Build a Hybrid Timber-Frame Floor

Incorporate the beauty of structural timbers into a stick-frame house.

Synopsis: Custom builder Sam Koerber shares his approach for incorporating structural, decorative timbers into an otherwise standard stick-frame house using traditional timber-frame joinery cut with conventional tools. He discusses techniques as well as a sequence of assembly.

When I built my first house at the age of 19, I wanted it to be cheap but interesting. My dad suggested using doubled-up 2x10s for the floor joists, skinning them along the bottom edge with 1x4s to hide the seam, and capping them with tongue-and-groove planks. It amounted to a budget version of a real timber-frame floor, but it worked, and living in that house caused the look of exposed structural timbers to seep into my design psyche and become an essential part of my style. It was only after building a few more houses with this technique that I realized my doubled joists weren’t much cheaper than real timbers, and that although the look was OK, it still wasn’t what I really wanted. I had seen other builders apply solid, nonstructural timbers to finished drywall ceilings, but that seemed way too much work for what, to me, wasn’t authentic. So when the next opportunity came along, I went with a hybrid approach that I still use today: a conventional stick-built house that incorporates real structural timbers and traditional joinery, completed mostly with common carpentry tools. This represents an authentic and sparing taste of the timber-frame aesthetic.

Timbers can mix with 2xs

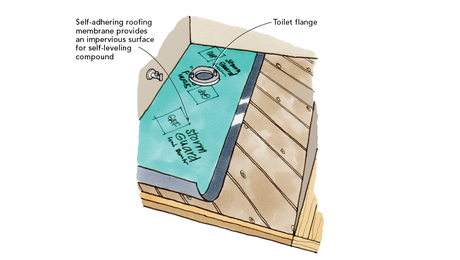

My usual approach is to frame one part of the main-level ceiling in timbers, and then use dimensional or engineered lumber elsewhere in the house. In order to make this work, the needs of each room must be coordinated with the realities of having exposed timbers, because you’re surrendering the drywall-covered joist bays that are used to hide mechanicals. Upstairs bathrooms need to be located so that waste lines are not visible from below. Similarly, if you want recessed lighting in the kitchen, it makes more sense to finish this area with conventional drywall.

You also need to think about beam and joist spans, and about whether you want to (or can) get away without posts. In most cases, posts are necessary, and they can reinforce the timber-frame look. The clients for the house shown here wanted a clear-span look, so we eliminated posts by supporting the beams with a trusslike setup connected to the roof framing above. Whether or not posts are used, beams and joists should be sized by an architect or engineer.

When the plans are finalized, they become your cutlist for ordering the timbers from a sawyer. I typically order posts and joists one or two feet longer than needed to allow enough room for the tenons to be cut, and I get a couple of extra joists in case I make a mistake during layout and assembly. For beams, I order only what I need, and I have them cut to exact length if possible.

For more photos and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Stabila Classic Level Set

Short Blade Chisel

Portable Wall Jack

View Comments

If this crew will be doing a lot of these Hybrid Timber-Frame houses, I would suggest that they invest in a Ligna-Tool Dovetail cutting guide [http://www.lignatool.at/en/schwalbenschwanz.html]. Using a router, this would produce a perfect dovetail joint w/o all the circular saw bevel cutting & chiseling. Ligna-Tool also makes self-aligning cutting jigs for end straight & bevel cuts on beams including compounds.