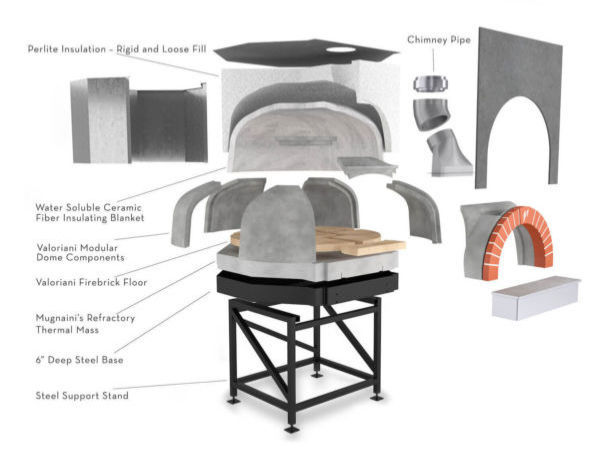

In their workshop in California’s Sonoma Valley, the artisans at Mugnaini marry their own custom-made steel frames with precast components from renowned Italian oven maker Valoriani before wrapping the assembly in stucco, sheet metal, or a custom material of your choice. The combination of time-tested European materials and modern American technology produces ovens that are easy to install and use. If a full-size wood-fired oven doesn’t fit your home or your lifestyle, the new Piccolo 60 portable gas oven may be the perfect way to get your start in pizza making. Mugnaini’s masonry kits are at the other end of the spectrum as starting points for completely custom ovens. With the numerous sizes, shapes, and finish materials available, it’s best to contact the folks at Mugniani and perhaps even take one of their introductory classes to figure out which oven suits you best.

- Preassembled ovens ship ready to install in your house or outdoor kitchen

- Steel oven stands put ovens at a comfortable height for cooking

- Portable gas oven: $3,750; preassembled ovens with steel bases start at $5,750; Masonry oven kits: $2,550 – $4,950

Preassembled Mugnaini ovens stand alone and are ready to use once you’ve found a spot for them in your home. Or, like the masonry kits, they can be built into your outdoor or indoor kitchen.

Each preassembled oven consists of a number of proprietary hand-built and precast components, and can be left for you to clad or wrapped in a variety of custom materials.

View Comments

Can coal be used in these ?

No, it will make your pizza taste nasty, since the fuel and the food are in the same space.

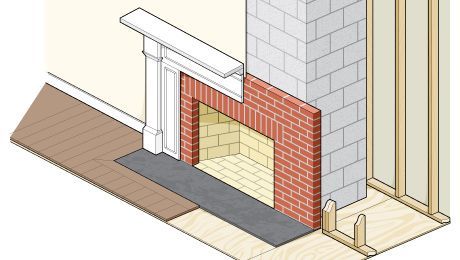

I've built a couple of traditional bread/pizza ovens- they don't have chimneys, but depend on air intake at the bottom of the arched opening and exhaust at the top.

One was somewhat like the picture, a fire brick base over concrete and a half-cylinder firebrick chamber, with a slightly smaller firebrick arched opening, sand over that for thermal mass, then perlite around everything for heat retention. I buried a couple of diesel exhaust pyrometers in the masonry to get some sense of relative internal temps.

The other was a traditional dome oven, made of cob, a mixture of clay, sand, plus straw in the outer layer, again, on a brick base. We made a hemispherical form of wet sand held in place w/ wet newspaper and a wooden arch as a form for the opening.