Floor-Framing Design

Designing the framing system for wooden I-joists and LVLs is a little different from dimensional lumber.

There are many materials you can use for framing a floor: standard dimensional lumber, heavy timber (as in timber framing or post-and-beam construction), open web joists, and wooden I-joists are the options I typically choose from, depending on the situation. For high-performance homes, a well-insulated concrete slab is usually the most cost-effective approach for the first floor, but the hillside site for the FHB House precluded that option. Wooden I-joists provide a good balance of strength, cost, and ease of installation, and they are what we are using for the floor joists on the FHB House, with LVLs for beams and headers.

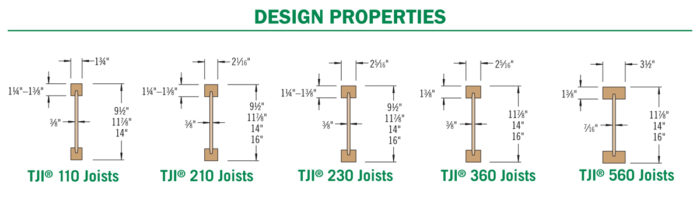

Designing the framing system for engineered lumber is a little different from dimensional lumber. While dimensional lumber, still the most common way to frame, is usually 1½ in. by 9¼ in. or 11¼ in. (or sometimes 7¼ in. or 5½ in.), engineered lumber comes in various widths, in depths of 9½ in., 11-7/8 in., 14 in. or 16 in. (or bigger; I’ve ordered them up to 24 in. deep), and in much longer lengths than dimensional lumber. (Some engineered lumber, such as LVLs, are also available in sizes that match dimensional lumber.)

Wooden I-joists are often called TGIs, a mispronunciation of TJI, the name Weyerhaeuser uses for their product line, after Trus Joist, the company that first developed wooden I-joists 50 years ago and that Weyerhaeuser now owns.

