Choose the Right Primer for Your Next Painting Project

Get the lowdown on the four most common formulations, and an overview of specialty primers for every possible substrate and situation, so you can find the right product for the job.

Synopsis: For this article, senior editor Patrick McCombe consulted experts from Sherwin-Williams, Dow Coating Materials, and Benjamin Moore, as well as FHB’s most-trusted painters. The result is a comprehensive look at a product that is never seen in finish work but is crucial for the longevity of that finish work. McCombe discusses the four main formulations of primer—oil-based, water-based, shellac-based, and synthetic shellac-based—as well as a product that hit the market relatively recently: paint and primer in one. He also provides helpful information on “do it all primers” and 11 specialty formulations: rusty-metal primer, vapor-barrier primer, problem-drywall primer, gray-tinted primer, PVA primer, high-bond primer, mold-killing primer, concrete-and-masonry primer, low-VOC primer, peel-bonding primer, and drywall primer.

Primer is one of those everyday building materials I’ve never given a lot of thought to. I’ve always used latex primer because it dries fast and is easy to clean up, but a quest for a durable exterior paint job on some basement bulkhead doors convinced me that I needed to know a lot more about the primer I use. So in the interest of science and a longer-lasting paint job, I interviewed primer experts from Benjamin Moore, Dow Coating Materials, and Sherwin-Williams. I also talked to Fine Homebuilding’s most-trusted painters about what they use and why. I’m grateful for everybody’s help, and I was surprised by the consistency of their advice. Here’s what I learned.

Primers Have a Specific Job

Primer and paint have different jobs, and they’re made differently for that reason. Primer prepares a surface for a topcoat and improves the topcoat’s adhesion. Paint sticks to the primer and provides color, dirt resistance, and weather resistance. As part of its job, a primer may have to cover or seal in stains, level an uneven surface, or effectively stick to smooth or glossy surfaces. This wide range of needs is what gave birth to all of the specialty primers you can now find on store shelves.

Unlike a topcoat, primer isn’t made for long-term exposure. It doesn’t have the same resistance as paint to UV rays, mold, weather, pollution, and job-site wear and tear, so you shouldn’t leave it exposed for any longer than necessary, especially outdoors. Generally speaking, more expensive primers cover better and hold up better than less expensive primers because they have higher-quality resins as well as additives such as mildewcide, according to Benjamin Moore field integration manager Mike Mundwiller.

Because primers aren’t supposed to be exposed to the weather for a long time, any primer that’s been outside for more than a few weeks should be lightly sanded, thoroughly cleaned, and reprimed. Some primers have a sweet spot for when they’re best topcoated. This is spelled out—along with the expected coverage, the recommended application thickness, and the final film thickness—in the individual primer’s product data sheet or technical data sheet. You can find this information at a paint store and on paint manufacturers’ websites. Product data sheets are also the best sources for minimum and maximum application temperatures and other application instructions.

Primer can be applied with a brush, a roller, or a sprayer. What tool to use depends on the size of the job. For small jobs, a brush is best because it’s fast to deploy and easy to clean. Rollers are for medium-size jobs, and sprayers are for large jobs. When spraying, my experts suggest going over the sprayed primer right away with a brush or roller to ensure that there are no tiny bare spots.

