Fine Homebuilding’s Top 5 Tips & Techniques

Browse some of the best job-site solutions submitted by Fine Homebuilding readers.

Sometimes even the smallest issue can present a big problem and stop a job dead quick. Whether it’s a dull blade, missing tool, a large hole in some drywall, or some other issue, ingenious and resourceful builders have developed certain tips and techniques to get the job done. When time is money, and it always is, leaving a job to get a store-bought solution often isn’t a viable option. Finding the fix with what’s on hand or creating a better way to get the job done is often just what builders need to do. And, saving the day is how most of Fine Homebuilding‘s reader-submitted Tips & Techniques have come to be, but some are simply crafty ideas that are just too good not to share. For years, each issue of Fine Homebuilding has shared Tips & Techniques from its readers with its readers. Below are five of our favorites.

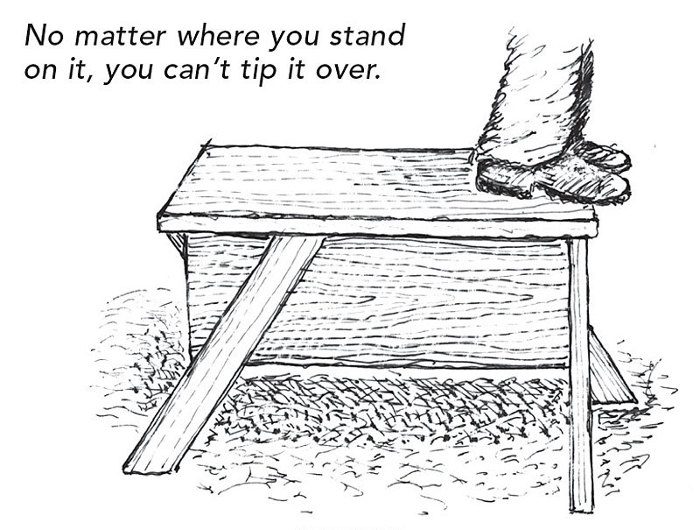

5. A No-Tip Stool

At the age of 10, I was taught to build this step stool by my 85-year-old neighbor. That was 51 years ago, and no matter where on this stool I stand, even near the edge, it will not tip. The key is how the legs splay from the corners at about a 30° angle.

John Lockwood, Clarksburg, NY

from Issue 258

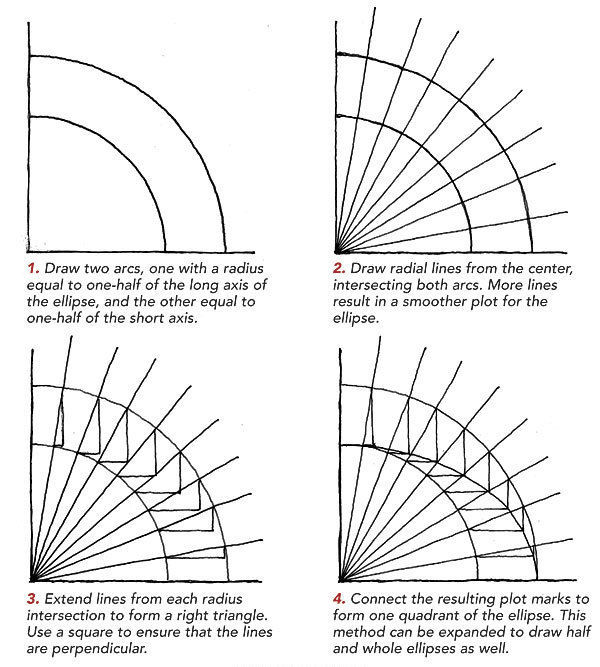

4. A No-Math Method to Draw an Ellipse

Here is a no-math way to lay out an ellipse. It works especially well if you need to draw the curve on the working material.

