Faster Drywall Finishing

Automatic tools produce better walls in less time.

Synopsis: In this article, Brian Kitchin and Nick Aitchison, the owners of Drywall Nation, give an in-depth look at all of the available tools for drywall finishing. The article includes the uses and price of each tool: a nail spotter, a flat box, a loading pump, an angle box, an angle head, a corner roller, an automatic taper, a dust-collecting vacuum, a drywall sander, and drywall stilts. The article gives a description of how each tool is used for drywalling, a photograph of the tool in use, and tips for using the tools and materials, including how much water to add to the joint compound, how to use the automatic taper’s creaser wheel, and when to use extension handles for angle heads, flushers, rollers, and spotters.

Drywall Tools (from left to right):

- 3-in. Nail Spotter: Coats screw heads with compound, $300

- 14-in. Flat Box: For ceilings with raking light, $340

- 12-in. Flat Box: Applies second and third coats to seams, $330

- 8-in. Angle Box: Works with angle heads ($350 ea.) to coat corners, $389

- Loading Pump: Fills taping tools with compound, $390

- Angle Head: Smoothes corners after taping and rolling, $350

- Corner Roller: Fully embeds tape in corners, $200

- Automatic Taper: Applies compound and tape to seams and corners, $1300

- Festool CT 36: Tool-triggered dust-collecting vacuum, $756

- Festool Planex: Dust-collecting drywall sander, $1150

- 15-in. to 23-in. Drywall Stilts: Brings high work within reach, $280

Whenever we see professional drywall finishers hand-taping a new home or addition, we wonder how the builder who hired them can afford to lose so much time on the job. With modern taping tools —most of ours are made by Columbia (columbiatools.com)—the two of us can tape and finish an entire 2,400-sq.-ft. house in about four-and-a-half days. The same work with hand-taping tools would easily take two or three times as long.

So why do some drywallers stubbornly refuse to use automatic tools? Our guess is they’re intimidated by the learning curve—it takes a few jobs to become truly proficient—or they’re scared off by the price of a setup.

If you’re not willing to spend $3,200 or more to buy the tools all at once, you can significantly boost your efficiency with a pair of flat boxes and a loading pump to fill them, which adds up to about $1,300. In a second round of purchases, get an automatic taper ($1,300) and an angle box with 3-in. and 3-1/2-in. angle heads ($750) for finishing corners. Another option is to rent equipment from drywall tool manufacturers.

Load the tape and mix the mud

Automatic taping tools all require thinned mud to work properly, so we use a sopping-wet grout sponge to add water to lightweight all-purpose joint compound. Then we mix the thinned mud for a few minutes with a heavy-duty drill and a mud paddle. Mud for the automatic taper gets 5 to 6 sponge squeezes, mud for angle boxes gets 4 to 5 squeezes, and mud for flat boxes gets 2 to 3 squeezes.

Quicker corners. When taping inside corners, flip a lever on the tool’s housing to deploy the creaser wheel, which folds the tape and pushes it into the corner.

Faster taping. Loaded with joint tape and thinned compound, an automatic taper can tape seams and corners quickly. As the tool advances, it rolls out the tape and dispenses the compound at the same time. Another finisher on the three-person crew follows behind with a taping knife to fully embed the tape and smooth the joint.

Finish coats feather out faster

Like with hand-taping, joints and corners get progressively wider with the second and third coats of compound. Most drywall contractors who rely on automatic tools have flat boxes and angle heads in two or three widths.

Adjust the flow. The eccentric cam adjusts the flow, so you can determine the amount of compound to dispense. The idea is to fully coat the seam without excess and leave a smooth finish free of voids as you go.

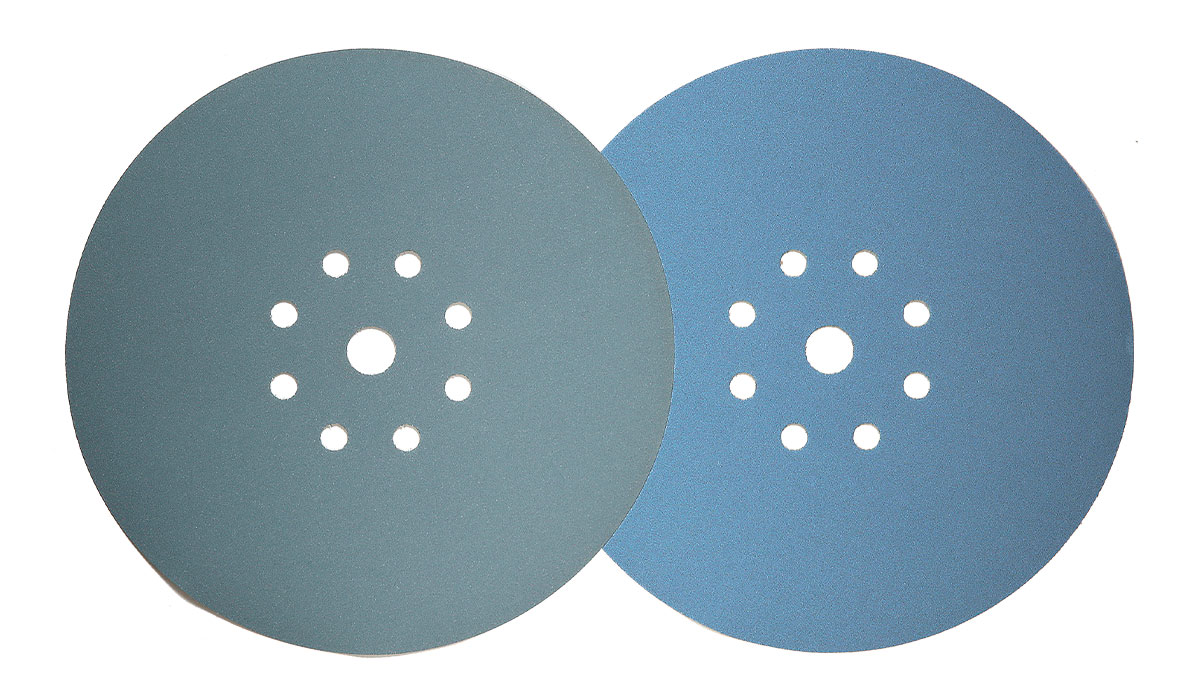

Blue grit

Before applying the final coat of compound, sand the joints and corners with 150-grit sandpaper. The final coat of compound is sanded with 220-grit paper. Festool’s 8-1/2-in. discs are color-coded for easy identification.

Click the View PDF button below to view the article as a PDF: