How to Hang Half-Round Gutters

This classic look is made even better with modern materials, but getting the installation details right is key for functional and good-looking gutters.

Synopsis: Remodeler Andrew Grace walks through the process of hanging half-round gutters, from locating the hangers in the right spots depending on the roof pitch, to hanging and joining the sections, to laying out and connecting the downspouts. Detailed drawings give tips for proper hanger and downspout layout.

It’s tough to improve upon the timeless look of half-round gutters. They were a natural fit for a 1919 farmhouse and garage we recently worked on. Although half-round gutters are also available in galvanized steel (least expensive) and copper (most expensive), my client chose aluminum, which is rust-free and more reasonably priced than copper. The 0.032-in.-thick aluminum gutters on the project are 6 in. wide with a durable, factory-applied finish.

Installing half-round gutters is a little more complicated than installing more conventional K-style gutters because the hangers are visible, so they must be evenly spaced and perfectly straight or the finished product will look terrible. This article, which covers an entire gutter and downspout installation, focuses on the tips and tricks that make the process faster and easier.

The first thing to keep in mind when you’re planning a gutter project is that a 5-in. half-round gutter can handle about half as much water as a 5-in. K-style gutter, so you need more downspouts or a larger gutter, and sometimes both. Proper sizing takes into account the roof dimensions and slope, as well as the heaviest rainfall you can expect for the project location. The gutter manufacturer we used, Berger Building Products, has helpful sizing information for both gutters and downspouts on their website (bergerbp.com). Labor and materials for this project came in at about $10 per ft.

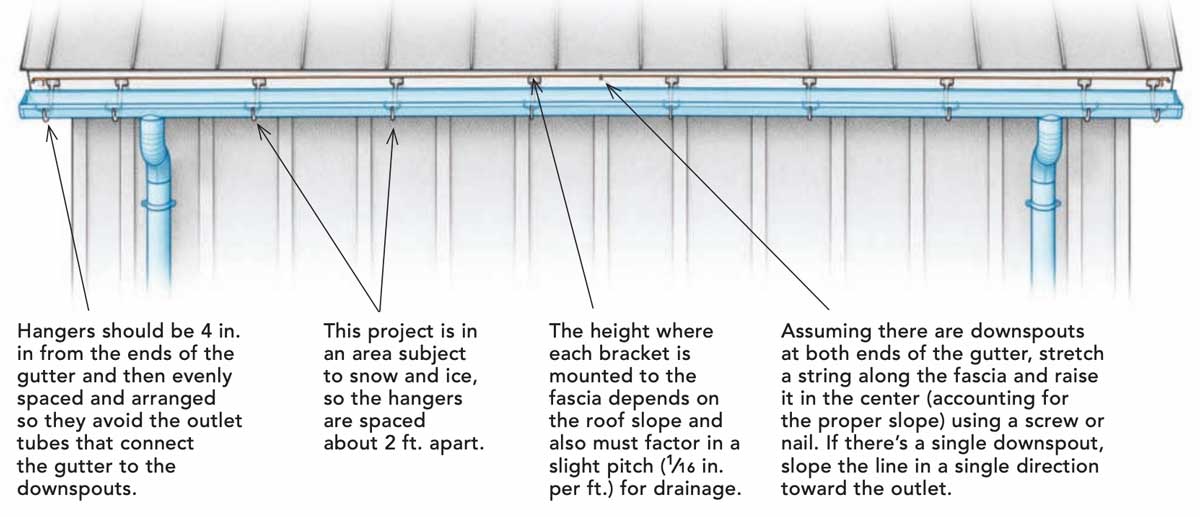

Get the hangers in the right spot

The manufacturer recommends that the gutter hangers be installed at a maximum of 36 in. on center to provide adequate support. In colder climates, where snow and ice could accumulate, they should be closer together. This building’s sloped fascia required adjustable hangers to hold the gutter in the right position, but hangers for straight fascia and exposed rafter tails are also available.

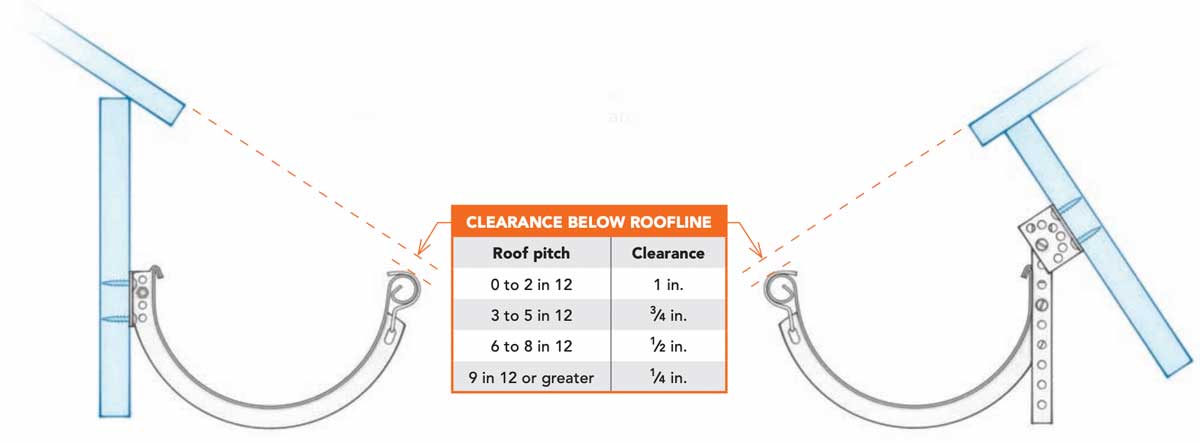

Roof slope guides mounting height

|

Plumb fascia Half-round gutter hangers should be mounted so that the gutter sits below the extended roofline, allowing snow and ice to slide over the gutter without getting caught. The distance below the extended roofline depends on the roof slope, with steeper roofs requiring less clearance than roofs with a lower slope. |

