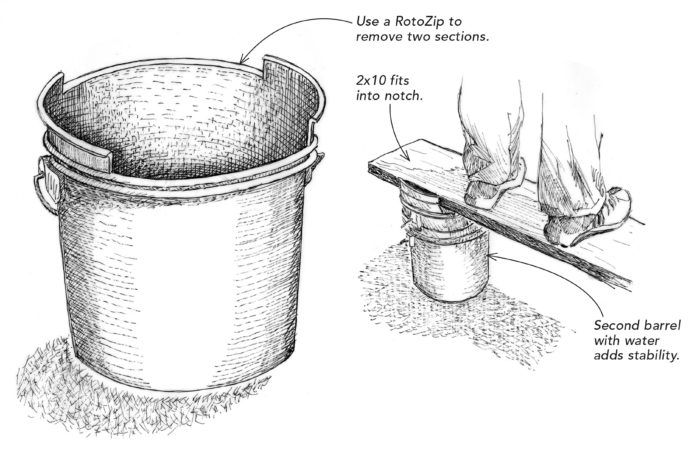

I found a way to tweak the traditional mud-bucket platform to work even better. I used my RotoZip to cut two pieces out of the top of each bucket, about 11⁄4 in. deep and wide enough to fit a 6-ft. 2×10 that spans the distance between two of the buckets.

On sites with higher ceilings, stacked buckets make the rig a little taller. In this case, I fill the bottom buckets with some water to increase their stability.

—Michael Ratway, Stafford, Va.

Edited and illustrated by Charles Miller

From Fine Homebuilding #262

View Comments

If you turn the bucket benches over and attach them to a 2x10 or 2x12 with a bolt, they are more stable and can be easily moved around as your work progresses.

I prefer to attach folding metal legs. You have to carry the plank anyway. Saves you dragging two or four buckets along and/or looking for water to weigh down for more stability

Do you post a lookout for OSHA inspectors?

Might work fine with relatively new buckets, but the plastic they are made from gets brittle as they age and may prove to be a problem. And, as CivilEng43 mentions, OSHA might not approve should they happen to visit.

Wow? I read this and my first thought was, "Who at Fine Homebuilding found this "TIP" worthy of putting out". The safety aspect alone should have been enough to to politely say Not NO but HELL NO. Both CT_Yankee and CivilEng43 are correct.

For the amount of money and time spent you could have bought a Gorilla platform or Werner platform during the Christmas sales at one of the box stores.

And lastly, NOT ON ONE OF MY JOBS.

This was a Tip that should have never made it to this platform.