Peter Wells, Glendale, WI

from Issue 216

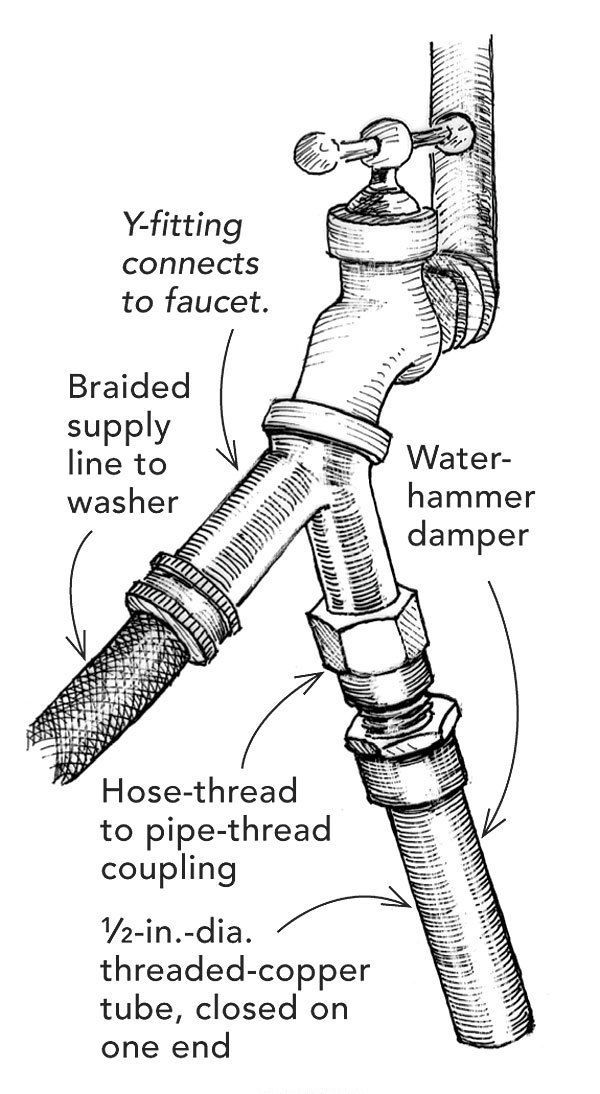

3. A Simple Cure For Water Hammer

I recently changed the water hoses on my clothes washer from the all-rubber type to a new style with a braided-metal covering. The next time I used the washer, a loud bang resounded when the water turned off. The all-rubber hose is much more expandable than the metal type. Being more expandable, the rubber type dampens the pressure surges that cause water hammer.

At the hardware store, I bought a couple of water-hammer dampers, 4-in. lengths of copper tubing closed at one end and threaded on the other. Inside, an air chamber dampens pressure surges. The instructions said to cut into the copper water lines and to solder in T-fittings to mount the dampers. I figured out a way to avoid that step.

At each faucet, I installed Y-hose fittings. Next, I attached a female hose thread to a female pipe-thread coupling on each Y-fitting, followed by a water-hammer damper threaded into each coupling. This solved the problem. The copper tubes will likely fill with water over time. When that happens, I’ll unthread them, pour out the water, and reinstall them.

Robert Tata, Huron, OH

from Issue 216

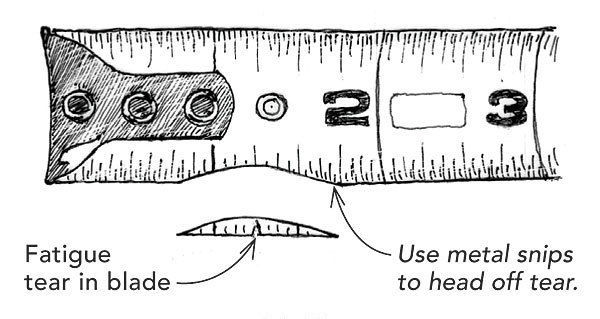

2. Tape-Measure Blade Rescue

Mike Guertin, East Greenwich, R.I.

