Carpenters working on job sites start every day by unrolling extension cords, and end every day by rolling them back up again. If they’re not careful, they end up with a bird’s nest that’s hard to untangle the next day. As it turns out, there’s a better way.

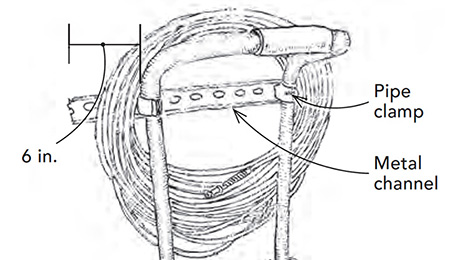

Ric Winters of Georgetown, Texas, has been using these homemade extension-cord and air-hose reels of his own design for over a decade. The setup uses plywood, PVC, and a lazy-susan bearing to make a heavy-duty reel that can hold a great deal of cord or hose.

View Comments

Important Safety Warning!!!

If you wrap up a cord on a reel you create a choke, and need to derate the cord by about fifty percent.

Another safety problem - the fittings and electrical box should be designed for outdoor use. Using a handi-box as part of an extension cord system is a pretty common OSHA violation. Also, if you're using an extension cord, it should already be plugged into a GFCI, making the one on the reel redundant.

You know...there is a reason we did things the way we did for the 45 years I was in the Trades. Please read the first two comments, this "better way" should be removed from the site before someone else thinks this is a good idea!

Jigs, how does wrapping a cord on a reel derate the cord by 50%?

Ted - I'm only an electrician part of the time, so I can't quote the exact code for you. The issue is heat build-up if a portion of the cord is still on the reel during use. We have all grabbed the end of a plug and found it warm/hot after heavy use, be it a power tool or vacuum cleaner. Now picture heat build up in the wire, while it is confined on the reel, next thing you know the whole reel is on fire. Derating it would limit the amperage demand, thereby reducing the chance for heat retention.