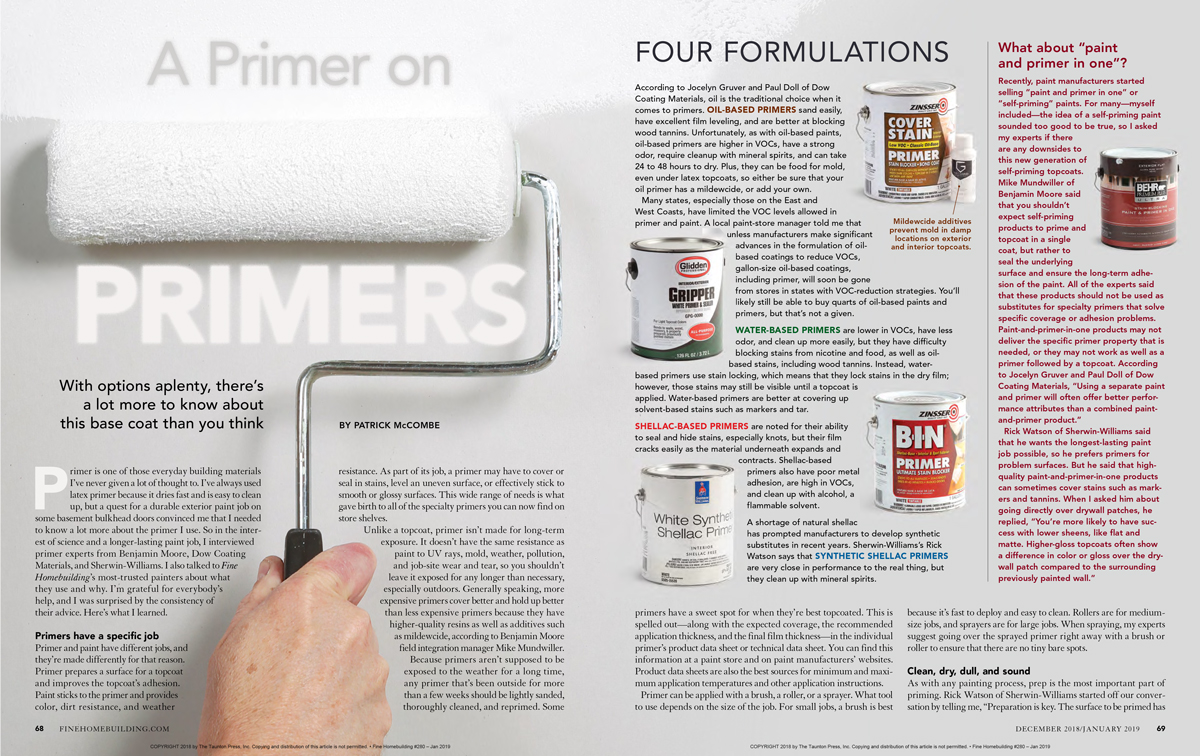

Four Formulations

According to Jocelyn Gruver and Paul Doll of Dow Coating Materials, oil is the traditional choice when it comes to primers. Oil-based primers sand easily, have excellent film leveling, and are better at blocking wood tannins. Unfortunately, as with oil-based paints, oil-based primers are higher in VOCs, have a strong odor, require cleanup with mineral spirits, and can take 24 to 48 hours to dry. Plus, they can be food for mold, even under latex topcoats, so either be sure that your oil primer has a mildewcide, or add your own.

Many states, especially those on the East and West Coasts, have limited the VOC levels allowed in primer and paint. A local paint-store manager told me that unless manufacturers make significant advances in the formulation of oil-based coatings to reduce VOCs, gallon-size oil-based coatings, including primer, will soon be gone from stores in states with VOC-reduction strategies. You’ll likely still be able to buy quarts of oil-based paints and primers, but that’s not a given.

Water-Based Primers are lower in VOCs, have less odor, and clean up more easily, but they have difficulty blocking stains from nicotine and food, as well as oil-based stains, including wood tannins. Instead, water-based primers use stain locking, which means that they lock stains in the dry film; however, those stains may still be visible until a topcoat is applied. Water-based primers are better at covering up solvent-based stains such as markers and tar.

Shellac-Based Primers are noted for their ability to seal and hide stains, especially knots, but their film cracks easily as the material underneath expands and contracts. Shellac-based primers also have poor metal adhesion, are high in VOCs, and clean up with alcohol, a flammable solvent.

