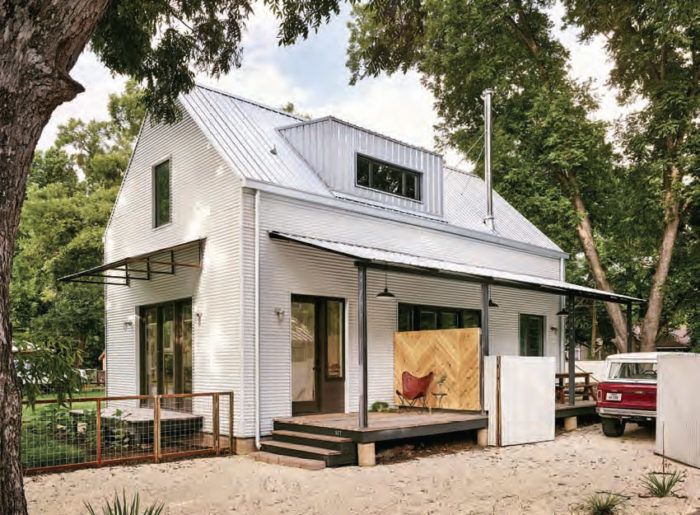

Best New Home 2017: For the Sake of Simplicity

A skillful execution of building-science principles and the quest for a simple, long-lasting home allow a unique detail to shine: the framing.

Our 2017 Best New Home Award goes to Matt Risinger and Eric Rauser of Risinger & Co. A skillful execution of building-science principles and the quest for a simple, long-lasting home allow a unique detail to shine: the framing.

When Greg Heidel told us that he wanted to “simplify the systems” of his life, he was speaking our language. Greg is a single guy who had recently purchased an empty lot in East Austin, Texas, an up-and-coming neighborhood. He wanted to build a new house that supported his lifestyle. Greg spends his time volunteering and saving money to donate to causes that are important to him, so he didn’t want a house that would be expensive to heat and cool or one that would require a lot of time and money to maintain. We don’t design many homes—we’re building-science geeks, and we typically add our knowledge to other architects’ designs. But Greg offered us the opportunity to both design and build his house, weaving proven building science into the plan from the get-go. We had the perfect approach in mind.

Outsulation is universally smart

Since we first read Joe Lstiburek’s 2007 article, “The Perfect Wall,” which describes an utterly simple yet radically unconventional building envelope, we’ve wanted to put it into practice in one of our projects. In the article, Joe outlines a wall assembly in which four control layers—one each for rain, air, vapor, and temperature—are installed outside the framing. Using this approach, the control layers protect the structure from water, vapor, and temperature swings, creating a more durable building. Though it is certainly still an option to put more insulation on the inside of a perfect wall, one of the main differences between this approach and the way most walls are built is that the primary thermal layer is on the outside. This assembly works in any climate; typically the only necessary adjustment is the thickness of the insulation. Another significant difference is that the purpose of the siding (and perhaps the way we should think of all siding) is only to protect the control layers from UV radiation.

The perfect wall is also the perfect roof and the perfect floor. Only slight tweaks are made when changing planes. Integrating the control layers as they transition from the slab to the walls and the walls to the roof is important. The layers must be continuous.

Nicknamed “the 500-year wall” because it is possibly the most durable way to build a house, the perfect wall approach met Greg’s desire for low maintenance. And once we’d decided that the insulation would be installed outside of the structure, we were able to explore a unique design possibility that this approach offers.

There is no drywall to be found in this house. Everywhere you look, you see structure. Yet designing the home wasn’t as simple as just leaving the structure exposed. There was a lot to consider and research before we even presented this idea to Greg.

For more photos and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Anchor Bolt Marker

100-ft. Tape Measure

A House Needs to Breathe...Or Does It?: An Introduction to Building Science

View Comments

Awesome ! The exposed framing is sweet guys, nice work.

How can members get more details - example how is home wired for plugs and ceiling lights with open walls ? Is there plans for sale when FHB publishes there winning homes?

Is the foundation completely made of cement or just the perimeter and cement under piers and then filler?

Hats off to the builders, especially for building without sheetrock, that great enemy of ambience. Using shiplap as the sheathing exposed to the interior instead of plywood or OSB was obviously pretty important to them. Framing exposed or not, shiplap, painted or left raw, deserves to be used a lot more for interior walls.

The interior design of a house needs to take into consideration what it would be like for the occupant, e.g. for reason of sickness or injury, to lay around for weeks or months looking at 4 sheetrock walls and a sheetrock ceiling.

I’d like to see more details on how they managed to hide the electrical and plumbing.

"It turns out that even the building inspector liked the idea that the wall cavities would be exposed. Because the cavities are not continuous between floors, the inspector saw the open walls as advantageous for fighting a fire, should one occur."

With all that wood to feed the flames, I would think the structural integrity of the first floor would be seriously compromised rapidly before the firefighters arrived and applied water. Whether or not the flames reach the second floor, how long will those "sweet" exposed burning first floor studs and joists be able to hold it up?

I would think a building department (and the insurance company) would want to see some realistic data on this type of construction.

Building Science should be based on experimental data, not opinion. Take two full scale two-story houses, one built using these new building techniques, and the other with full drywall. Set a fire on the first floor of each to see what happens during the realistic time before water is applied to them. Has this been done? If not, where's the science?