Strong Floating Shelves

To make a floating shelf, the best way is to start from the framing.

Begin with layout. Where your shelves will be, length, thickness and make sure that what you will be putting in the wall will support the weight of the shelves. Also take into consideration what will be sitting on the shelves.

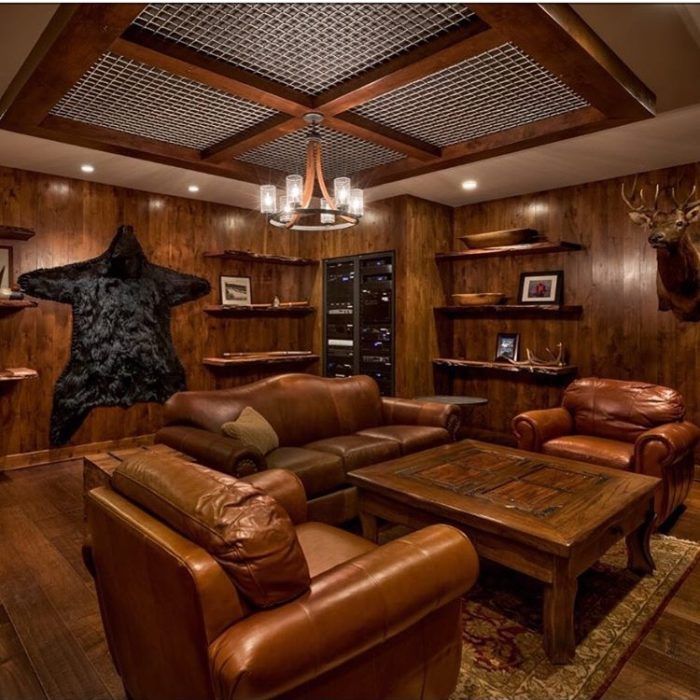

The shelves installed here were redwood brought in from California for a man cave and were a predetermined length and width. We wanted it to be as stout as possible so we decided to have steel brackets made by our friends at Beyond the Grain. This design was an ongoing process so, we then cut open the walls at the locations needed to lay out and install the brackets. We used a laser to assure all of the brackets were installed at the exact same height across the room. After everything was set up and fastened properly we reinstalled the insulation and drywall.

After closing up the walls we clad them with 6″ alder to start finishing out the room. We also tried to keep the wood as close to the steel as possible to strengthen the brackets further. Each slab of redwood was custom fit to each location. First, by cutting the live edge off of the side less favored and cutting to a size near 48″. We wanted them to be more natural so we didn’t hold it to exactly 48″ if it looked better. After cutting to fit we drilled 3/4″ holes, in the back of each slab, at the location of each bracket to accept the steel and fit the against the wall. To finish them off we scribed each shelf to fit against the walls.

Each shelf was left loose so the finishers could remove them and get the, walls painted, and shelves and ceiling details stained and clear coated. When complete, we double checked all the shelves for fit or movement, cut if needed and applied construction adhesive to all of the brackets and shelves to permanently lock them into place.

The shelves added a lot of character to the room and not having any brackets below them gives it a much cleaner look.

Follow us on Instagram @jpmconstructioninc for more process and project pictures and videos

Credits –

- Homebuilder and Designer – Brad Brown – Archistructure Homes – Instagram Profile @archistructure

- Steel brackets and alder made and milled by Brian Michaelis – Beyond the Grain – Instagram Profile @beyondthegraininc

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Original Speed Square

Smart String Line

100-ft. Tape Measure

View Comments

The room looks nice, but the shelf brackets look kind of wimpy. Real men have shelving that will carry 50-100 lb/sf.

yes, a close up of the brackets would've been nice

Beautiful! Love the natural edge on the shelves. Federal Brace has some shelf supports that will hold 50 pounds each, if you don't have time to wait for custom or a connection with a fabricator. We love FineHomebuilding projects. Keep them coming.

I built a wood paneled office for a client. Every surface had wood paneling on it. I really like the rustic edge on the shelfs.

Would also like to see close-up photos of the brackets. They look like they're mounted directly into the wall/studs or using drywall anchors.

For a heavy duty shelf, I like to use a stud mounted bracket that mounts to the side of the stud. However, the downside is the wall needs to be removed. But....the shelves can hold a couple hundred pounds (A real mans shelf)

I used to make them myself using rebar and spare metal I had laying around, but now I buy them from right on bracket. I'd recommend checking them out for heavy duty brackets.

https://rightonbracket.com/product/fireplace-mantel-bracket/