Quartersawn Wood and Rift-Sawn Wood, Explained

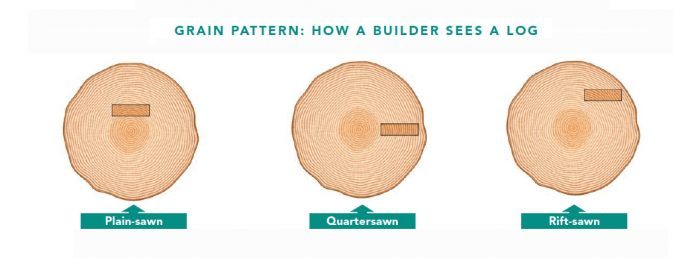

The easiest way to quickly assess different cuts of wood is to look at the end grain.

See illustration below for more information

I do some custom interior work for clients from time to time, and despite years of shopping at various wood suppliers, I’m still confused about the difference between what some sellers label as quartersawn wood, and what they label as rift-sawn wood. I looked at diagrams online, and now I’m even more confused. Is there really any difference?

—Ken, via email

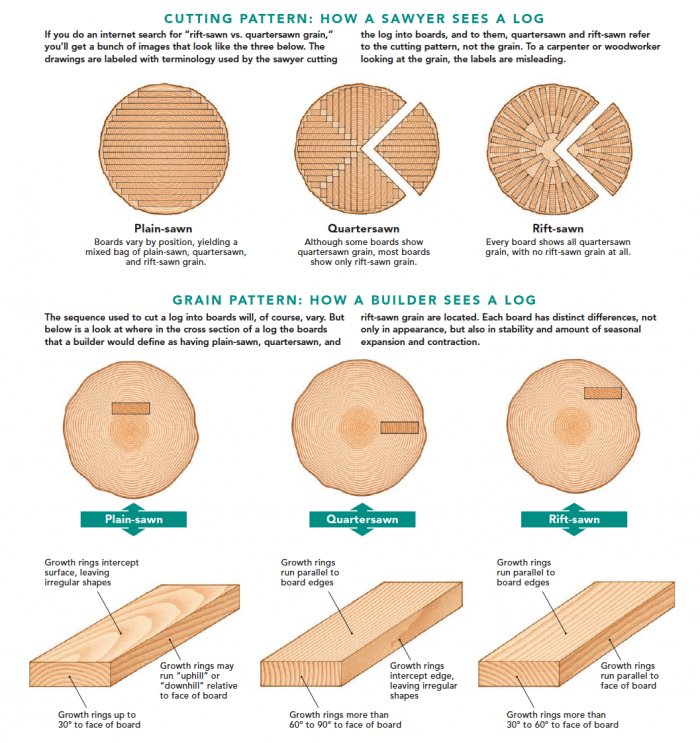

Editor Justin Fink replies: This confusion is widespread, and I think it mostly stems from the fact that quartersawn means one thing to a sawyer cutting a log into boards, and another to the person, like you, who is buying a board cut from that log. But before we get into all of that, let’s go over the generally accepted definitions.

The easiest way to quickly assess different cuts of wood is to look at the end grain. A board with growth rings running roughly parallel—usually in arches—relative to the face of the board is called a plain-sawn (or flat-sawn) board. If the growth rings are at a steep angle relative to the face, the board is said to have quartersawn grain. If the growth rings run at a slightly lower angle, it’s called rift-sawn. The reason for the different cuts is that compared to plain-sawn boards, both quartersawn and rift-sawn boards are less likely to cup, and will experience less seasonal expansion and contraction across their widths. There are also notable differences in appearance, which is important to a carpenter or woodworker. Quartersawn lumber will have straight, uniform grain on two sides—the top and the bottom. Rift-sawn lumber will have that same straight, uniform grain on the top and bottom, but will also have nice parallel grain on the two edges.

From the sawyer’s perspective, quartersawing a piece means slicing a log into four quarters, and then each of those quarters is set flat and cut into pieces at a 45° angle. It’s less common, but the sawyer might also choose to rift-saw (often called rift-cut) a log. In this case, the log is cut into a similar-looking set of four quarters, but then each of those quarters is rotated between cuts. Compared to plain-sawing a board, both quartersawing and rift-sawing will indeed yield less usable lumber, and may require a lot more handling, hence the higher cost.

Unfortunately, the drawings floating around the web that show this difference in cutting technique are often mistakenly used to illustrate the difference in the boards themselves, which leads to confusion. Quartersawing a log will yield some quartersawn boards, but it will also yield some rift-sawn boards, and some boards that have a mixture of both (often called mixed grain). Rift-sawing a log, however, will yield all quartersawn boards, and no actual rift-sawn boards, and that is why many people get confused.

View Comments

Am I missing something? According to the graphic at the top, a rift-sawn log would yield almost all 90-degree growth rings, but at the bottom the picture for rift-sawn boards shows 30-60-degree growth rings. Now I'm really confused.

Sincerely, Leonard Sepp

I believe the last diagram is mislabelled -

quartersawn rift-sawn are reversed.

Thanks, I was going to make the same comment.

They are trying to show the difference in what a sawer calls rift or quarter vs what a builder/carpenter calls rift or quarter. One looks at the log before it's cut and where the boards come out of the log. The other looks at the resulting grain pattern so the second drawings are not mislabeled. That said, some internet sites show the first rift log cutting diagram as 'true quarter' and does produce quarter sawn not rift sawn boards. So the written descriptions are misleading and are trying to say that the boards in the corners of the quarter sawn log will have more rift grain. Is it any wonder the longest lasting homes are built from the whole log! ;-)