Designing High-Performance HVAC

The ProHOME uses three minisplit systems, each 9000 Btu/hr.

During the planning phase of the house, Mike Guertin indicated he wanted an all-electric house rather than relying on fossil fuels for heating, like most houses in the region. The most straightforward, economical approach for electric heating and cooling is an air-source minisplit system. Sonia Barrantes, the mechanical engineering consultant for the ProHOME, used a combination of BEopt and Trane’s TRACE 700 software to calculate the heating and cooling loads for the house and for each room to ensure that there wouldn’t be a particular room that was never quite comfortable.

The single outdoor Mitsubishi compressor unit is sized at 2 tons and will be installed on the east wall of house, high enough off the ground to keep it above drifting snow. The three indoor units are each 9000 Btu/hr. Although it wasn’t intentionally planned as such, the system designed for the ProHOME uses each of the three distribution systems available for minisplit systems. The basement will have a traditional wall-mounted head unit — the type most often associated with minisplit heat-pump systems — mounted on the east wall. While this location keeps the line sets to the compressor short, it is important that the air handler be well away from the stairs. Sonia warned that putting the unit too close to the stairs could cause the stack effect to pull the warm air upstairs, short-circuiting the intended path of hot air.

The first floor has a ceiling-mounted cassette in the dining area that distributes air in four directions. The ceiling cassette overcomes the objections that some people raise about ductless split systems — namely, that the air handler takes up real estate on the wall and isn’t especially attractive. The unobtrusive, low-profile ceiling cassette is less than 2 ft. by 2 ft. It fits between the TJIs in the ceiling without any framing modifications and looks like the grille of a large bathroom fan. This method of distribution is great for the open floor plan on the first floor and will push air throughout the level. Because the flex room in the northeast corner can be closed off, Sonia recommended a small electric wall heater, but it’s unlikely to be used much. The separately ducted ventilation system will help distribute conditioned air throughout the house and reduce temperature differentials between rooms.

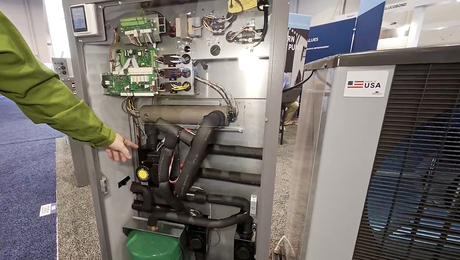

The second floor has a ceiling-concealed ducted indoor unit distributing conditioned air to each of the rooms. This style of air handler was chosen to ensure even distribution of air. Many well-insulated houses with minisplit systems rely on a single head unit placed in the hallway, and the homeowners are comfortable with the temperature differentials that occur when bedroom doors are closed. In the winter, the slightly cooler sleeping temperature in a closed bedroom is preferred by many people; in the summer, the opposite occurs, and bedrooms a few degrees warmer than the set point could feel uncomfortable. The indoor unit and supply ducts to each room are located in a hallway ceiling chase to keep them beneath the air barrier and inside conditioned space. Wall-mounted Tamarack return-air pathways allow airflow back to the single return register in the hallway.

View Comments

A very nice article and useful article. Designing high performance HVAC into a commercial and industrial building is a tough job. As industrial and offices uses HVAC to keep all the employees warm and cozy in the winters and cool during the scorching heat. HVAC systems are also used to keep products in good condition and to efficiently use boilers and cooling towers. Therefore a professional help from HVAC repair New Jersey - http://www.airdexinc.com/commercial-hvac-services-nyc/facility-planning/ is needed for proper design and planning for HVAC system

Incorporating supervised machine learning into HVAC systems’ working algorithms is the latest demand of building management systems. You have shared insights from designer’s point of view, but an equal importance is to integrate data processing algorithms into central unit of an HVAC, so that it can process more data to become budget friendly while ensuring the superior outcomes. As much quickly, the data can be processed, as better will be the HVAC system.

This is a technical point. What do you think?

This is an article on the same topic.

https://clevair.io/blog/machine-learning-is-building-managements-biggest-asset/