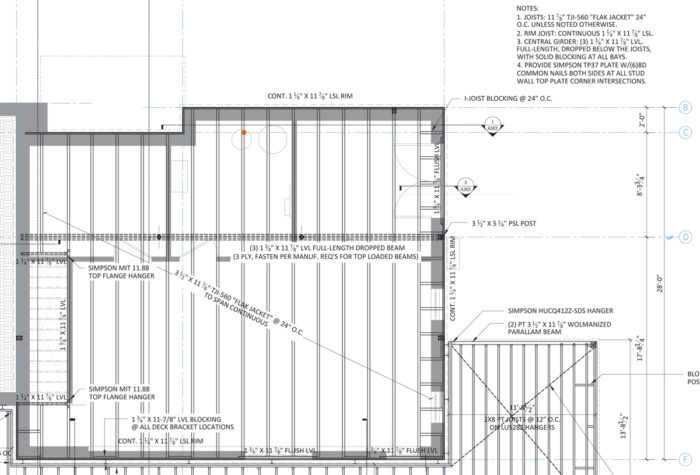

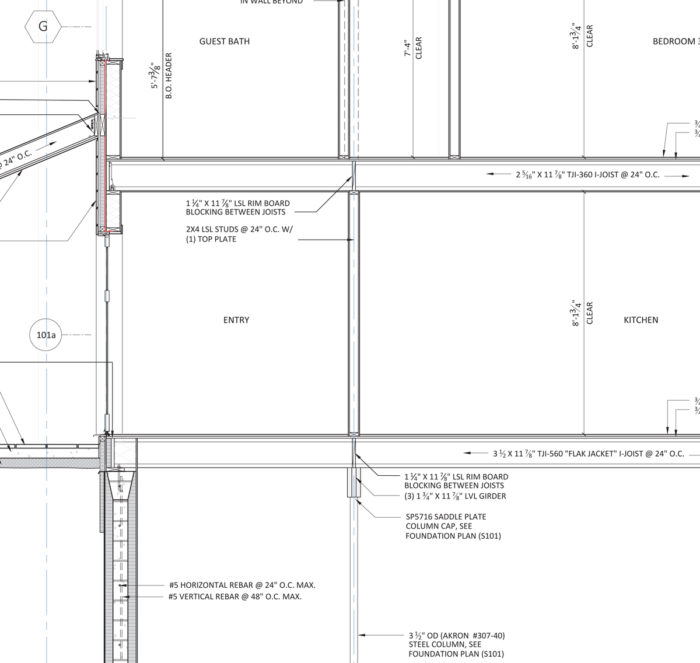

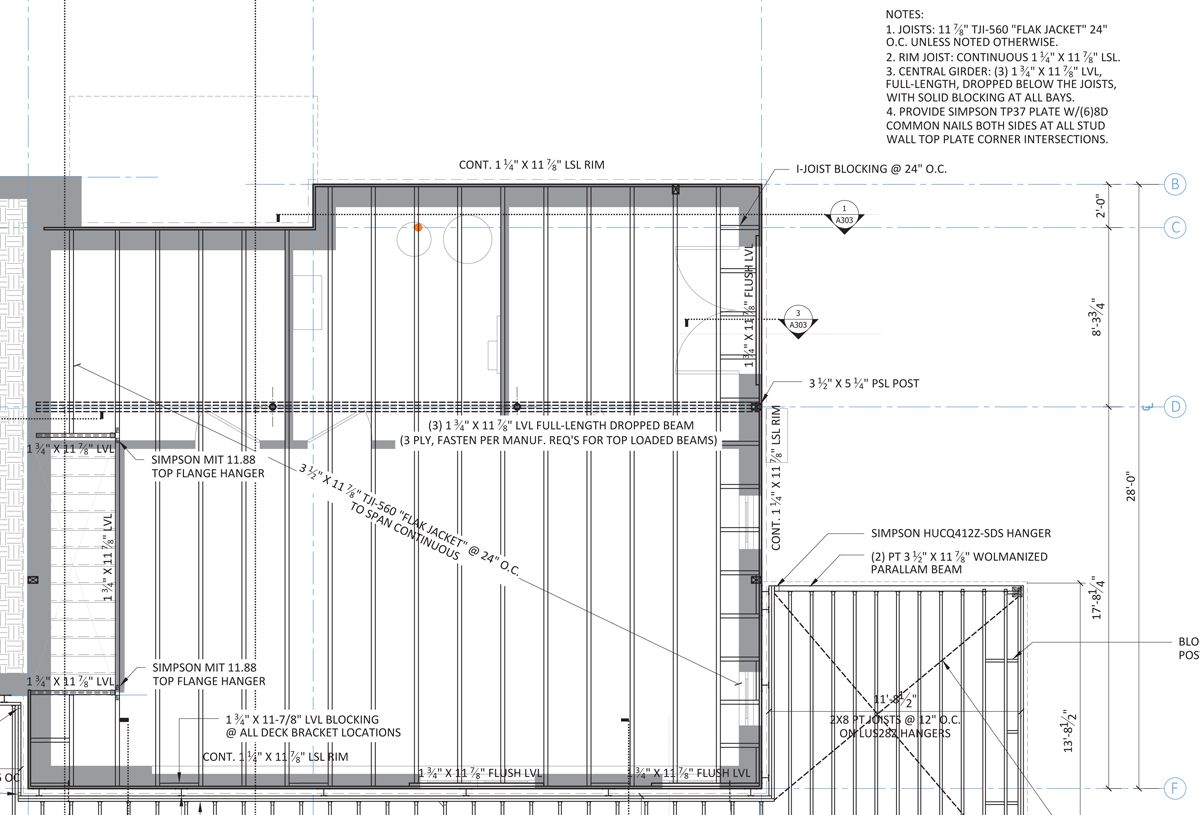

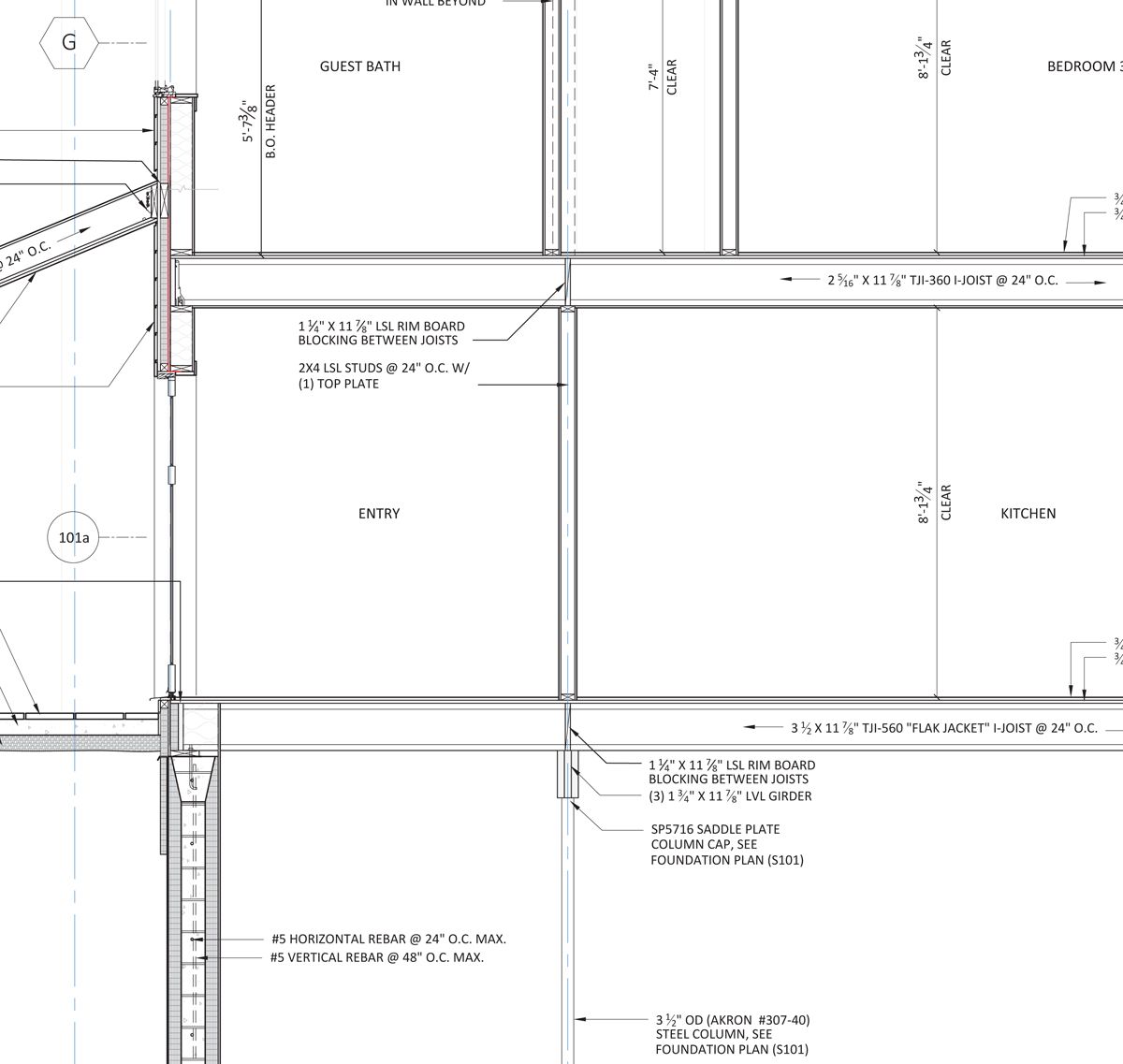

It simplifies construction when you can clear-span the floor joists, but while TJIs are available up to 24 ft. long (or longer, by special order), our roof framing system required support near the center of the house, so we used a typical center beam in the basement and a bearing wall on the first floor. We up-sized the center beam at the request of Mike Guertin so we could use fewer posts.