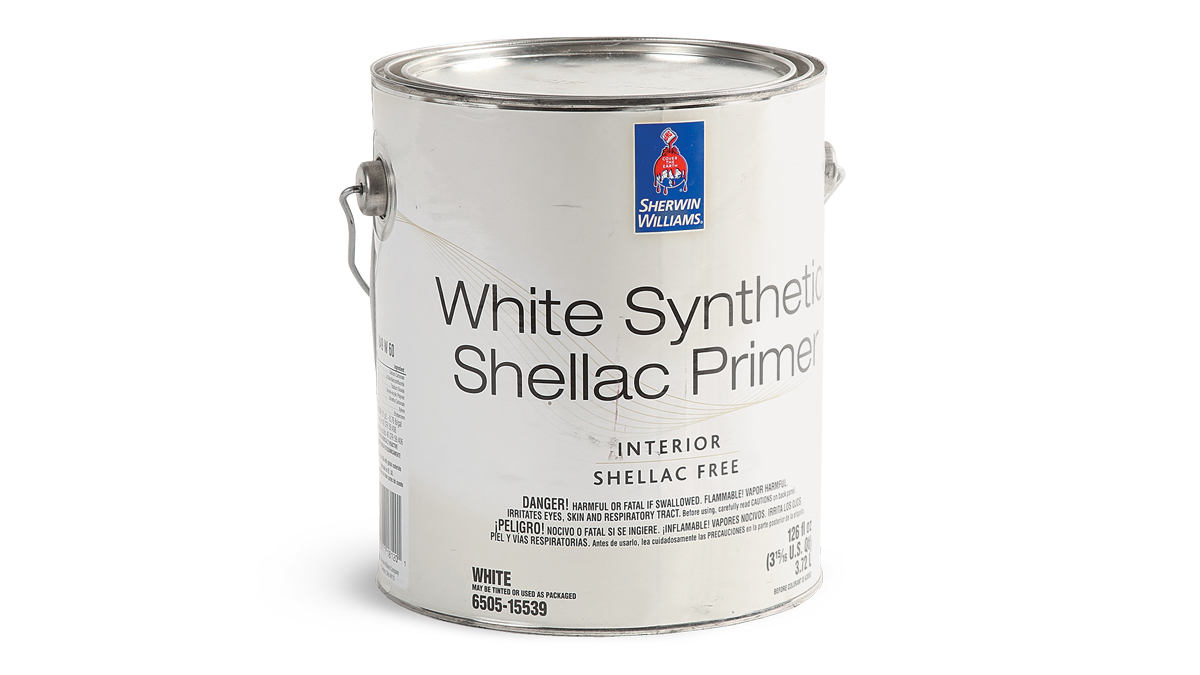

A shortage of natural shellac has prompted manufacturers to develop synthetic substitutes in recent years. Sherwin-Williams’s Rick Watson says that synthetic shellac primers are very close in performance to the real thing, but they clean up with mineral spirits.

Clean, Dry, Dull, and Sound

As with any painting process, prep is the most important part of priming. Rick Watson of Sherwin-Williams started off our conversation by telling me, “Preparation is key. The surface to be primed has to be clean, dry, dull, and sound.” Clean means that the surface is free of contaminants that would affect the primer’s bond to the underlying surface. Dry means that the surface is not only dry to the touch but also that the moisture content of the material is within the tolerance of the primer. Dull means that the surface has been sanded or otherwise prepared to increase the primer’s bond. Sound means that any underlying coating is sufficiently bonded to the substrate; how well the primer sticks to the previous coat of paint doesn’t matter if that paint is poorly adhered to the material below.

If you’re worried that an existing coating doesn’t have a good bond, complete paint removal is the safest bet. Obviously, that’s not always practical, so thorough scraping or sanding is the best alternative. If you do need to scrape or sand, be sure to clean the surface thoroughly before priming. Best practice is to power wash after moderate or heavy scraping, but many painters power wash first because the stream of high-pressure water removes much of the old paint. That’s OK, but they may have to wash again if there’s additional scraping. Allow enough time after washing for the surface to dry thoroughly.

What About “Paint and Primer in One”?

Rick Watson of Sherwin-Williams said that he wants the longest-lasting paint job possible, so he prefers primers for problem surfaces. But he said that high-quality paint-and-primer-in-one products can sometimes cover stains such as markers and tannins. When I asked him about going directly over drywall patches, he

replied, “You’re more likely to have success with lower sheens, like flat and matte. Higher-gloss topcoats often show a difference in color or gloss over the drywall patch compared to the surrounding previously painted wall.”

Keep it Cool

My experts say that in the summer you should apply primer in cooler temperatures and move your work around so that you stay in the shade. Keeping out of the sun slows the drying process, which helps the primer to penetrate the surface for better adhesion and improved long-term durability.

