Protecting Foundation Insulation

A heavy gauge of metal flashing offers increased durability if you plan to let it contact the ground.

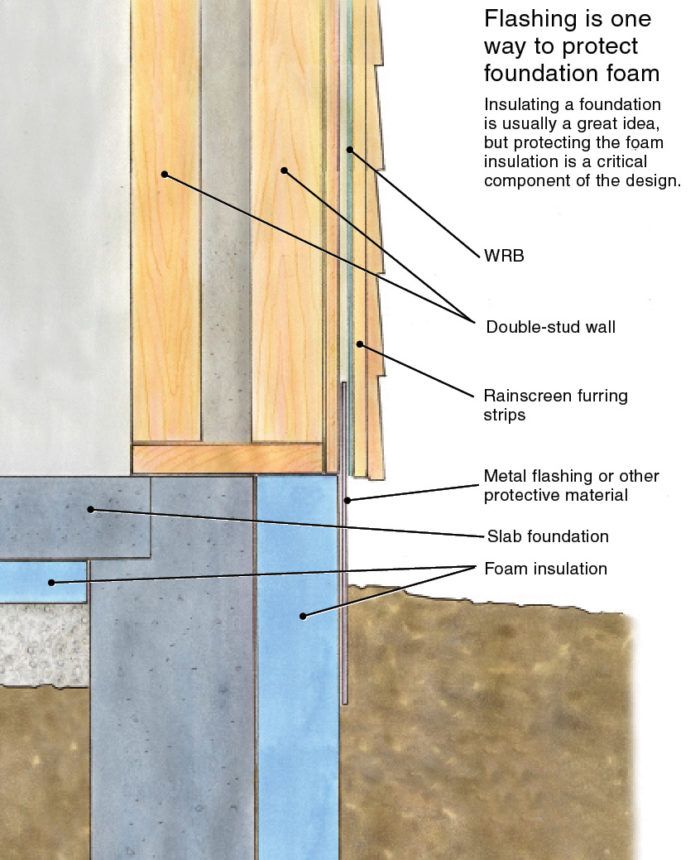

We are in Minnesota (Zone 6a) and building a 2200-sq.-ft. slab-on-grade home. It will have a 10-in.-thick double-stud wall that cantilevers 4 in. beyond the foundation to sit flush with the outside face of the 4-in. foam applied to the edge of the slab. I plan to protect the foundation insulation using painted aluminum flashing nailed to the sheathing and extending down below the backfill. All the wall finishes will lap the flashing. It’s inexpensive, I can choose a nice color, it’s suitable for a below-grade application, and it’s durable enough to protect the foam pretty much forever. Actually, it seems too easy, which makes me immediately wonder—what am I missing?

—Scott K., via greenbuildingadvisor.com

Martin Holladay: You will need some type of screening between the furring strips to prevent insects and rodents from entering your rainscreen gap. But except for that, your planned approach doesn’t raise any

red flags.

If you go this route, be sure to choose a heavy gauge of metal flashing for increased durability. The possible disadvantages are that the metal flashing can get dinged up over the years, leaving the bottom of your house looking like a metal entry door that someone has tried to kick in. The thicker the flashing, the less likely it will look dinged up.

There is no perfect answer to the question of how to protect above-grade exterior foam. While metal flashing is a good solution, it’s not the only possibility. Here’s a list of materials that can be used to protect the above-grade portion of the exterior rigid foam used to insulate a foundation wall:

• A brush-applied cementitious coating or cementitious stucco (for example, Styro Industries Brush On ST), with or without metal lath

• A trowel-applied cementitious coating that includes chopped fiberglass (for example, Quikrete Foam Coating or other surface-bonding cement)

• An acrylic coating like Styro Industries FlexCoat or Styro Industries Tuff II

• An exterior insulation and finish system, or EIFS (synthetic stucco)

• Cement backerboard, with or without a layer of stucco

• Pressure-treated plywood

• A fiberglass panel like GroundBreaker from Nudo Products

• Styro Industries FP Ultra Lite panels (XPS with a coating of mineral granules adhered to one side)

• Protecto Wrap Protecto Bond (a flexible peel-and-stick membrane with a textured, gritty coating)

• ProGuard Concrete Insulated Sheathing

View Comments

I have the same situation here on a home I'm building for myself. The foam was given a coat of Quickrete coating. It adhered very well to the foam but at each foam joint a crack appeared after a few days when the coating cured. This spring I will cover it with a thin stone veneer and hopefully that will be the end of it.

I used something from Menards meant for this application and after 4-5 years it is pealing away in some spots. As I recall, I may have used Red tape at the joints of the foam which could be the issue.

Why not get the best of new ideas and run that insulation up the side wall. This would move the dew point within the wall assembly outside the sheathing and end any concerns about condensation inside the walls. The double stud wall could be reduced to a single 2x6 wall. which would simplify construction. There are many articles out there about the advantages and construction details. Yes I know this wasn't the original question.

No red flags? Where is your termite shield? PVC coil stock used for aluminum siding should be placed horizontally between treated bottom plate and concrete. Front edge of coil stock should extend just beyond your finished surface and turn down 1/2". I will forward pictures on request. Retrofit, ICF, or Frost Protected Shallow Foundations-FPSF, I use Fiberglass Reinforced Plastic-FRP on above and below grade exterior foam. FRP is cheap, durable, widely available, and adheres great to foam. I also use FRP to protect horizontal foam during backfill on FPSF. Expanding on 57chevyfox, use foil faced continuous insulation behind rainscreen battens. Foil tape seals seams permanently. I rip 1/2" pressure treated plywood into 2.5" strips and secure with galvanized ring shanks. 1" foam + 1/2" batten same thickness as 2x2 window and door bucks. One of these days I will have Charlie Wardell help me with an article.

I assume the outside wall is the load bearing wall? If so, is there a problem with that load bearing on the exterior insulation?

Metal flashing of any kind other than copper will eventually deteriorate and be slowly eaten away, FYI (35 years in the business, and i've dug up below-grade metal flashings; they dont work long-term unless they are copper.)