The beam and headers in the floor system are framed with LVLs, another type of engineered lumber. LVL stands for Laminated Veneer Lumber and is made like plywood, with thin sheets of veneer glued together, except that in LVLs all the wood grain is oriented in the same direction, resulting in much higher strength than if the beam was plywood, which has half of the grain oriented in the “wrong” direction. (Wrong in terms of beam strength; because they are not cross-laminated like plywood is, LVLs are not as dimensionally stable as plywood, a common misconception.)

LVLs and other engineered beams are rated primarily by their bending stiffness, technically called the modulus of elasticity (or M.O.E., or just E). I always spec an M.O.E. of 2,000,000 psi, which is sometimes abbreviated to something like E=2.0. The M.O.E. of solid lumber is usually in the range of 1,100,000 to 1,400,000, up to 1,600,000 for a really strong wood like clear southern pine. The spruce/pine/fir used for framing in the northeast (which is mostly red or white spruce) has an M.O.E. of 1,400,000 for the sizes and grades typically available. All that to say that an LVL is usually about 60% stronger than a dimensional beam of similar size.

There are other factors that engineers consider when sizing beams, the main ones being compression perpendicular to grain (aka crushing of wood fibers at bearing points), extreme fiber in bending (whether or not there is enough stress at the bottom of a member to actually pull the wood fibers apart), and shear (enough material in cross-section to prevent collapse of the member). Be careful when ordering LVLs; several times I have seen lumberyard deliver members with M.O.E.’s of 1,800,000 or 1,900,000 psi instead of the 2,000,000 psi that I spec’d. The difference is a beam that is not as strong or stiff as intended. While in most cases the difference wouldn’t lead to structural collapse, it will lead to excessive deflection, which in engineering terms is considered a failure, and in everyday terms means a floor that feels bouncy or that leads to drywall cracks and other aesthetic issues. Or a header that pinches down on a double sliding door (ask me how I know…).

The vast majority of the time, the factor that determines beam size is how much it will bend under load, and if you follow prescriptive codes or sizing charts for engineered lumber, that is how they are arranged. Floor members (joists, beams and headers) are sized to limit bending (technically called deflection), under dead loads of 10 to 20 pounds per square foot of floor area and live loads of 30 lb./ft.² (for bedrooms) or 40 lb./ft.² (for living areas). Code minimum for floor deflection is L/360, which means that with the loads above entered into a formula that also takes into account the shape, size, length and M.O.E. of the beam, it can deflect no more than 1/360th of the length of the beam. That’s about ½ in. for a 14-ft. joist span. For longer spans, L/360 can allow a floor that feels bouncy, so I usually go with the stiffer option of limiting deflection to L/480. For a 14-ft. joist, that’s about 3/8 in. No matter the length of the joist or beam, I limit deflection to no more than 5/8 in. Code books and manufacturer specs often make it easy for anyone who understands what they’re looking at to size their own members, but they can’t cover every situation and I don’t like to waste material so I tend to size my own members or consult with a licensed engineer.