Slow drying is especially important when priming bare wood

because the primer needs time to penetrate into the wood fibers for a good bond. My experts recommend slow-dry oil primers because they stick better. It may be tempting to move a project along with

a fast-dry primer, but those products are not as thorough at penetrating the surface for a good bond. Interior primers are less susceptible to UV damage and dirt and can be left exposed longer; however, it’s still good practice to apply a coat of paint over these products as soon as possible to minimize the chances of dust compromising the topcoat’s bond.

Do–it-All vs. Specialty Primers

In recent years, paint companies have been touting their do-it-all primers. According to Gruver and Doll of Dow, painters and DIYers don’t want the hassle of buying 10 different primers for 10 different jobs, so manufacturers have responded with what are described as “multipurpose primers.” These primers, which are available in both oil and latex versions, have additives that improve their bond, hiding ability, and mold resistance. They can’t solve all the problems a painter encounters, but they are making it easier to address multiple problems with a single product.

Specialty primers can boost adhesion, smooth damaged drywall, prepare surfaces for wallpaper, and even help dark topcoats cover better. Prices range from about $15 to about $50 per gal., but primer is not one of the products you want to buy on price. The cost of primer is so little compared to the cost of a home improvement or painting project, and having to fix a problem paint job because you skimped on the primer is going to be far more costly than spending a few dollars on the right high-quality primer.

Rusty-Metal Primer

Designed for steel and iron, oil-based rusty-metal primers are designed to slow rust formation. This manufacturer claims that the product has superior adhesion for better resistance to cracking, peeling, and chipping and that it minimizes the need for additional topcoats.

Gray-Tinted Primer

For dark topcoats to better cover light-colored previously painted surfaces, most primers can be tinted with black pigment. Gray primer is also an option, and because it comes tinted, you don’t have to wait for someone at the paint counter to add black colorant and shake the can.

PVA Primer

Among the least expensive primer options, PVA primer is only designed for a single task: priming bare drywall under flat or matte paints. The polyvinyl acetate formula evens the porosity of joint compound and the drywall’s paper face so that subsequent coats of primer or topcoat cover evenly.

High-Bond Primer

Any paint can have difficulty bonding to slick, previously painted surfaces. These especially sticky primers can eliminate the need to sand those problematic surfaces and are the best choice if you’re dealing with painting over glossy paint, tile, melamine, or laminate.

Mold-Killing Primer

This primer has a mildewcide that kills mold, fungi, and odor- causing bacteria, but you still have to clean the surface. The technical data sheet says this: “Physically or mechanically remove gross filth, heavy soil, overgrowth or loose material including dirt, grease, and oily films before application.”

Vapor-Barrier Primer

Vapor-barrier primers can replace kraft-paper-faced vapor retarders on batt insulation or polyethylene sheeting behind the drywall. When applied at the recommended coverage rate (3.8 mils wet), this product has a perm rating of 0.58, making it a Class II vapor retarder, which allows some drying.

Problem-Drywall Primer

Ever destroy the paper face of drywall when removing wallpaper from improperly prepared walls? The fix is a product like this, which prevents the paper from falling apart or blistering when it’s wetted by paint, more-conventional primer, or a skim coat of joint compound.

Concrete-and-Masonry Primer

It’s tough for primer to get a good bond on masonry and concrete, but products such as Tuffcrete are sticky and specifically made for bonding to those challenging substrates. Concrete-and-masonry primers should also tolerate efflorescence and high-pH levels.

Low-VOC Primer

Low- and no-VOC paints and primers are increasingly popular, as homeowners try

to reduce the smell and irritation that come with interior painting projects. Primers such as Greenguard Gold–certified Harmony wall primer from Sherwin-Williams has a VOC-free formula.

Peel-Bonding Primer

You used to have to either live with the rough surface caused by badly peeling paint, or resort to complete paint removal. Fortunately, the thick consistency of a peel-bonding primer can often smooth an alligatored surface without the expense and time commitment of complete paint removal.

Drywall Primer

Although they are more expensive than PVA primers, drywall primers are better for patches because, in addition to working on bare drywall, they also can be used over previously painted areas. These products contain more pigment than PVA, so they cover better and can be tinted for dark topcoats.

To view the entire article, please click the View PDF button below.

From Fine Homebuilding #280

RELATED LINKS