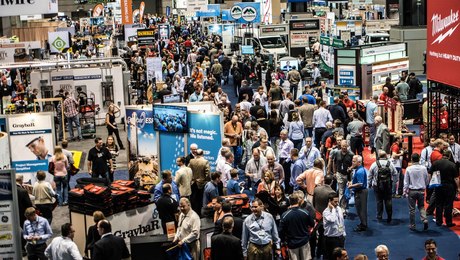

In years past, I earned some of my living doing tradeshow clinics on installing siding and finishing basements. I made two stout, rolling boxes from 3/4 in. plywood to transport my tools.They’re 24 in. deep, 20 in. wide, and 30 in. long. I’ve been tripping on them since I stopped doing trade shows 4 years ago. Cut in half along the 24 in. dimension, they’ll make excellent 20 in. wide x 30 in. tall x 12 in. deep wall cabinets. Once I’ve hung those cabinets, I’ll start putting away tools and sundries. When I’ve filled those spaces and can see what’s left, I’ll build more storage. Prioritize and fit, prioritize and fit.

That’s as far as I got Sunday night, stopping at 9 o’clock when I realized that I very much wanted dinner, two Advil, and an IPA. Did I mention that this was an awesome weekend?

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

8067 All-Weather Flashing Tape

Affordable IR Camera

Handy Heat Gun

View Comments

Wonderful work!

Great work done..

Well done..Keep it up..