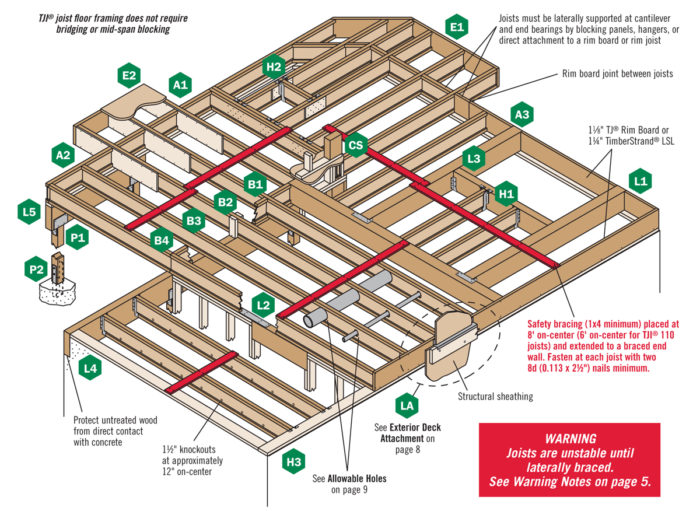

Back to the TJIs. There are some unique things to consider when working with them, the biggest one being point loads. They are very strong in bending, considering the amount of material in their cross-section, but their narrow webs cannot handle much of a point load, so pretty much anywhere there is a load more than the basic floor load—anywhere there is a weight-bearing post or wall above or below the joist—additional material is needed, either web stiffeners (plywood or OSB attached to the face of the web), solid blocking (various materials, depending on the situation) or squash blocks (blocking oriented vertically as a mini-post).

When joist hangers are needed, they often look different from standard face-mount hangers. They can be top-mounted, to be hung off the supporting member, or they can have an indexing tab that sits on the supporting member to set the hanger at the right height, with face-mounted nails.

Design information for TJI 110-560 joists

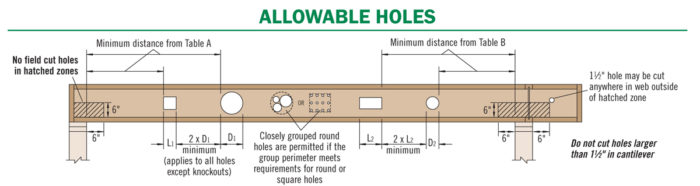

A big advantage of using TJIs, as compared to dimensional lumber, is the flexibility in drilling holes for running wires and especially larger holes, such as those needed for plumbing drains or HVAC ducting. The specifier’s guide shows that you can drill or cut holes almost anywhere within the web, with some limitations to size and adjacency, especially where shear stresses are relatively high (such as near each end and where it runs over a beam or bearing wall).

It is often possible to use TJIs as headers or beams, but when it requires doubling the member and filling in the web with stiffeners, I often find that it’s simpler to just run an LVL instead.

In a wooden I-joist, as in any other joist or beam, the top and bottom of the member do most of the work, with the top flange usually in compression, the bottom flange usually in tension, and the web mainly there to hold the flanges apart. To make the beam stronger, you can either push the flanges farther apart (by using a deeper member), which has the same effect as using a longer pry bar to pull a nail, increasing the leverage or torque within the beam. Another way to make the beam stronger is to keep it the same depth but to use more material at the flanges. As the load capacity increases, eventually the web must also get thicker or stronger to keep it from buckling under the effort of holding the two flanges apart.

For the FHB House, we wanted to keep all of our framing at 24 in. on center, which can be the topic of another post. Compared to 16-in.-o.c. spacing, that means 50% more weight per linear foot on each joist, so our engineer determined that we needed to use the heaviest grade available in the 11 7/8-in. thickness we wanted to use. That is the beefy TJI560, with flange dimensions of 1 3/8-in. by 3 ½ in. and a web thickness of 7/16 in., slightly more than the 3/8-in. webs they use for their other grades.

For areas where there could conceivably be a fire risk, we are trying a new offering from Weyerhaeuser, their “Flak Jacket” coating for the TJI’s. In their words: “TJI® joists with Flak Jacket® protection meet 2012 IRC requirements for fire protection of floors and give you an effective one-hour-rated assembly for multi-family projects.”

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Bluetooth Earmuffs

Smart String Line

Stabila Classic Level Set

View Comments

What about the recall of fire rated joists? Not one word in the Fine Homebuilding website.