Simple Sawhorses

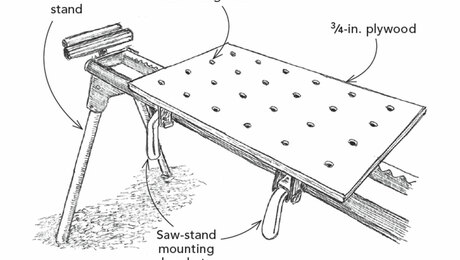

These knockdown sawhorses are far easier to move from job to job than a conventional sawhorse.

I first learned how to make these sawhorses 37 years ago from Karl Kulrich, a cabinetmaker who emigrated from Germany to Whitehorse, Yukon in Canada. Karl was a clever older gentleman who taught me a lot and shared many of his tricks of the trade.

One of my favorite of Karl’s creations is a method for building knockdown sawhorses that are far easier to move from job to job than a conventional sawhorse, and don’t sacrifice any of the strength.

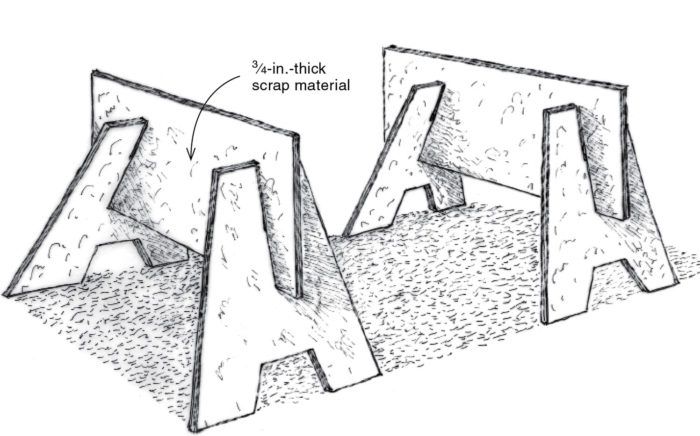

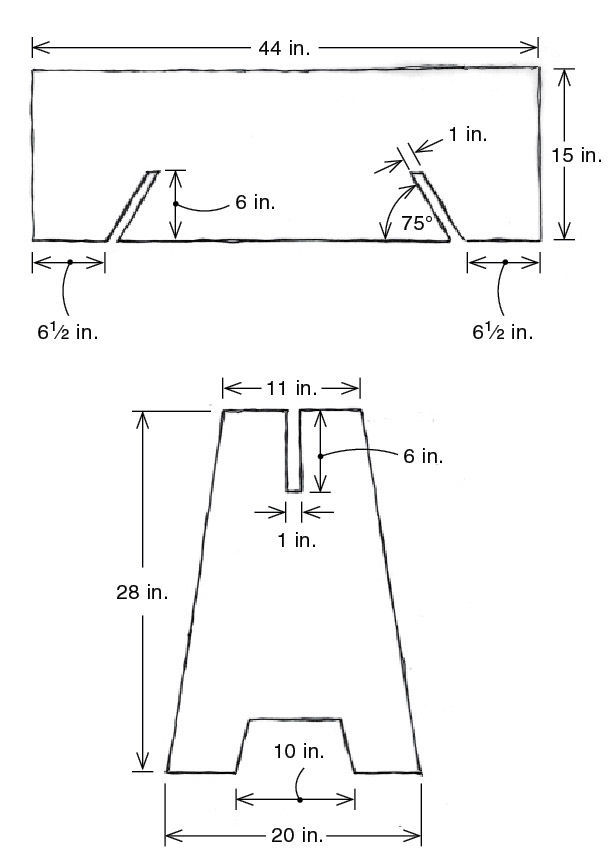

The pieces are made from 3⁄4-in.-thick scrap material, and as you can see from the drawings, they fit together with no fasteners, so assembly and disassembly are fast and easy, and the setup breaks down to a transportable size.

— Rudy Verhoeven; Fraserville, Ont.

From Fine Homebuilding #277

RELATED STORIES

Got a Tip?

Do you have any great tips like this one on how to make a sawhorse? Share your methods, tricks, and jigs with other readers. Tag them @FineHomebuilding on social, email them to us at tips@finehomebuilding.com, or upload them to FineHomebuilding.com/reader-tips. We’ll pay for any we publish.

View Comments

Nice article

I've used just about every type of sawhorse pictured in the larger article from which this design is drawn.

(If memory serves the idea for them came from a Fine Woodworking book --"The Bandsaw Book" by Mark Duginski.) In my experience no other design is as practical, lightweight, compact to store and transport or as useful as this one. Though it is a minor complaint it does take awhile to get used to the fact that when you pick an assembled horse up it's best to grab it by the tops of the legs. Otherwise you will spend plenty of time reassembling them. This can be somewhat offset by making the joints as tight as possible though I also think the wide top piece specified here will help to make these very stable as well as prevent the legs from slipping out when casually lifted. I've always made mine with that piece no more than 6" wide. Most were of 3/4" plywood. However, once when I was left with several scraps of 1 1/8" subfloor material, I made several heavier horses from that material. They have become favorites. I also make a shorter horse than these of the same design. All have had hard use in home renovation projects, light construction, remodeling work and in theatrical set building applications.