Angled fascia Mounting half-round gutters to an angled fascia follows the same clearance rules, but requires an adjustable hanger with an extended shank. Adjustments are made through trial and error, until the gutter sits level front to back. Once the adjustments on the first hanger are finalized, additional hangers |

Proper layout

Hang and join the sections

It’s impossible to fasten the hangers when the gutter is in place, so all the hangers must be mounted on the fascia before setting the 10-ft. sections of half-round gutter. Aluminum half-round gutter sections are joined with slip-joint connectors, aluminum gutter cement, and pop rivets. Steel and copper half-round gutters can be joined with slip-joint connectors or soldered.

|

|

|

Prep for joints. The straight hem at the rear of the gutter and the rolled edge at the front must be removed so the slip connector can be placed on the end of the gutter. 1 First, notch the edges with aviation snips. 2 Then, cut the pieces free with a miter saw using a carbide-tipped 80-tooth wood-cutting blade. 3 Test-fit the pieces (If the slip connector doesn’t fit, open it slightly with a straight screwdriver), and then place a 1⁄4-in. bead of aluminized gutter cement inside the connector and slide the pieces together, ensuring they’re fully seated with a bump from your hand. Wipe away any excess cement before it dries.

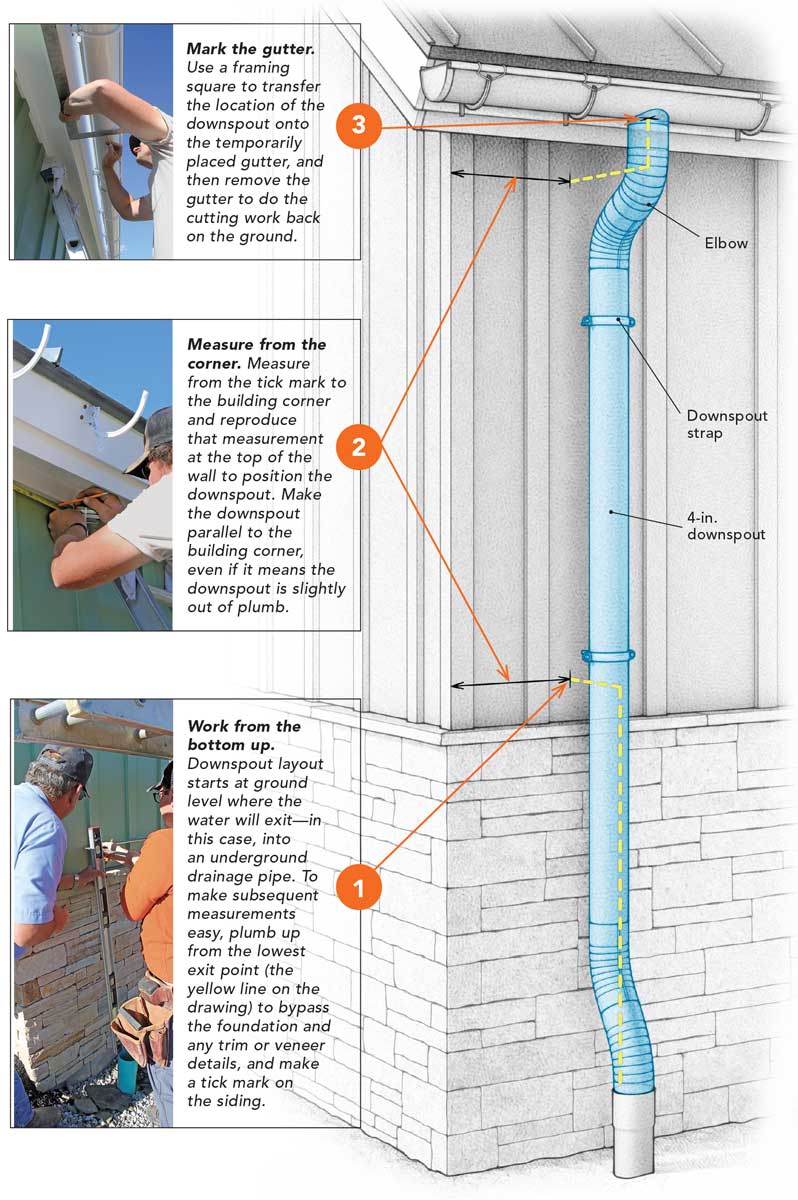

Prep for the downspouts

It’s easier to install the outlet tubes that connect the gutter to the downspouts on the ground rather than up in the air, but the most accurate way to locate the holes is by doing a test fit. If the gutters connect to an underground roof-water system, these pipes should dictate the downspout layout in order to minimize offsets and extra fittings. The process starts at the bottom.

Lay out & cut perfect holes

Connect the downspouts

Smooth and corrugated downspouts are available in galvanized steel, copper, and aluminum in diameters ranging from 2 in. to 7 in. There are also several types of downspout hangers with mounting options suitable for all types of wall cladding. It’s important to have enough downspouts in sufficient diameter to handle all the water expected in a heavy rainfall. Gutter manufacturer websites can help with proper sizing of both gutters and downspouts.

Custom fit elbows

Andrew Grace is a remodeler in Ligonier, Pa. Photos by Patrick McCombe. Drawings: Christopher Mills

From Fine Homebuilding #274