Replace the Cord on a Power Tool

Here's how to breathe new life into a drill with a frayed cord.

This right angle drill, bought in 1995, is great for mixing mud and especially great for drilling holes for pipes and wires. But as with any corded tool, eventually the cord succumbs to the wear and tear of the job site. In this episode of ToolTech, Patrick McCoomb takes the tool apart and replaces the cord.

The first step is to split the two halves of the drill housing. Then, after opening the case, Patrick snips the wires leading to the power cord, strips and trims then, and then uses butt connectors to join them to the new cable. He is careful to slip the strain relief into the right spot. Then the case is closed, and the tool is repaired.

Keep in mind that if you are a pro and you have employees using your tools, you have to use exactly the right replacement part, by the part number, to make your repair, or you may find that you have made an OSHA violation.

Senior editor Patrick McCombe has been testing power tools on behalf of national publications for more than 15 years, and he regularly meets with product manufacturers to try out new introductions. In the Tool Tech series, Patrick reviews the latest tools and materials, discusses building technology, and shows time-tested techniques for better, more-efficient home building. Consider becoming an online member to watch other Tool Tech videos.

View Comments

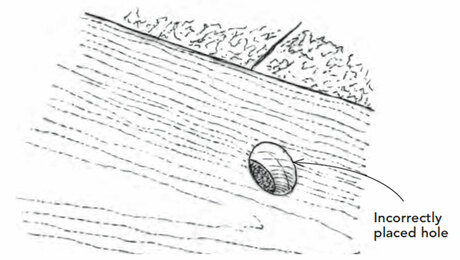

A simple repair, that all of us have done at one time or another. Just a good reminder to just go and do it so you are not making the cord a mess with electrical tape patches. It is too bad during reassembly - he installed the cord clamp inside the handle upside down, now placing added pressure to the conductors from the edges of the clamp that are backwards.

The cord clamp was installed upside down. Also, I don't understand why splices were made inside the handle when the setscrew for the wire attachment to the switch was clearly visible. The switch should have been removed and the cord attached directly to the switch.

I totally agree with both previous posts. Many newer tools do not have the extra room for butt splices. Proper method would have been to go directly to the switch. Maybe he should have taken a picture of the stock tool's wiring and would have avoided installing the cord clamp upside down.

Who made the crimping tool?

I've replaced cords on a number of my power tools - with Hilti 4m long flexible cords that I managed to get my hands on. The reason that I replace old cords is not because they are frayed. It's because the cords that most manufacturers put on tools are way too short (even for use in the shop) and they kink. "When will they ever learn?"

FHB will shortly be advertising for a Manager, Video Quality Control :)