Magnesium Oxide Does It All

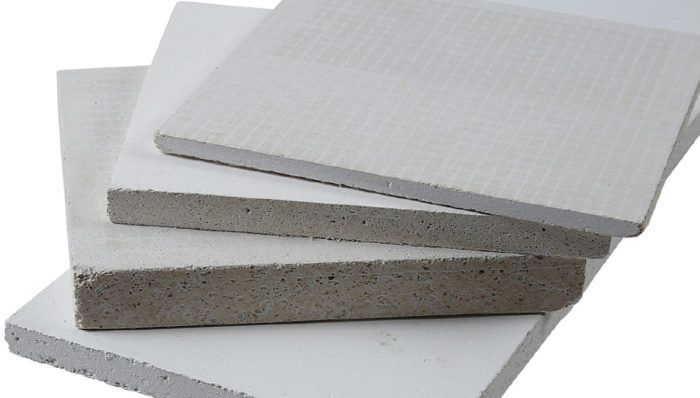

Impressive strength, as well as its fire, mold, and insect resistance, make MgO board suitable for a wide range of applications.

If you’re not familiar with magnesium oxide (MgO) board, you’re in good company, as it’s only starting to make its way to this country from widespread use in Asia. Extremegreen’s MgO board’s impressive strength, as well as its fire, mold, and insect resistance, make it suitable for a wide range of applications, from tile backer and wall panels to exterior trim and lap siding.

Bob Nilsen, a builder from Millbrook, N.Y., had to tackle the learning curve when MgO board was specified for 1/2-in. by 6-in. lap siding on a recent project. He told me that cuts are smooth and easy with conventional carbide-tipped circular saw blades and that ordinary bimetal jigsaw and multitool blades work fine for cutting around penetrations. His crew fastened the siding with pneumatic roof nailers, but, according to the maker, it can also be fastened with high-quality screws (conventional black drywall screws sometimes snap off), framing nails, and siding nails. Nilsen told me he liked working with the material better than fiber cement, because the dust wasn’t as irritating and the composition is easier on cutting tools. He also told me that throwing the material in a bucket of water for two months had no effect.

Builders who work in multifamily and commercial projects might see MgO board sooner than residential builders, because the material’s extreme fire resistance can eliminate the need for a second layer of drywall (and its associated material and labor costs) in many fire-rated assemblies.

Extremegreen MgO board is available through BlueLinx at local lumberyards. As of June 2017, distribution covers most of the United States, and nationwide availability is expected soon. In small quantities, 1/2-in. MgO board sells for $1.10 per sq. ft., 5/8-in. for $1.40 per sq. ft., and 3/4-in. for $1.60 per sq. ft.

View Comments

Does Extremegreen manufacture this product in the USA? Is there any North American manufacturers?

Note: do not use metal nails, screws, etc unless there coated with an Epoxy like coated steel screws which have an epoxy based polymer resin overcoat. The epoxy coating provides excellent corrosion resistance and is designed to adhere to the screw, even after it's inserted into MGO annd or other synthetic products. Anything other then a coated screw may break or crack the MGO boards?