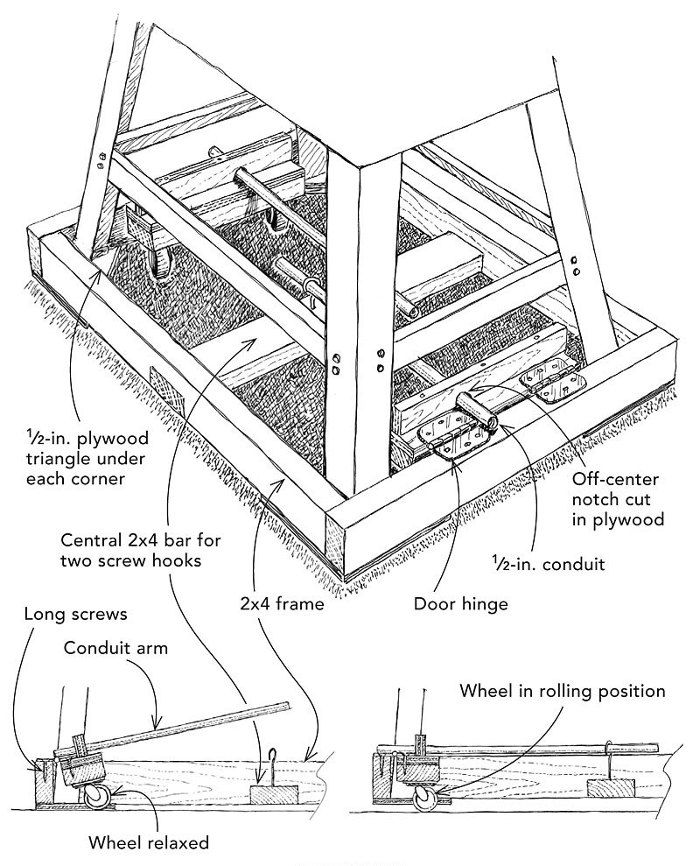

I built a rolling base for my bandsaw using scrap wood and hardware-store parts. The base is made from 2×4 studs sized to fit around the saw’s legs. Each leg is supported by a 1/2-in. plywood triangle fastened under each corner of the base. The wheel assemblies are made from 2×4 scraps and pieces of 3/4-in. plywood. I attached caster wheels to the bottom of the 2x4s and added the 3/4-in. plywood pieces to the top of the 2×4 sections as spacers, so the total height of the wheels plus the wood is about 3?4 in. higher than the frame when the wheels are down. The required thickness of the spacers depends on the wheels used. I used door hinges to connect each wheel assembly to the base. The vertically mounted length of 3/4-in. plywood on top of each wheel assembly is notched to hold a lever made from 1/2-in. metal conduit. The notch needs to be about 3/4 in. wide so that the lever can swing back and forth. Finally, I installed a center 2×4 rail with two screw-in hooks large enough to hold the conduit arms. To move the saw, I simply push down on each conduit arm and slip it under its hook. This forces the wheel assemblies down and raises the saw base for rolling.

Tom Schaeffer, Belleville, PA

Edited and Illustrated by Charles Miller

From Fine Homebuilding #254

View Comments

Great idea! Another alternative to shimming the top of the wheel ass'ys is to screw the hinge on the vertical inner side of the 2x4 frame... Less chance of binding or pulling on the hinge or screws. Also be sure to solidly glue and screw the bottom corner plywoods because they will be subjected to considerable combined forces of weight and vibration from the saw. I prefer to drill and insert 4 extra pieces of pipe horizontaly at 45 deg. through the corner 2x4s. Be aware the tablesaw surface height will be at least an inch higher with this method... M.L.