Podcast Episode 134: Painting Kitchen Cabinets

Sealing sanded-grout scratched tile, updating outdated kitchen cabinets, and foundation options for a shed on a sloped lot.

The guys take a deep dive into the options for updating outdated kitchen cabinets before turning to questions on scratched tile and foundation options for a shed on a sloped lot.

Question 1 from Dwayne:

I recently bought a town house that was built in 1983 and the kitchen, with the wood grain laminate, needs an update.

My plan for the cabinets is to paint the face frames and boxes and use a connection I have at the local trade school to have new shaker style doors made and painted. Saving on cost and giving the students an opportunity to learn something different. As a past graduate I would have enjoyed a project like this.

My questions for you are:

- What product do you recommend to paint the face frames, boxes and new doors?

- When measuring and planning out the new doors, what should I look out for or be sure to consider? i.e.spacing between doors (I would like the new doors to have the largest over lay possible)

- What would be the best material to have the doors constructed from? Rails & stiles and the panels (low cost but durable)?

Thank you for your valued opinion, and I hope i didn’t leave you needing more information

Question 2 from Patrick:

I’m newer to the FHB podcast, but have gone back and started listening to previous shows to try to catch up. In a previous episode, you briefly talked about the difference between sanded and unsanded grout. One of the things that was mentioned was that sanded grout can sometimes damage the surface of porcelain, ceramic, and glass tiles. Wish I would have started listening a long time ago…

If someone, hypothetically of course, already used sanded grout on floor tiles that may have cause slight scratches, is there a remedy for the problem? The damage isn’t visible initially, but the floor tiles are white and quickly become stained after cleaning them thoroughly. Is there a sealant or something that can be applied when the tiles are clean to keep them from staining so easily and protect the finish? Any thoughts or suggestions are appreciated!

Gave you guys a 5-Star rating on iTunes cause you deserve it!

Question 3 from Tom:

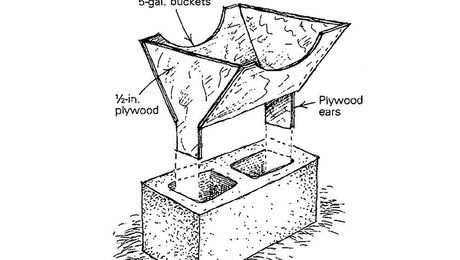

I’m building at 14×14 shed and was planning to do 2×8 L-joists on 2.5” solid concrete blocks on gravel at 12 points for the base. This is code in my area up to 200 sq ft. After measuring up the site, I found that the largest height differential between two points is about a foot, so too far to make up and keep the blocks under 3 high. The shed will be located next to a large tree, so deep footings or a slab isn’t an option. Under each point I dug a roughly 2’ diameter hole 8” deep and filled with 3/4” gravel. The main point of the shed is to cover pool equipment so the location isn’t subject to change. My question is about the foundation construction in which I’m leaning towards 12” diameter on-grade piers poured on the gravel in a Sonotube:

- Is there any height restriction? For example if the smallest pier is 6” high, the tallest would be 18” high.

- Should I attach with a J-bolt as long as I’m pouring the piers, or is there any benefit in regards to movement in just placing the L-joists on the piers as I intended to do with the blocks.

This episode of the podcast is brought to you by Benjamin Moore and OLFA.

This episode of the Fine Homebuilding podcast is brought to you by Benjamin Moore. Everyone can paint. This is true. But not everyone can get the project done right. And Benjamin Moore knows that’s why you’re on the job. You’re more than a paintbrush and a ladder. Your client can buy those things at a hardware store, but they hired you for your skills and expertise. You know every paint job is different and that it takes more than one coat for the best finish. Benjamin Moore believes in doing things the right way. Because everyone can paint, but to do it right, it takes an expert contractor, it takes more than one coat and it takes Benjamin Moore. Paint like no other.

This episode of the Fine Homebuilding podcast is also brought to you by OLFA. It’s time to upgrade your blade to a new OLFA Contractor Grade X-Design utility knife. Make blade changes quick and easy with OLFA’s super-strong snap-off blades. Work 25% sharper with their pre-loaded Ultra-Sharp, Black carbon steel blades. And work stronger with the durable fiberglass-reinforced anti-slip grip handles. Find OLFA X-Design in three contractor grade sizes: extra heavy-duty 25 mm, heavy-duty 18mm, and high-precision 9mm. Ditch your old knife and learn how to upgrade your blade at OLFA.com/FHB.

We hope you will take advantage of a great offer for our podcast listeners: A special 20% off discounted rate to subscribe to the Fine Homebuilding print magazine. That link goes to finehomebuilding.com/podoffer.

The show is driven by our listeners, so please subscribe and rate us on iTunes or Google Play, and if you have any questions you would like us to dig into for a future show, shoot an email our way: [email protected]. Also, be sure to follow Justin Fink and Fine Homebuilding on Instagram — and “like” the magazine on Facebook. Note that you can watch the show above, or on YouTube at the Fine Homebuilding YouTube Channel.

The Fine Homebuilding Podcast embodies Fine Homebuilding magazine’s commitment to the preservation of craftsmanship and the advancement of home performance in residential construction. The show is an informal but vigorous conversation about the techniques and principles that allow listeners to master their design and building challenges.

Links for this episode:

- All FHB podcast show notes: FineHomebuilding.com/podcast.

- #KeepCraftAlive tee-shirts support scholarships for building trades students. So go order some shirts at KeepCraftAlive.org.

- The direct link to the online store is here.

View Comments

The precast piers discussed in the show are called EZ Tubes. Check this website - https://www.ez-crete.com/products/ez-tube/

I think they are available at HD.

I've used these heavy plastic piers and they worked well:

http://redifooting.com/

This is a Rhode Island company without wide distribution just RI, Mass., and CT

If Fink leaves too Im done with this podcast.

@GGman57 Looks like those precast piers are mainly sold in the NE US.

Be very careful with cheap box fans and flammable fumes.

I've done a few kitchen cabinet projects. cleaning,sanding, filling holes (bondo or wood filler) and then oil stain block is key prep. I'd recommend mini-rolling face frames with back brushing. I highly recommend Ben Moore Advance. I used the Advance primer after the oil stain block and then two coats of Advance top coat. Sanding with 220 or higher between coats. Spraying drawer fronts and doors has a better finish than rolled/ back brushed IMO.