from Issue 213

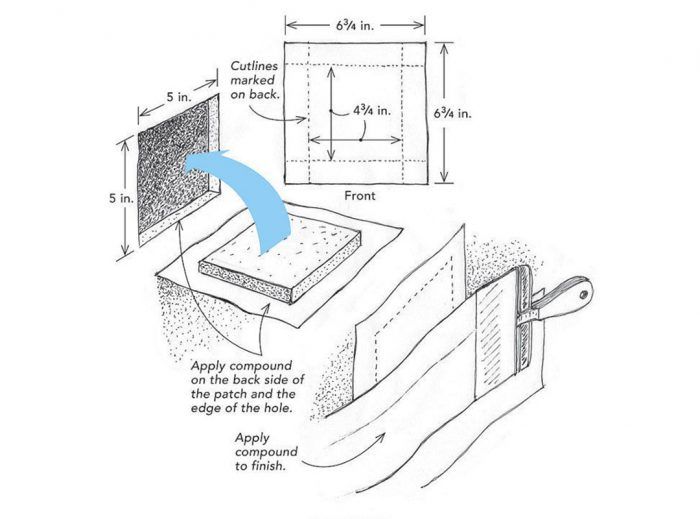

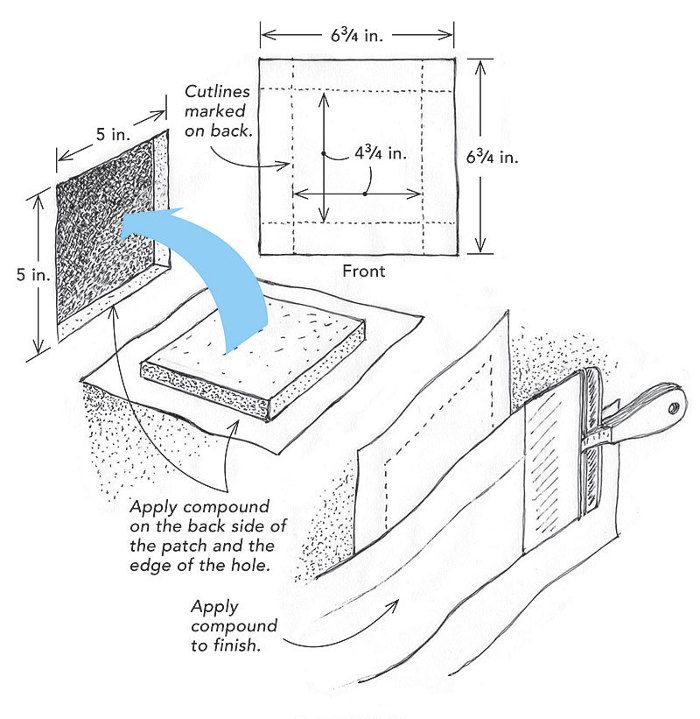

1. The No-Tape Drywall Patch

When working for a commercial/industrial builder and remodeler many years ago, I learned a simple method for patching drywall. It works on walls of any thickness and requires only whatever scraps of gypsum board are handy.

Square cut your hole as necessary—for example, 5 in. by 5 in. Cut your square patch of drywall about 1-3/4 in. oversize (6-3/4 in. by 6-3/4 in. overall). Flip the patch piece over, and score a 1-in. margin all the way around. Snap each of those scored lines one by one, and gently peel the gypsum off the face paper as you work your way around. You’re left with a patch piece about 43⁄4 in. sq. with a face-paper flange that eliminates the need for tape. The slight undercut in size gives you wiggle room so you don’t have to fuss with trimming, and it allows you to butter the inner edge of the hole and the outer edge of the patch piece for a tighter bond. The face-paper flange means no overlapping tape buildup to have to feather out. I’ve used this method for years with no apparent negative results. I think the advantage gained by eliminating the tape more than offsets the little extra time required to make the four perimeter cuts, which—like any often repeated task become almost instinctive.

Biff Crossley, Alloway, NJ

from Issue 244

— SUBMIT A TIP —

Do have your own great day-saving idea? If so, we’d love to see it and even pay you for it if we decide to use it in print. Email photos and a description to us at [email protected]; use the #FineHomebuildingTips hashtag on Instagram; or upload them to FineHomebuilding.com/reader-tips

View Comments

The water hammer fix will fill very quickly with water indeed. Whenever the tap is turned off the final dribble of water will run into the copper tube. It might fill and become ineffective even after one use. The copper tube should be vertical with the capped end at the top of the column.

Even when properly installed, the water will gradually absorb the air and the line will have to be drained and air allowed to fill the chamber again.